IPP Combined Cycle Risk Assessment

Situation: A large 300 MW Combined Cycle Generating Plant was experiencing an increasing frequency of forced generation outages due to Balance-of-Plant equipment reliability resulting in significant lost revenue. The Plant Operator was unable to identify a single-cause or reason for this increasing forced outage trend.

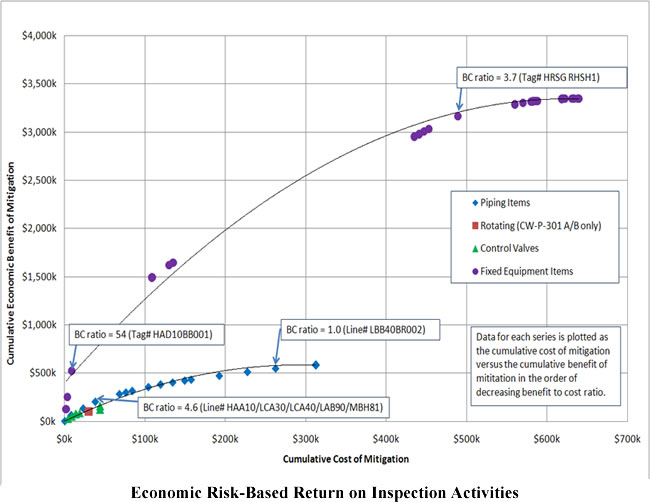

Action: Using its Risk-Based Equipment Reliability Planning Process, Becht developed an Inspection and Maintenance Plan for:

- All plant fixed equipment (72 items assessed)

- Main process piping (94 piping lines assessed)

- All rotating equipment (31 items assessed)

- Critical control valves (9 items assessed)

Becht’s work process was compliant with API RP 580, Risk-Based Inspection and ASME PCC-3-2007 Inspection Planning Using Risk-Based Methods. The process included data collection, site visits, review of operating and design conditions, historical operating information and data analysis.

Results: Becht identified unmitigated economic risks (lost revenue), mitigation costs and performed a cost/benefit analysis which identified $4,410,000 in lost revenue that could be accomplished via a $927,000 investment in additional inspection and maintenance tasks.

Contact