Reducing Loss of Primary Containment (LOPC’s) in a Refinery

Reducing Loss of Primary Containment (LOPC’s) or commonly referred to as “leaks” in a refinery is a key factor to improve reliability. Historically, most refiners reduced the high consequence leaks to avoid major incidents; however, lower consequence related leaks were not given high priority. Today high reliability is required, and reduction of all leaks is desired due to greater legal and regulatory oversight of the industry. Approximately 90% of the leaks occur in piping systems. These leaks typically fall into 3 categories; internal corrosion, flange leaks and external corrosion. Many refiners have programs in place for internal corrosion and programs for flanged joints; however, many lack comprehensive programs for external corrosion. To fully reduce LOPCs a comprehensive internal and external corrosion management system is necessary.

Background

Many refineries have had Mechanical Integrity related audits performed during the last decade. These audits have found many areas for improvements and programs were initiated to address the short comings found by the audits. Based on these audit findings many companies launched corrosion management programs centering around the development of Corrosion Control Documents (CCDs), which addressed many of the known internal damage mechanisms. Many refineries also initiated Risk Based Inspection (RBI) programs which resulted in inspection plan development as well as risk-based inspection intervals. These efforts primarily addressed internal damage mechanisms. The external damage mechanisms were typically not effectively addressed by CCDs and RBI and many sites continue to have numerous leaks due to external damage mechanisms, leading to poor overall performance.

LOPC Analysis

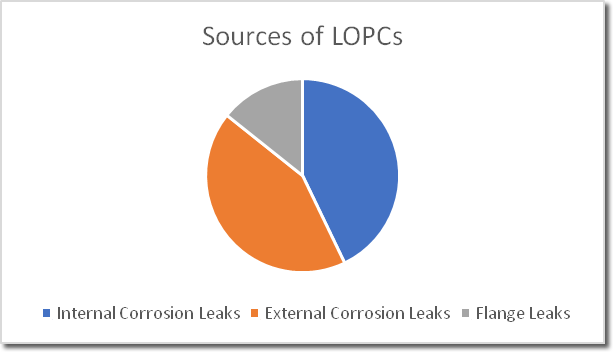

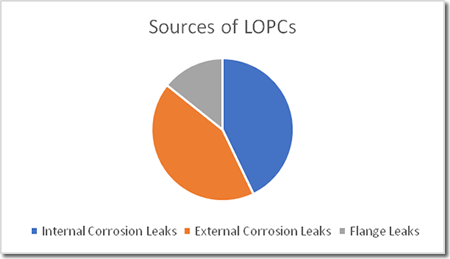

A LOPC analysis was performed at several large refineries. The analysis reviewed a decade of leak data for all levels of risk. The approximate results of the analysis are shown in the chart below:

The analysis showed that over 90% of the leaks occurred in piping systems and external corrosion accounted for 40%-50%, internal corrosion 40%-50% and flange leaks approximately 15% of the leaks.

The primary external damage mechanisms that causes leaks are listed below:

- Corrosion under insulation (CUI).

- Underground piping and Soil-to-Air interface.

- Touch-point corrosion.

- Dummy leg corrosion.

- Deadleg corrosion (this may be internal).

- Small bore piping (vibration)

Many times, leaks resulting from external damage mechanisms are of low consequence such as leaks occurring in OSBL piping, but sometimes an external damage mechanism related leak results in significant reliability and/or environmental and regulatory impact. Leaks caused by these external damage mechanisms may initially be considered low risk; however, over time, the risk may increase if there is not an effective inspection program in place to mitigate these external damage mechanisms.

Becht Engineering Can Help

Becht Engineering offers a complete Fixed Equipment Mechanical Integrity program. The program includes CCD and RBI development as well as programs for all the external damage mechanisms. This program can work in any IDMS environment.

Have a question or would like more information? You may post to this blog (below) or click the link below for more help.