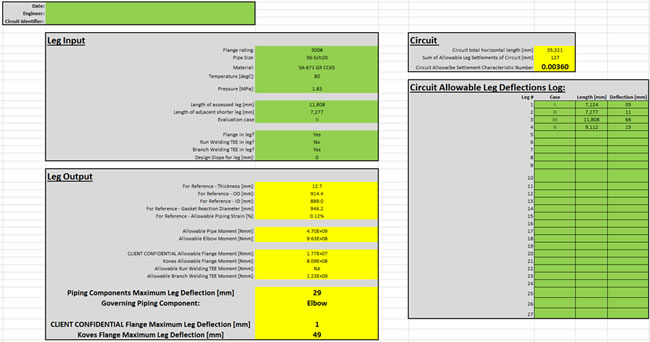

Piping Settlement Screening Tool

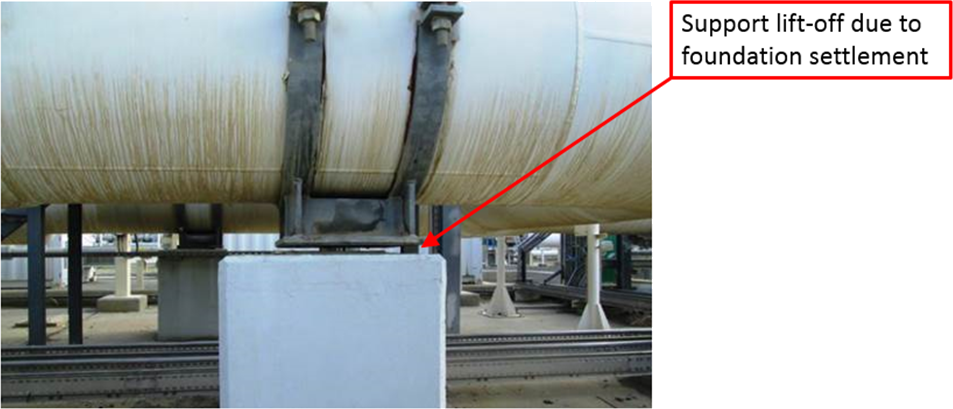

Settlement of a pipe support foundation is usually not a big deal to assess. A local piping flexibility model will reveal if the settled support keeps the pipe bending stresses within the allowable codes and, if the bending stresses are unacceptable, modifying the support and monitor periodically for further settlement is normally a quite manageable task. However, if settlement is occurring site-wide at a large site due to errors in the pre-construction soil surveys, the problem quickly becomes unmanageable. A client recently approached Becht Engineering with a request to develop a screening tool. A tool that inspectors at such a site can easily use in the field to quickly screen pipe circuits subjected to support settlement. The stated objective was to determine which circuits are acceptable without further study based on conservative criteria requiring detailed follow-up, i.e. piping flexibility analysis. This blog supplies an overview of the bases for this tool.

Tool Features

Differential settlement can have an impact on a piping circuit in a number of modes. The listing below shows these modes, including two which are not addressed with the developed tool:

- Excessive bending stress may cause cracking of pipe and fittings.

- Flanges may leak.

- Elbows or TEEs may collapse.

- Rotating Equipment Nozzles – rotating machinery is sensitive to even small amounts of deformation and are excluded from this scope.

- Vessel nozzles – experience shows that a significant amount of deformation of a vessel nozzle due to bending can be tolerated without causing cracking or collapse of the vessel wall. The screening tool need therefore did not consider vessel nozzles.

The approach taken in the development of the Becht screening tool is to determine the allowable moment for each component of a piping leg, select the lowest allowable moment and compare it with the estimated leg moment.

Allowable Moments

Each of the components typically found in a piping system needs to be included.

- Straight pipe – Use a curvature based buckling criterion selected from the text book “Piping and Pipeline engineering” by George Antaki (Chief Nuclear Engineer of Becht Engineering). This criterion is in use in subsea pipeline laying operations. It imposes a limit on the plastic strain in the pipe from which a bending moment can be calculated.

- Elbows – apply a geometry-dependent multiplier on the allowable pipe moment using method published in Teschniche Mechanik, “Load Bearing Capacity of Thin Shell Structures Made of Elastoplastic Material by Direct Methods” by Tran et al. This multiplier method was developed from a series of elastic-plastic Finite Element Analysis (FEA) simulations.

- TEEs – use elbow moment results and apply Sustained Stress Index (SSI) published by ASME, “PVP2014-28267 Sustained Stress Indices (SSI) in the B31.3 2010 Edition” by Paulin et al. Simplified, the SSI can be said to be to collapse what Stress Intensification Factor (SIF) is to fatigue.

- Flanges – use allowable flange moment from the Koves’ method published by ASME, “Analysis of Flange Joints under External Loads”, W.J. Koves. The Client also asked to include their own internal assessment procedure for allowable flange moment. Select the highest allowable moment to be governing.

Estimated Leg Moments

A simple way of assessing pipe moments without a full flexibility analysis is to use the so-called guided cantilever method, developed by Kellogg. This method uses a simple procedure to determine the bending moment in each leg of a pipe circuit. In particular, a rotation correction factor is determined for each turn in the circuit, which is applied as a multiplier on the allowable moments and results in higher allowables than if regular fixed-end conditions were assumed. Three evaluation cases account for the different configurations that can occur in a circuit, where the evaluated leg may be connected to an in-plane or out-of-plane leg of either longer or shorter length than the evaluated leg. Note that for the purposes of settlement analysis, pipe legs oriented vertically need not be considered. The output is a maximum allowable vertical displacement for each leg which can be compared against actual support settlements in the field. Any circuit containing legs that do not pass should be considered for piping flexibility analysis or support adjustment.

Characteristic Number

A dimensionless number for each assessed circuit can be calculated with the tool where the total allowable leg displacements is divided by the length of the circuit. This number can aid in screening out circuits of similar size and containing similar components based on a few field measurement rather than performing the full assessment for every leg. This is particularly useful at sites with wide-spread settlement problems.

Feedback

The Client for which the tool was developed reported back that they were able to screen about 10 circuits per hour, compared with one circuit per day using full-blown piping flexibility analysis.

Below is an example of the input/output screen of the developed tool. The only inputs are the geometric features and applicable components of the pipe circuit. Much of the input is conveniently selected from drop-down menus. By taking the time to develop a practical simplified screening rule based on basic principles rather than brute forcing the problem with vast numbers of detailed piping analyses, a very large amount of time (and money) was saved.

Have a question or would like more information? You may post to this blog or click the link below for more help.

or Call Magnus Gustafsson at

(703) 459-9012