How To Manage A Crane Accident

No one expects to have a crane accident, but it can happen to anyone. Everyone who uses a crane is subject to a calculated risk. All of us need to be prepared in the event an accident occurs.

WHAT IF YOU ARE FACED WITH THIS AT YOUR SITE?

IMMEDIATELY ASSESS THE SCENE

Are there any injuries, trapped persons or fatalities? If so, notify Fire and Rescue immediately. Before they arrive, determine if any equipment or structures are unstable. Don’t let them walk into a trap and become victims!

Point out any known dangers including unstable structures to Rescue Personnel. Before and as they arrive, carefully explain any known hazards so the First Responders understand what they are dealing with.

Barricade the area in red to prevent any non-essential persons from entering a hazardous area. This also serves to preserve the site for investigation later.

THE RESCUE TEAMS WILL DOMINATE THE SITE

Be assured, they will dominate the scene until all injured are cared for and the site is safe for the public.

Has the Press showed up? Who will give them a statement?

Most companies have a PR Person but if it is you, give only facts. Do not speculate as the press will run with anything you say, and it will be major news within minutes. Any statements, correct or incorrect, can be used in court.

INITIATE AN INVESTIGATION

Contact the Insurance Company immediately. They will usually do an independent investigation.

Interview all actors and witnesses.

Don’t fire the operator – Yet. Get statements from everyone as soon as possible. The stories tend to change during the next few days and weeks. Don’t lead the witnesses. Even if the cause is seemingly obvious, be careful not to put words in the witness mouth. Let them tell their story.

Carefully examine the site and the crane.

Take pictures, careful measurements and record everything you see. Note things like boom length and angle, running and standing rope length and condition, outrigger extension and matting, if a load was attached and the final position, condition of the ground, and on and on and on. Something that may seem irrelevant may provide answers later.

Record all data from the crane computer.

The crane “data loggers” are like the “black box” on an airplane. They record everything the crane did including the weight lifted, radius, boom length, capacity at the time and if the safety systems were engaged or bypassed.

Consult the crane distributer or factory for this step. They are trained on the cranes computer systems and will also be a witness to the recovered data. If the crane is equipped with a “data logger”, they will have the software to down load the lift history.

On most cranes, the last configuration will be present when the key is turned on. Be careful not to lose this information. Do not turn on the key until the technician is in place. In most cases, after the key is turned on, the computer will reset to default after a few seconds or minutes.

Some crane accidents are minor in nature and are easy to figure out. Others can be very complex and will require weeks or months of forensic study to determine root cause. There may be some that will never be totally solved but you can narrow it down to a few possible causes.

REMOVING THE CRANE FROM THE SITE

This is the most complicated and hazardous part. There is no instruction manual for this. It is advisable to consult a Registered Professional Engineer. The engineer can calculate center of gravity for crane up-righting and design the complex unique rigging applications required for handling bent and broken components. Contact the insurance carrier before attempting to move anything.

DISASSEMBLE BOOM AND ATTACHMENTS

Many workers have been seriously injured or killed disassembling bent booms and jibs. Restrain all boom, jib and crane components before disconnecting. Then release the stored energy a little at a time until all the energy is completely released.

Do Not Just Cut It Loose and Let It Flop.

It may flop and hit someone (like YOU) causing serious injury or death.

CONTROL STORED ENERGY

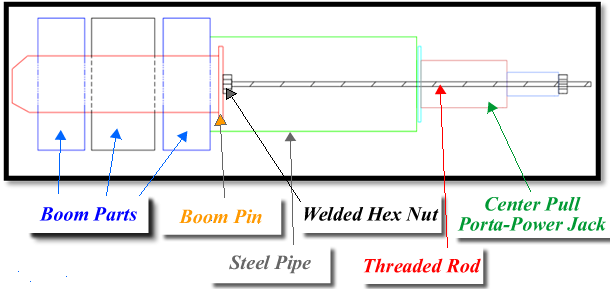

A mechanical “pin puller” can be easily fabricated to remotely remove boom pins while keeping a safe distance from any sudden release of energy or unexpected movement of the boom section. Use a long hose to maintain a safe distance.

