Evaluation of Corroded Pipe in Accordance with ASME B&PV Code Section XI – A Comparison of the Three Code Cases

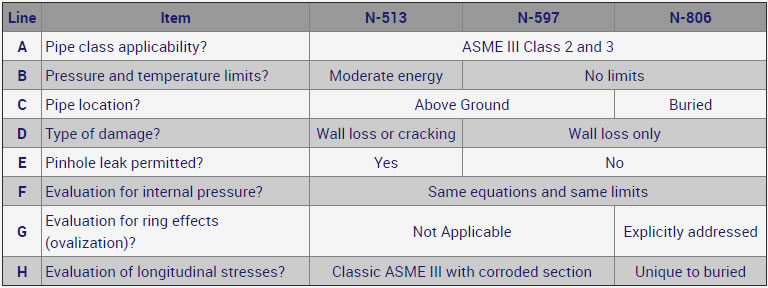

The evaluation of wall thinning corrosion in steel pipes is addressed in three ASME XI code cases: N-513, N-597, and N-806. I have no ambition here other than to summarize in a table the differences between these three code cases. A brief commentary follows the table. The brief commentary… Line A – While these are […]