Post-Fukushima: The Concept of Beyond Design Basis Earthquakes

Immediately following the Fukushima accident of March 11, 2011, the US Nuclear Regulatory Commission assembled a Near-Term Task Force to gather the lessons learned from the Fukushima Dai-Ichi accident. The Task Force compiled a set of “Recommendations for Enhancing Reactor Safety in the 21st Century.” The Recommendations were approved by the Commissioner and issued for implementation, with priorities.

In the case of Fukushima Dai-Ichi, the tsunami which was caused by the Magnitude 8.8 earthquake was larger than what the plant was designed for. The tsunami waters crashed over the flood wall and flooded the emergency power supply. At that point, the plant had lost power from offsite transmission lines (a common occurrence when a large earthquake occurs), but had also lost its emergency power generators. This resulted in what is called a Station Blackout. The operators could no longer run the pumps that circulate water to cool the reactor core which was still heating from the residual heat released after the reactor is shutdown. The fuel melted which released hydrogen, which in turn caused a hydrogen explosion.

The important lesson learned from this accident is the need to explore what is now called beyond-design basis events or BDBEs. The concept of BDBE is to ask ourselves: what would happen if an earthquake (or a flood) larger than the design-basis earthquake (or flood) was to occur? The nuclear power industry, in the context of the US NRC orders, rules, and notices, undertook several actions, including: Providing alternate portable emergency power supplies stored on-site and off-site; providing alternate water sources to cool the core; providing hardened vents to vent explosive gases that may accumulate; re-evaluating and improving emergency response procedures.

In the area of the seismic design and the retrofit of Structures, Systems, and Components (SSCs), three considerations guided the industry’s actions:

- First, and preceding Fukushima, the geologists and seismologists were addressing an important question: The study of seismic records from earthquakes in central and eastern US had consistently indicated that they are different from the western US earthquake which had been at the basis of the ground motions used across the US nuclear industry. The central and eastern US earthquakes have a higher frequency content, in other words, they are shorter, more impulse-like. Instead of peaking at 5-10 Hz, the ground motions recorded peaked at 30-50 Hz. This matter was being addressed through NRC Generic Issue GI-199 when Fukushima occurred.

- A second important point, not often mentioned, is that on March 11, 2011 the SSCs fared well during the earthquake shaking. The current seismic design rules in ASME B31.1, ASME III, ASCE-4, AISC N-690, ACI-349, and IEEE-344 (and their Japanese equivalent) do a good job of protecting against the inertial effects caused by shaking. A good example is Onagawa, nearer the epicenter than Fukushima Dai-Ichi, but which did not lose emergency power, and whose three units were safely shutdown with little damage to SSCs.

- The third point is to decide what methods and criteria to use to evaluate the vulnerability of nuclear power plant SSCs to beyond design basis earthquakes?

Let’s take a moment to look at this third point: How to evaluate the seismic adequacy of SSCs against BDBEs?

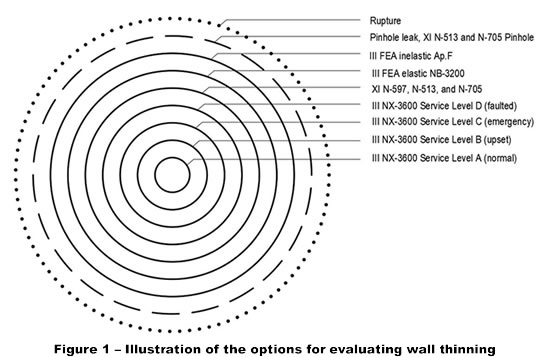

There are basically five options:

Deterministic Stress or Strain Analysis: Here we model the SSC, apply a BDBE seismic forcing function which is a multiple of the design basis earthquake, obtain stresses, strains, loads, movements, and compare them to allowable limits. These allowable limits could be either current design limits or higher limits that would still maintain the SSCs function. Another deterministic method could be based on fracture mechanics analysis: Here, we would postulate a series of cracks, and determine their stability in case of BDBE.

Probabilistic Analysis: In this case, the BDBE seismic input is not a multiple of the design basis earthquake, but a series of potential earthquakes each with its probability: Small earthquakes with high probability all the way to large earthquakes with low probability. This suite of seismic ground motions is called the Seismic Hazards for a given site. Then, the failure of the SSC would also be probabilistic: It would be a series of curves giving the probability of failure of a given SSC (say a piping system, a steel structure, etc.) as a function of the peak ground acceleration. These probability of failure curves for each SSC are called fragilities. The fragilities would then be combined (convolved) with the hazard curves and entered into a probabilistic risk analysis (PRA). This, the seismic PRA, is the method currently being implemented throughout the nuclear power industry in the US to evaluate existing SSCs for BDBEs, and also performed for new designs, in addition to the deterministic stress analysis for design basis earthquakes (NRC Staff Guidance DC/COL ISG-020, “Interim Staff Guidance on Implementation of a Probabilistic Risk Assessment-Based Seismic Margin Analysis for New Reactors,” March 22, 2010, and Regulatory Guide 1.200, “An Approach for Determining the Technical Adequacy of Probabilistic Risk Assessment Results for Risk-Informed Activities.”)

Energy Method: At this time, this approach is still in the conceptual stage as a design tool, but is used to assess an earthquake that has actually occurred (Electric Power Research Institute, “Guidelines for Nuclear Plant Response to an Earthquake”, October 2013). It consists in calculating the energy or the impulse of the BDBE and from there estimating its potential to damage certain types of SSCs. One concept that is being investigated is to correlate damage to the Cumulative Absolute Velocity (CAV) of the seismic time-history (the absolute integral of the acceleration-time signal).

Earthquake-Experience Methods: These methods are based on check-lists of key attributes for each class of SSC which are based on damage data from actual earthquakes or shake table tests. It is a method used primarily as a screening tool to identify the weakest SSCs which would then be evaluated by other methods (Seismic Qualification Utilities Group (SQUG) “Generic Implementation Procedure (GIP)”; and EPRI Report 3002000704, “Seismic Evaluation Guidance Augmented Approach for the Resolution of Fukushima Near-Term Task Force Recommendation 2.1 – Seismic”, 2013).

Testing: Because of costs, testing has been focused on two types of SSCs: (a) SSCs that must perform an active function that would be practically impossible to qualify by analysis (for example electrical components, pump operation, etc.), and (b) as a means to obtain data to benchmark the analysis methods and criteria for SSCs such as piping systems, steel structures, cable trays, etc.).

In Summary

The Fukushima Dai-Ichi accident has triggered a large effort within the nuclear power industry to evaluate and remediate the vulnerabilities of nuclear power plants to beyond design basis events (BDBE). Improvements in several areas, including redundant emergency power supplies, flood protection, emergency response, hydrogen venting, are underway.

The accident, together with earlier questions related to the central-eastern US seismicity, has caused US nuclear power plants to investigate BDBEs using seismic probabilistic risk analysis (SPRA).

The same earthquake also indicated that seismic shaking alone, excluding the tsunamic flooding, did little damage to SSCs, which supports the adequacy of the seismic design rules of the current codes for inertia effects.

Have a question or would like more information? You may post to this blog or click the link below for more help.

[readon2 url=”index.php?option=com_rsform&view=rsform&formId=4&Itemid=739&lang=en”]Request Info[/readon2]