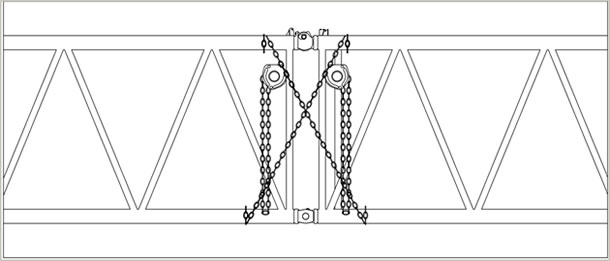

By attaching chain hoists (“come-alongs”) diagonally, as shown in the illustration below, on two sides; the stored energy can be gradually released by loosening one at a time until you see the direction the two parts begin to move. Then you can decide in what order to alternately relax the energy until the sections are safely separated.

An example of restraining a boom section (below)

UP-RIGHTING THE CRANE

It is necessary to understand where the center of gravity is before attempting to upright an over turned crane. In addition, it is necessary to adjust for any remaining components, such as boom sections, counterweights, etc. Be sure to use a hold back crane or device, of sufficient capacity, so the crane doesn’t topple over the other direction as the weight of the crane body passes top dead center. Many cranes are pulled over and collapse while attempting to up-right another.

It is always good to oversize the assist cranes to allow for an error on weight or sudden shock load.

Be sure to attach the rigging so it will not slip, cut or break off the section you are rigged to. Counterweights can fall off or be pulled off during the up-ending process. Carefully hoist up on the lift crane while keeping a light tension on the tailing crane.

The tailing crane will receive the weight as the center of gravity passes top dead center.

While upending the machine, as you raise the hook on the up-righting crane lower the hook on the hold back crane at the same time. Be careful not to overload either crane. It is a good practice to initially maintain a little slack on the hold back crane until you see the rigging start to take load. That indicates the center of gravity is close to or past top dead center. Once the hold back crane has the full load, gently set the crane back on its wheels

Don’t forget to have a plan to remove the rigging from the boom. It will end up high in the air.

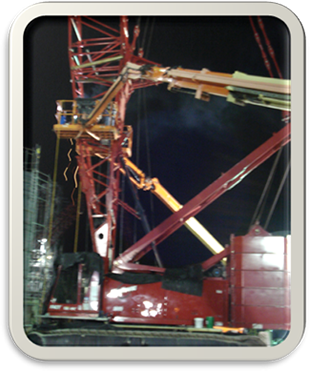

CRANE RESCUE

Be advised not to attempt a crane rescue without the assistance of the crane manufacturer or a registered professional engineer. Often, we find the crane boom or jib badly damaged. Many of these can be saved. However, this is an extremely hazardous procedure. Consult the crane manufacturer or a registered professional engineer

Do not attempt to attach an assist crane to hold the damaged boom.

Doing so will result in disaster.

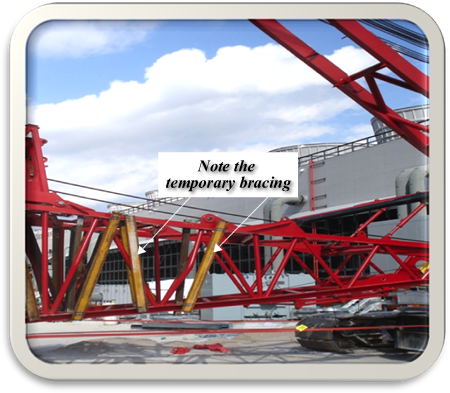

Temporary Bracing to reinforce the buckled boom base section.

IN CONCLUSION

No one plans to have a crane accident. However, you should make a plan for managing one if it should occur.

Key items to include in your plan:

- Know and Post the Emergency Response Numbers

- Assign someone the responsibility for assessing the danger and assisting the Emergency Response Teams

- Know and Post the Crane Manufacturer’s Numbers

- Contact the Insurance Company immediately

- Assign someone the responsibility for addressing the Press

- Secure the site and care for any injured

- Don’t move anything unless to care for the injured

- Take pictures and measurements

- Interview all witnesses

- Have the Crane Manufacturer or Dealer down load the computer

- Effect the clean up using sound engineering practices

Joe Collins, Becht’s Heavy Lift and Heavy Haul SME and his Heavy Lift Team have supported over 25 crane incident investigations around the world. They have safely provided crane recovery services on most of them. In addition, we have provided expert witness services for over a dozen legal cases.

We are ready to assist should the unthinkable happen.

Have a question or would like more information? You may post to this blog or click the link below for more help.