Deferring Turnaround Work Without Increasing Risk

By Clayton Smith and Gordon Lawrence

In this article we will discuss the issues around deferring or postponing some, or all, of the work intended for an upcoming maintenance turnaround to a future date. We will look at the reasons why one might wish to defer work and examine the risks involved in deferring work. Finally, we will share a practical and effective method for deciding whether scope items can be deferred.

What is a maintenance turnaround?

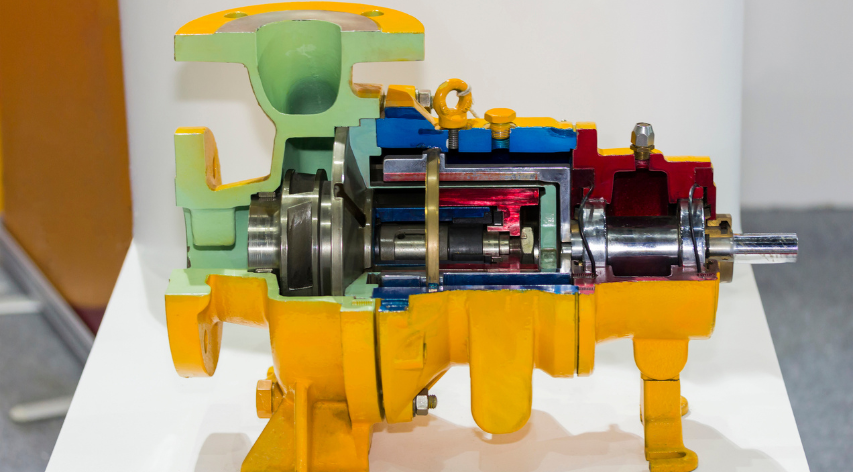

Maintenance turnarounds (sometimes called shutdowns or outages) are necessary events in the long-term operation of any facility that uses large equipment and machinery in a continuous production process. Equipment may be subject to regulatory inspection to confirm that it remains safe to operate, and it may require repairs or cleaning. If the process runs continuously, then much of this equipment may only be accessible when the plant is shut down.

If a plant shutdown occurs, it is not producing product and there is consequently a lost production opportunity. Hence the plant needs to be “turned around” and restarted as quickly as possible.

In addition, doing all this inspection and maintenance work costs money. Doing it quickly, in order to keep the turnaround time to a minimum, costs even more money. As a result, plant management generally wants to focus on finding the optimum amount of work to balance keeping the scope small against ensuring the plant will be safe to start up and run, and that the risk of an unplanned breakdown is acceptably low.

Why defer maintenance turnaround work?

There are three main reasons to defer turnaround work. (Strictly speaking, the correct term would be “postpone,” since the work is being postponed to a definite future date rather than deferred to an indefinite future date.)

- Postponing the entire turnaround to a future date a few weeks or months in the future, because the current market for the site’s product is “hot” and it wishes to produce as much as possible while the favorable opportunity lasts, in order to sell at a high price.

- Postponing elements of the scope to a future turnaround to reduce the scope of the current turnaround because of budget constraints.

- Postponing the entire turnaround to a future date one or more years in the future, because the site wishes to extend the turnaround intervals as a change to the long-term plan and to better optimize production uptime.

We will concern ourselves here with the first two of those three reasons. The third reason, that of wishing to extend the turnaround interval, is a whole separate topic and will be covered in a future article.

Issues and risks involved in deferring turnaround work

There are several obvious issues and risks in deferring or postponing work to a later turnaround event:

- For statutory inspection work, discussion and negotiation with the regulatory authorities is needed to determine what is acceptable in terms of alternative, non-intrusive inspection and/or to agree on a safe extension of the inspection interval.

- For corrective maintenance, discussion is required as to whether it is acceptable to continue to run with the faulty equipment for a longer period.

- For preventive maintenance work, the level of acceptable risk must be debated as the risk of equipment failure on the run may increase.

- For cleaning work, data needs to be examined to assess whether the additional loss of function over time is acceptable.

Standard scope challenge with risk-based methods

Many firms currently use a scope challenge methodology for all of their turnarounds to ensure that the optimum scope is included in the turnaround. The better firms use a risk-based methodology that includes a risk-based calculation for preventive maintenance scope items. Such methods are discussed in more detail here.

These methods look at:

- Whether doing the work contributes to the business objective of the turnaround event (i.e., does it need to be done at all?)

- Whether the scope could be done at another time, either on-the-run or during some other outage prior to the turnaround

- Whether the scope could be postponed to some other outage after the turnaround without an unacceptable increase in risk to operational health and safety, or to operational production

- If the scope is required, whether it could be done in a less intrusive manner (e.g., could an inspection be done externally instead of internally? Does an inspection need to be made through every manway, or is it acceptable to open only one?)

- If the scope is preventive in nature, whether the reduced risk of breakdown gained by overhauling the item during an expensive turnaround is worth it, compared to leaving the item alone and taking the risk that it might breakdown on-the-run

Assessing work scope items for deferral

The exact same methodology can be used to assess scope for deferral. The only change will be to the third bullet listed above. In this case, the focus is now specifically on whether the scope item can be postponed to the proposed new turnaround date without an unacceptable increase in risk.

By looking at the work from this point of view, a monitoring or mitigation plan can frequently be implemented that allows the unit to run onward to the postponed turnaround date.

Occasionally, it may be determined that not all scope items can be safely postponed. But even in such a case, the scope size can often be reduced to the point where the main turnaround can still be postponed and only a small “pit-stop” is needed for those scope items that cannot be delayed.

Conclusion

With careful use of risk-based scope challenge methodologies, it is possible to quickly and efficiently assess the feasibility of postponing a turnaround to a more business-favorable date.

Need advice or counsel for deferring your turnaround? Contact a Becht expert regarding your future plans.