Restoring High Energy Piping System Performance by Reducing Friction

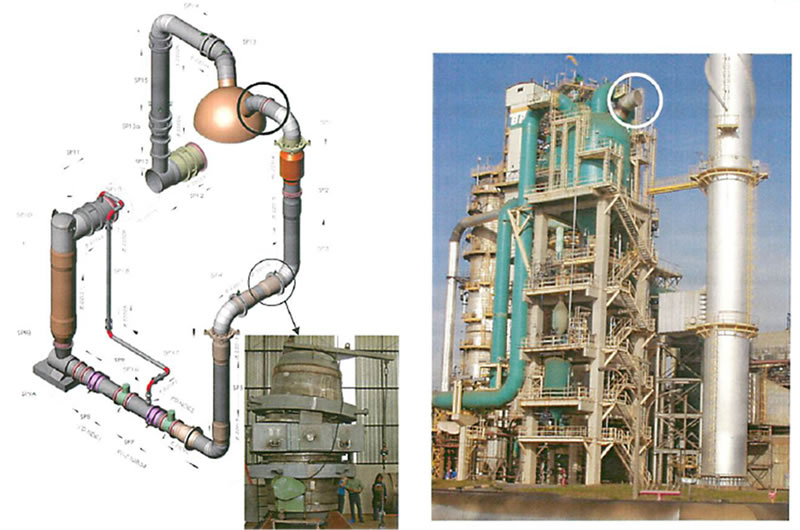

“When You’re Stuck, You’re Stuck” Over years of normal operation – like cycling and wear and tear – High Energy Pipe support friction can increase causing distress in these critical systems. Friction is a common phenomenon which is widely understood and considered in both piping analysis and support design. Generally, a piping analyst models a […]