Optimizing Coker to a True Limit for Safe Crude Rate Increase

Situation: Client crude rate was limited due to fouling in the roof tube section of one of the Coker furnaces.

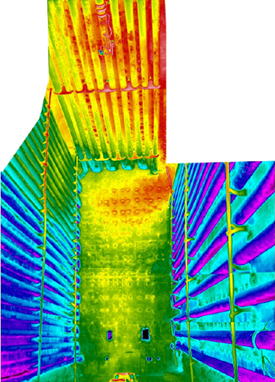

Action: Becht Fired Heater Services IR technicians mobilized to site 3 days faster than the company that routinely scans these furnaces. Becht analysis of the IR data aided in understanding tube mid-wall temperatures to consistently run to a tube metal temperature limit on this heater. This allowed increased throughput.

Action: Becht Fired Heater Services IR technicians mobilized to site 3 days faster than the company that routinely scans these furnaces. Becht analysis of the IR data aided in understanding tube mid-wall temperatures to consistently run to a tube metal temperature limit on this heater. This allowed increased throughput.

Result: These actions allowed the plant to increase crude rate 1,000/bpd to minimize LPO event. The improved temperature data aided in optimizing the Coker heater and capturing increased crude rate another 3 months – until a planned de-coke window.

Lesson Learned: Expedited and significantly improved data set provides needed analysis for safe crude rate increase.

Contact