Pumping Challenges in Plastics Pyrolysis and Other Contaminated Oil Applications

Plastics pyrolysis is an emerging technology that advances the circular economy by converting non-recyclable plastic waste into valuable hydrocarbon products. Though the environmental opportunity of plastics pyrolysis is a net positive, maintaining the reliability of equipment in this process can present some unique challenges in maintaining equipment reliability.

One of the most recurring difficulties is the handling of residual solids and contaminants within heavy liquid streams such as slop oil.

Common issues: Hot fluid, adhesive residue, and plastic aggregate

Slop oil, the catch-all for heavy liquids, waxes, and residual hydrocarbons in pyrolysis operations, poses unique pumping challenges. Unlike conventional hydrocarbon streams, this material often contains adhesive, paste-like residues and hardened plastic aggregate as well as waxes that settle and accumulate within tanks and lines. These contaminants must be managed through effective operating practices and utilizing suitable pumping technology.

The elevated operating temperature of approximately 300°F (149°C) further complicates the overall system operation, piping design, and pump selection.

Improving piping system design

Becht was engaged by a client experiencing acute operability issues with their slop oil system. What began as a request to help troubleshoot a specific reliability concern ultimately revealed broader system design challenges that were driving the problem.

During the review, Becht noted that the process pumps took suction directly from the bottom of the slop oil vessel without a standpipe. This arrangement guaranteed that contaminants heavier than the oil were being funneled directly into the pump.

Exacerbating the issue, the lack of a standpipe in the vessel meant a concentrated surge of solids entered the pump upon startup, causing high vibration and, in some cases, pump failure. The slop oil vessel would have benefited from both a standpipe and a cleanout manway to mitigate the concentration of contaminants entering the pump.

Incorporating a strainer proved ineffective in removing the contaminates due to the adhesive properties of the residue and the quantity of the plastic aggregate. An attempt was made to utilize a cone-type strainer, which plugged and starved the pump of liquid, leading to a pump failure.

Downstream of the pump, the piping teed into a recycle and the main process line that continued through a control valve and into a receipt vessel. The spillback was intended to keep the solids in the slop oil tank suspended, preventing contaminants from settling out of the fluid. However, the spillback line was twice the size of the pump discharge nozzle and wide open to the slop oil tank with no control valve, causing the centrifugal pump to run outside its acceptable operating window.

The spillback line configuration had to be evaluated to determine the optimal flowrate to keep the contaminants suspended in the slop oil tank. This flowrate is an important input parameter when selecting the appropriate pump hydraulic profile, in that the chosen pump needs to handle both the feed forward and the recycle flow while operating at the elevated temperature.

Because the piping configuration with the recycle line introduces another level of complexity, the design requires greater attention to pipe stress to allow for stresses at both ambient and operating temperatures. Small, low-duty pumps such as these will be more likely to experience pipe strain that can be transferred into the pump’s internal parts, further reducing the pump lifecycle.

API 686 provides guidance for pipe alignment and pipe strain inspection. ASME B31.3, MSS-SP-58, and MSS-SP-69 provide some guidance for pipe supports in elevated temperature applications, but this can be difficult to glean and will require a piping subject matter expert to help define the right installation expectations.

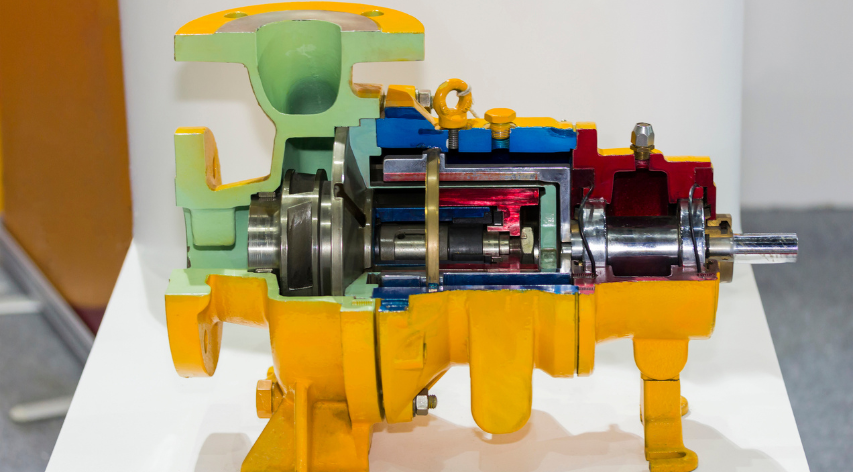

Comparing pump types

A magnetic-drive centrifugal pump was installed in this service to eliminate the need for a mechanical seal and all the maintenance and operating attention associated with it. While these pumps offer leak-free operation, they are highly intolerant of contaminants due to narrow internal passageways and non-mechanical power transfer of the magnets. Additionally, a standard centrifugal impeller is prone to high vibration when the adhesive residue collects in the passageways. As a result, the client was unable to operate these pumps more than one to two days at a time without invasive repair work.

Since strainers were not practical, the team focused on selecting an alternative pump design for the application. Becht always encourages open dialog with the manufacturer’s applications engineer to evaluate operating conditions and intent, and to discern the values and weaknesses of each solution. In this case, the options considered were:

- Traditional ANSI process pumps – With an appropriate seal support system (API Plan 14/65) and attention to selecting a solids-handling impeller design, this option offers a balance between maintainability and robustness. The addition of coatings to the pump internals may also prevent or mitigate the risk of imbalance caused by the adhesive residue.

- Canned motor pumps – These use typical centrifugal process pump impellers but offer an option for injecting a clean flush stream (API 685 Plan 32-S) to prevent damage to the motor and product lubricated bearings. While these pumps can mitigate contamination issues, they add complexity and cost, due partially to the fact that repair is not typically performed by facility maintenance staff. Applied and designed correctly, these are very reliable pumps.

- Engineered diaphragm pumps – These are a temperature-limited solution with concerns over the diaphragm material and check valve fouling due to the solids. While attractive in principle, the adhesive nature of the solids and the elevated temperatures may compromise their reliability.

- Rotary lobe pumps – More common in clean viscous service, the mechanical seals in these pumps are sensitive to certain forms of contamination and would likely experience premature seal failure. These pumps are relatively inexpensive and easy to repair, but they would not be ideal for this application due to probable issues with the seals.

Recommending a path forward

Before proceeding with any replacement, further process engineering was essential for determining whether a new pump hydraulic profile would be required to maintain solid suspension in the slop oil tank with the recycle line. In this case, the required process flowrate downstream is only 5-10 gpm, potentially allowing batch processing at a far lower flowrate.

Dedicating some time to further analyzing the application drew attention away from solving the perceived pump problem and instead identifying an innovative, out-of-the-box solution.

Closing thoughts

Becht continues to support this client (and many others) in improving system performance through vendor discussions, technical evaluations, and, ultimately, defining long-term, reliable solutions.

In every case, it is important to think beyond the pump itself. There has been much conversation around adhesive residue and its effects on equipment – but what about all the piping and control valve trim? A truly effective solution should also consider system life expectancy and the maintenance practices required to meet facility production goals.

A final note of caution: when all you have is a hammer, everything looks like a nail. We don’t see things as they are; we see things as we are.

Experiencing your own tough pumping problem? Becht’s experts are ready to help you find a lasting solution. Reach out anytime.

Like what you just read? Join our email list for more expert insights and industry updates.