How to Resolve an Engineering Manager’s Typical Dilemma – “Where to Start”

The Problem

Too often, the inability to get the required work done correctly, and on-time, has been blamed on too few people, not enough of the right people, or situations that were not anticipated. Dr. Louis T. Rader’s comments, about engineering management, are still applicable to many managers today. In 1964, he noted that: “The apparent shortages of engineering talent actually can be traced to a shortage of effective engineering management. A poor manager wastes engineering talent. When jobs are well planned and directed, and the work is rigidly oriented to a realistic budget, the professional dignity and capabilities of each engineer working in such an environment are markedly enhanced (Ref. 1). It is amazing that after 55 years, this situation is still pervasive.

However, good leadership is frequently attributed to the person who takes charge and takes immediate action to get the job done. Without proper planning, this often results in solving the perceived problem or the wrong problem rather than the real problem. More productive results can be accomplished if managers would be less concerned with getting something done now and focus more on how best to achieve the desired results.

Discussion

For example, how often have you been part of a project that is well underway, or (heaven forbid), near or at completion when it is discovered that:

- A key element in accomplishing the project’s goals is missing or has been overlooked;

- The project cannot achieve the desired objectives because the wrong problem is being solved;

- Another organization within the company is working on a different project that is trying to accomplish the same objectives as your project or will obviate the need for your project.

Why does this happen? It frequently occurs due to a combination of the following reasons:

- Managers/Supervisors, when faced with tight budget/schedule constraints do not want to expend resources on seemingly needless activities like planning when a solution is obvious;

- They really are not aware of all of the activities and resources required generally because they have never done it before;

- The real problem has not been defined, but rather only the perceived problem;

- They want to impress the boss by getting the problem solved or project accomplished ASAP;

- They do not want to relinquish control of the project for parochial reasons.

Most technically oriented, multi-discipline companies are constantly faced with the need to develop and control complex, labor-intensive projects. This too frequently results in the project not accomplishing the desired goals or being completed late and/or over budget. In the current business climate, the need to be efficient and cost effective has never been more necessary. No longer can companies tolerate inefficiencies to exist solely because “that’s the way it’s always been.”

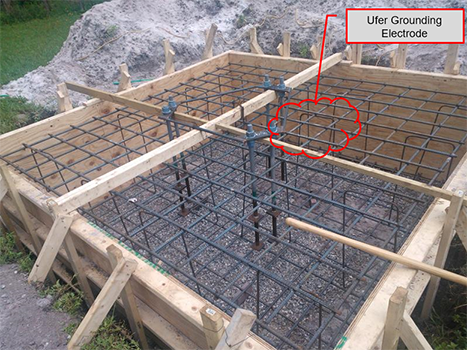

An Effective Solution: The remainder of this article outlines some specific ideas, concepts, and suggestions that have been proven to result in more effective project management and efficient resource utilization, without requiring a vast commitment of resources to the planning process. The following process has been successfully applied on a wide variety of nuclear and fossil-fueled power plant projects and programs including power plant simulator development; large scale asbestos removal; nuclear power plant de-fueling/decommissioning issues; and a joint Department of Energy (DOE)/utility venture. An extremely notable success of the process was in the development and implementation from ground zero to a full-compliance 10CFR50.49 Equipment Qualification (EQ) Program in less than one (1) year for a project that originally was anticipated to take three to five years to finish. (Ref. 2) Although developed for power plant projects, the same process can be readily applied to process plant projects.

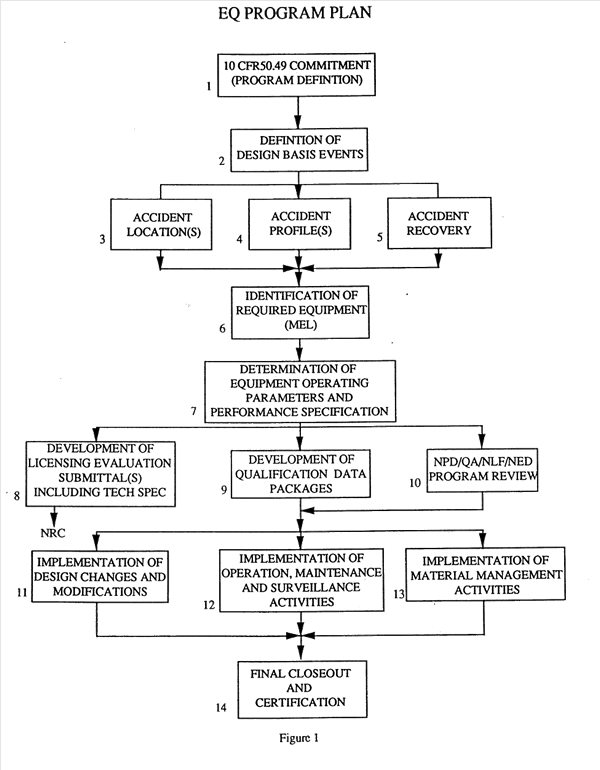

The entire project management process (Action Plan Development Process – APDP) developed and implemented for these projects is too long to describe in this one article. The essential elements of the APDP process is the identification of an appropriate organization coupled with a well-thought-out approach. As part of these elements, there are several key tools involved in Planning and Organizing the work:

