Why do Clamped Connections With Metallic Seals Sometimes Leak?

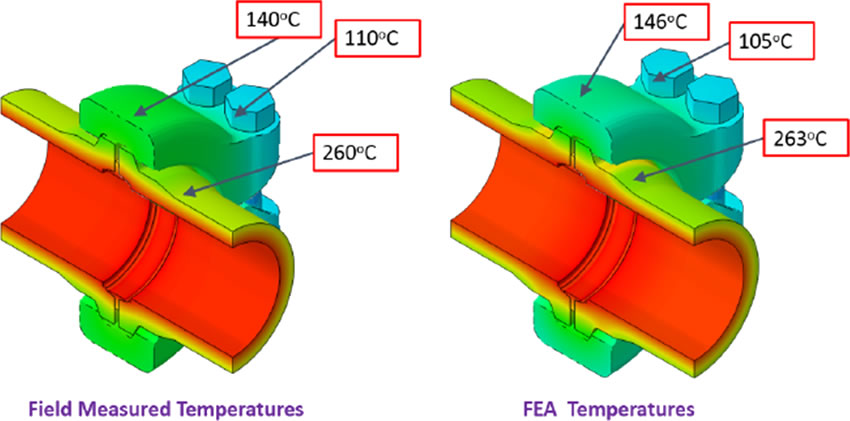

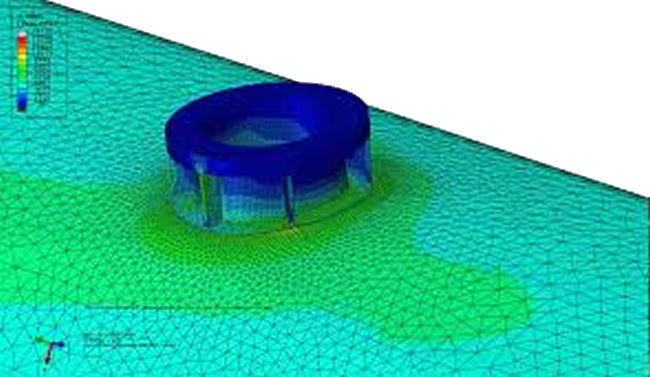

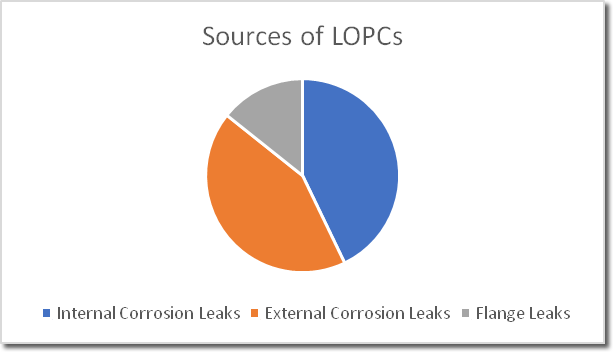

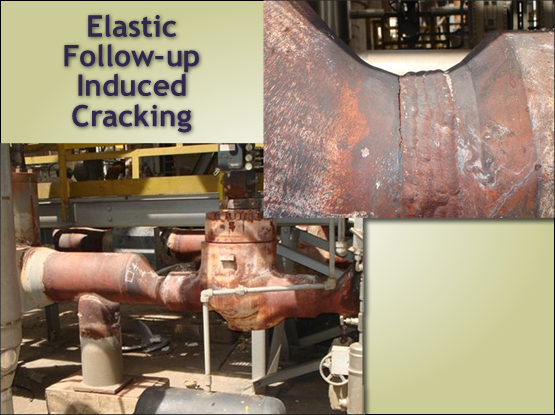

Clamp connections with metallic seals can offer superior joint integrity over traditional flanged connections but caution must be exercised regarding the service conditions, especially when cyclic thermal loading is present. This blog post highlights aspects of a clamp connection analysis performed by Becht Engineering. The client had observed significant loss of bolt preload at several […]