Core Components of an Effective OEMS in High-Hazard Operations

In Part One of this series, we discussed organizing your business documentation within the framework of an operations excellence management system (OEMS) to provide a foundation for effective control and continuous improvement of your operations. In this second part, we’ll explore the key components needed to establish a strong OEMS in high-hazard industries, where managing risk is first and foremost.

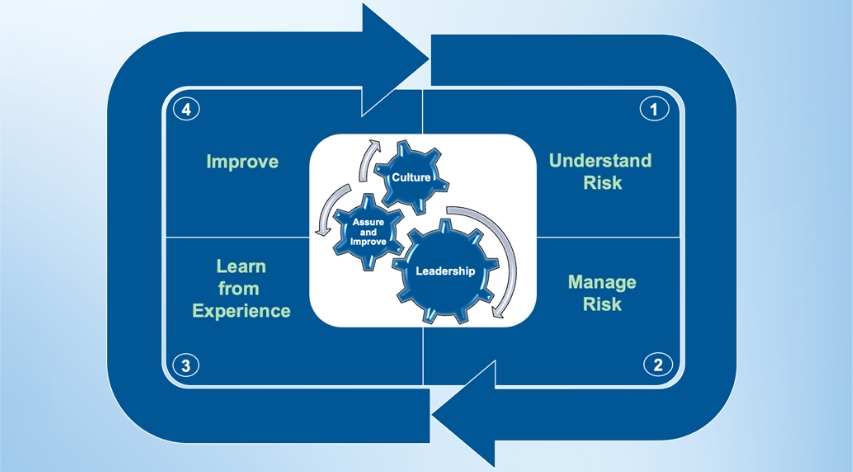

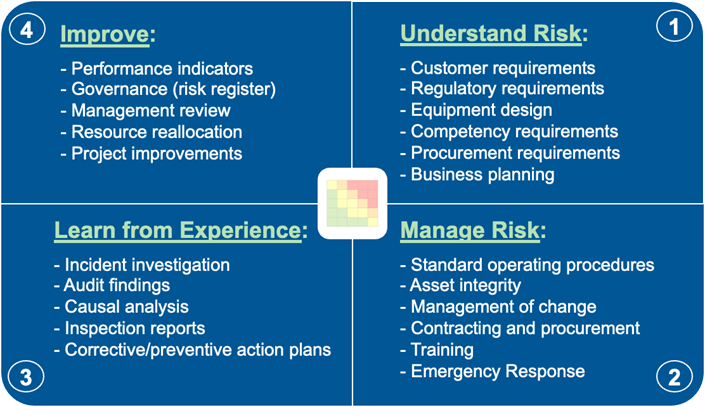

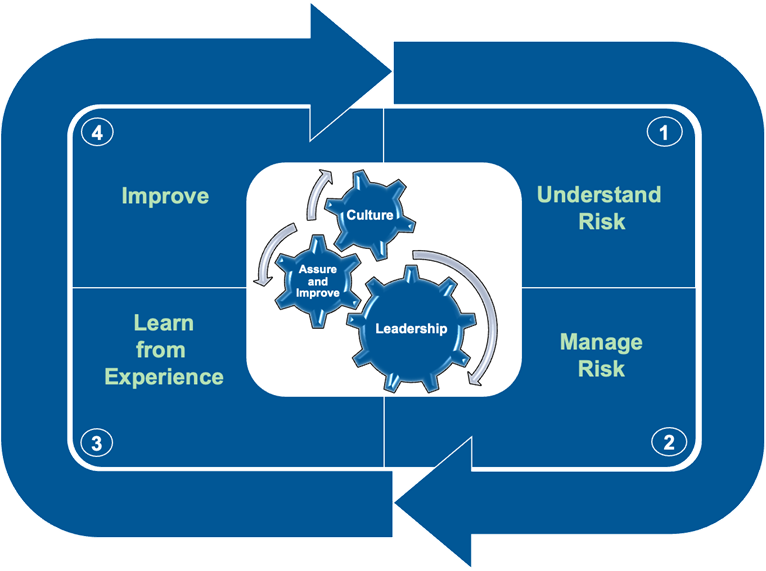

For illustrative purposes, an OEMS framework is like an automobile’s chassis: it’s the platform that supports the motor and body of the car. In the high-hazard manufacturing sector, the “chassis” of an OEMS is well established and consists of four major components: 1) understand risk, 2) manage risk, 3) learn from experience, and 4) implement improvements to reduce risk.

Understand Risk

In this first component, the focus is on identifying and understanding requirements. Industry standards (such as API for oil and ISO 9001 for quality management) are a starting point and can then be tailored to the specific hazards of your operation. Legal and regulatory requirements are clearly identified. Non-negotiable life-saving rules are in place.

Identify what can go wrong before it does. Go beyond regulatory requirements to adopt best practices with frequent hazard analyses like HAZOP or FMEA, regular audits, and a risk register. Accurate and detailed information on chemicals, process technology, and equipment is maintained to identify hazards and understand risks. Multiple safeguards and controls are confirmed in place to prevent major incidents.

Don’t underestimate the importance of identifying key competencies. People are the weakest link. Rigorous, ongoing training – simulations, certifications, drills – ensures people know their stuff. Pair that with competency assessments: don’t assume someone’s good – prove it.

Manage Risk

Implement ironclad procedures for every critical task (e.g., how to start a reactor or handle a chemical spill). No ambiguity. Everyone follows the same playbook, every time. Equipment fails – it’s a question of when, not if. A proactive schedule for maintenance, inspection, repairs, and replacements, backed by predictive tools like vibration analysis or thermal imaging, keeps breakdowns from turning into catastrophes.

High-hazard industries evaluate and control changes in process conditions, technology, equipment, procedures, and personnel. Assurances are required to safely start or restart after shutdown or idling. Capital projects are integrated safely into current operations. High-hazard industries also rely heavily on contractors. This requires robust systems to ensure contractors are qualified and adhere to safety and quality standards when working on process-related activities.

Emergency response plans are well-defined, tested rigorously, and updated regularly. Transparent communication with external stakeholders ensures preparedness beyond company boundaries. Rapid-response teams are trained to handle unexpected safety incidents effectively.

Learn from Experience

When something goes wrong, dig deep: identify nonconformances, determine causes, and apply corrective/preventive actions. Small leaks and near misses get tracked and fixed fast. Avoid blame and apply human performance principles, making it hard to get things wrong and easy to get things right. Embed the lessons learned across the organization and the industry.

OEMS audits are a key component of corporate governance and a great opportunity to learn. They confirm the effectiveness of operational risk controls and verify compliance with legal/regulatory requirements, company policies, and standards of operation. Audits reduce operational risk by proactively identifying and correcting weaknesses in the OEMS design and implementation.

Improve

Start with defined performance metrics, because you can’t improve what you don’t measure. Key indicators like uptime, incident rates, maintenance backlog, or process deviations need to be tracked in real time. Dashboards and measurement systems keep everyone accountable and focused. Benchmark against industry leaders.

Improvement is predicated on strong leadership and oversight. Management reviews are critical to assure OEMS implementation. Update processes and procedures and provide additional training based on risk assessments, audits, incident learnings, and technological advancements.

While the four major activities comprising this OEMS chassis provide the platform, we still need a strong engine in our OEMS. This is where leadership and culture come into play – the motive force propelling the OEMS forward.

Top brass needs to own the management system: funding it, reviewing it, walking the floor, and seeking evidence that risk controls are in place and effective. If leaders treat it as a checkbox activity, the whole framework rots. Leaders allocate resources (financial, people, and organizational) and establish responsibilities and authorities to execute the OEMS and accomplish strategic business goals and objectives. Leaders assure compliance with requirements and continuous improvement of the management system.

Culture eats strategy for breakfast; if people don’t buy in, the management system is dead on arrival. People must understand how to execute a procedure, but, more importantly, they also need to understand why. Skipping a step in a procedure for convenience’s sake is human nature and can often happen with no negative consequence. However, this lack of consequence is often due to additional layers of protection of which the worker may be unaware. Skipping steps will catch up with you. Maintaining a sense of vulnerability and seeking to understand the bigger picture are critical. Workers are encouraged to stop unsafe work without fear of retaliation. A “stop if unsure” policy is a must-have. Everyone actively reports near-misses and safety concerns, knowing they will be acted upon. Safety is discussed regularly and includes feedback loops.

Stagnation kills. It’s not about perfection on day one – it’s about getting better every day. Leaders keep the system moving in the right direction. Becht’s technical advisors have been in your shoes. We know how to help you establish an OEMS that keeps your company moving in the right direction. Let us know how we can support you.

In Part Three of this series, we’ll talk about how to get started implementing an OEMS in a way that integrates with and strengthens your existing business.

Like what you just read? Join our email list for more expert insights and industry updates.