- A Work Breakdown Diagram (WBD) (similar to Figure 1);

- A Responsibility Matrix Diagram (RSM); similar to a PMI Responsibility Assignment Matrix (Ref. 3);

- The use of brainstorming techniques to develop the diagrams and clearly define the scope of work and approach involved.

The WBD (Fig. 1) represents the major work activities involved in the EQ Program. This WBD is not intended to replace detailed integrated schedules using such techniques as PERT, CPM, GANTT, etc. Rather, the WBD is intended to complement these techniques by clearly depicting the major activities involved and their interrelationships, as well as to be the starting point for the development of the appropriate integrated and detailed schedules.

The RSM represents the matrix organization to be utilized for the project. The overall purpose of the RSM is to provide a single source for all parties to clearly understand who has the lead and support responsibilities for each block of activities.

The use of brainstorming techniques has proven to be very effective in the development of these diagrams and attaining the mutual agreement of the problem definition, approach and scope. Experience has shown that it has been possible to develop the initial set of WBD and RSM diagrams with less than eight (8) hours involvement with the various technical, management and scheduling personnel involved. The projects where this process has been used involve tens of thousands of manhours, multi-million-dollar budgets, and, whose period of performance is weeks or several years.

Once the WBD and RSM are generated via the brainstorming session, the activities or “blocks” of the WBD can be further defined, if needed. The key to success is the understanding (by the key individuals involved) of the activities and who is involved in each activity.

With the development of the above, an effective core has been created that will allow the remaining elements in project management, (i.e., staffing, directing, leading, and controlling) to be developed and implemented effectively. In addition, when coupled with an overall schedule and cost estimate, a project/program of extreme complexity can be defined on 3-4 pages of material suitable for presentation to higher levels of management for their consideration, if necessary.

At this point, the activities of the WBD can be started in parallel (as appropriate to the WBD). Action now is possible since the parties involved clearly understand the entire project and can proceed, where appropriate, with minimal chance for duplication of effort or performing unnecessary tasks.

The Results

The utility industry is a good example of where more efficient management, especially engineering management, is becoming more and more a necessity to comply with regulatory, shareholder, and corporate issues. Utilities are more frequently using project management processes similar to that outlined here. The result of management implementing this sort of Project Management has the following advantages:

- Identifies either the root cause problem or the process required to identify the root cause;

- Results in a well-defined project/program scope and approach;

- Reduces or eliminates unnecessary or duplication of activities;

- Minimizes possibilities of cost overruns or unexpected ‘missing’ items.

In addition, it:

- Allows utilization of the most qualified personnel available;

- Enhances communication between organizations, especially in the horizontal direction;

- Allows wide flexibility of actual organization and responsibilities;

- Enhances acceptability of the End Product to all organizations that participate in the matrix.

Conclusion

Complex technical problems, with difficult schedule constraints, will always be part of an engineering manager’s life. Management techniques available to address these situations are as varied as the types of organizations involved. The use of the fundamental attributes of any technique, i.e., problem definition, establishment of a completion plan, use of an integrated schedule, and assignment of responsibilities are paramount to the success of any project. However, when faced with these types of situations, innovative approaches that depart from “the way we’ve always done it” should be considered. Utilization of some of the above concepts will allow cost effective preparation of a plan of action, that can be well executed; thereby eliminating the need to choose between Action versus Planning.

Who knows, if you utilize the above techniques, you may never hear again:

“We never have the time or money to do it right, but we always have the time and money to do it over.”

References

- “Engineers Should Expand Their Fields,” Mechanical Engineering, November, 1964.

- “Effective Management Technique to Control Environmental Qualification Program Implementation,” M.C. Annon, M.E. Niehoff, ISA Instrumentation In The Power Industry-Volume 31, May 1988.

- PMBOK® Guide – Sixth Edition (2017) “A Guide to the Project Management Body of Knowledge (PMBOK® Guide)”

Like this blog or

Have a question about Becht’s work in any of their service lines? Please click the link below: