Fired Heaters Services

Fired Equipment is integrated into nearly every refining or chemical production process. Heat generated by combustion must be safely and efficiently transferred – typically through costly high alloy coils – to a process stream that may be changing phase or reacting. Fired Heaters usually generate the most challenging hydrodynamics, combustion & heat transfer, emissions, metallurgical safety issues, and potential constraints to your profitability.

Do you have a good handle on all your heater limitations and constraints? Are you truly optimizing your run cycles to a safe and optimized limit? Do you have consistent and integrated programs including operating best practices, process monitoring, burner management, and mechanical integrity limits for your fired heaters? Becht brings a full suite of expertise to improve fired heater operations through field-based assessments and remote analysis.

Monitoring

Troubleshooting & Support

Training & Analysis

Monitoring

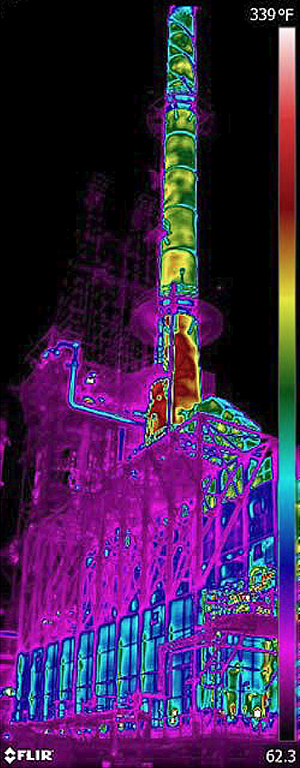

Advanced Infrared (IR) Monitoring Technology

Enhancing the capacity of critical heaters is becoming an industry trend. Accurate and repeatable tube metal temperature (TMT) monitoring is critical to meeting higher process demands within existing reliability constraints. Becht’s Advanced Infrared Monitoring Technology is best-in-class monitoring and data capture, allowing clients to safely and consistently run closer to true equipment design limits. Instead of being stopped by an undetectable hard-limit, you can manage the way you approach the true operating limit without exceeding it.

Our IR scan services are based on in-depth knowledge and worldwide field-proven experience in treating the complex issues of radiometry, target emissivity, surface conditions and flame interference. Our team developed these techniques over decades of field experience and experimentation working with chemical and refining companies. We consistently deliver data within 10o F, and often even closer, of true tube metal temperature (TMT) within operating fired equipment. Other IR scanning services only deliver data within 50o F of true TMT. With our more accurate data we help our clients safely run closer to true operating limits, capturing extra heater cycle length every time.

Our core team has a combined field experience of over 150 years with fired equipment. We provide IR scanning of process heaters, electrical equipment, refractory lined vessels, and any other process where accurate and repeatable temperature data is essential to help our clients maintain their production, integrity and reliability goals. Every scan also includes data analysis by experienced engineers to aid with interpretation of the data and actionable steps required based on the data while understanding an owner’s perspective for resource allocation.

Troubleshooting & Support

Troubleshooting Services & Fired Equipment Revamp

With evolving environmental norms over time, throughput enhancement requirements, and opportunity crude processing, it is common fired heaters become bottle necks and require review for thermal and hydraulic adequacy following changes to meet demand. We have an experienced team who actively support operating data analysis followed by evaluation of both hardware and operational options to reach optimal operation. We provide start to finish, one-stop solutions, starting with project development and supported through commissioning. We also troubleshoot underperforming heaters and work with our clients to implement the most cost-effective solutions with a relentless drive to operate safely and consistently to equipment design limits.

EPA MACT (Maximum Achievable Control Technology) Support

Since 2016 the EPA has rolled out mandatory requirements for refineries to maintain efficient fired heater operation. These mandatory requirements entail heater inspections and fine-tuning to meet both emission and efficiency requirements. Our organization supports achieving MACT with highly skilled professionals to fine tune fired equipment operation and prepare inspection reports in EPA preferred formats.

Training & Analysis

Combustion Training

Fired Heater Training is critically important to all levels of an organization to achieve safe and optimized heater operation. The operations team and their support groups need to understand how to safely operate and optimize heaters and need to be speaking the same technical “language”. We deliver onsite, hands-on training classes by lecturers who have mastered heater operation and understand heater design. Topics include basic combustion theory, heater efficiency, draft, burner operation, case studies of industry incidents, among others. Our team will help build a foundation for a common language for operating and optimizing fired equipment. Classes are tailored to the audience’s backgrounds and experience levels. We understand how operations teams will learn differently than engineers and we optimize our classes to maximize effectiveness.

Engineering Analysis

Becht Subject Matter Experts (SMEs) are previously high-level combustion and furnace experts from major refining and chemical companies. Our SMEs are familiar with problem solving for hundreds of styles and designs of fired equipment. Becht has access to world class expertise in all aspects of fired heater design, fabrication and operation including refractory, metallurgy, tube life assessments, creep analysis, burner management systems, fouling issues and furnace retrofit evaluation. We are the “A Team” to call in when an owner/operator needs a little more support to practically solve a complex problem.

Becht can handle the tough questions:

- Poor burner performance

- High temperature thermal expansion and support

- Correcting tube vibration problems

- Evaluating tube support designs

- Difficult corrosion and erosion issues that can lead to loss of containment

Our Fired Heater Services division can also build upon our ultra-accurate IR data for practical real time correlations based on firebox and process conditions to accurately estimate tube metal temperature. These simple models can help bridge to the next outage safely, when tube metal thermal couples can be repaired. They can be added to operating systems (DCS) so the correlation is in front of the operating team who can act. If needed Becht has the tools and the specialists needed for Computational Fluid Dynamics (CFD) modeling, Combustion modeling, Finite Element Analysis (FEA), pipe stress and code compliance. Becht specialists can work side by side with your staff to develop consistent and dependable programs for Risk Based Inspection (RBI), data gathering and tube life projection, and operating procedure validation.

Examples:

• Fired Heater Risk Ranking – Owners Can Mitigate Risks Of Operation

• Are Your Heaters Affecting Your Reliability?