How to Implement an Operations Excellence Management System (OEMS) in High-Hazard Industries

As we discussed in Part One and Part Two of this series, an operations excellence management system (OEMS) that is actively implemented by strong leaders is fundamental to business success. Organizing your business documentation within the framework of an OEMS provides a foundation for effective control and continuous improvement. For existing companies without an OEMS, the best place to start is by creating and implementing a company-specific OEMS standard tailored to the context of your business. This single, high-level document will describe the requirements and structure of your OEMS.

Define the Scope of Your OEMS Standard

The scope of your company’s OEMS standard should include all key aspects of your operation, providing a comprehensive and integrated view of the company’s operating risks. These aspects include:

- Occupational safety

- Health

- Process safety

- Environmental

- Asset integrity

- Reliability

- Physical security

- Cybersecurity

- Business continuity

- Quality assurance

Align with ISO Management Systems via the PDCA Cycle

Many high-hazard companies comply with ISO 9001 (quality), ISO 14001 (environmental), ISO 45001 (occupational health and safety), and other ISO management system standards. The International Organization for Standardization requires all of these “management systems” to follow the PDCA (Plan-Do-Check-Act) approach. It makes sense for your company’s OEMS to do the same.

The PDCA cycle is a concept developed over 60 years ago by a famous business management guru named W. Edwards Deming. Essentially, the PDCA concept says:

- Before you start implementing anything, know which objectives you want to achieve: the Plan phase.

- Once you know what you want to achieve, start implementing your process safety, business continuity, quality procedures, or whatever the business, standard, and regulation is focused on: the Do phase.

- Monitor your system and measure if you achieved your objectives: the Check phase.

- If what you achieved is not what you planned for, or external factors have changed the plan, fill the gap: the Act phase.

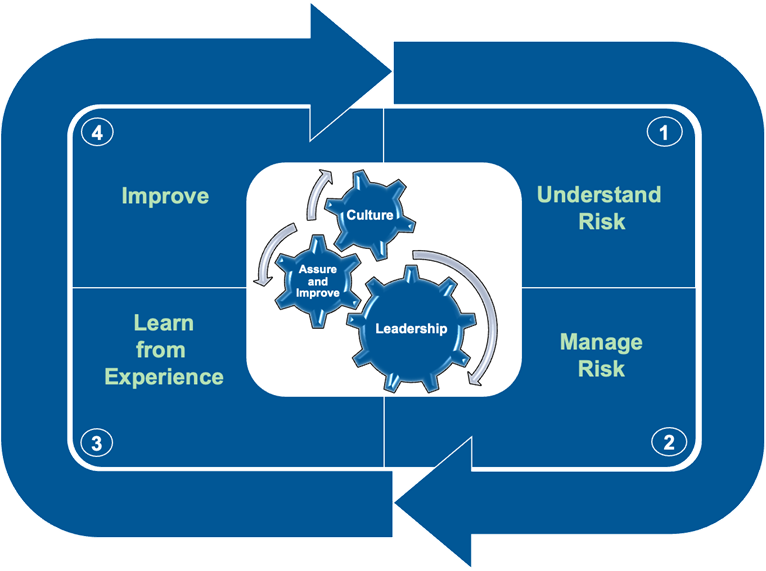

This graphic depicts the OEMS framework we presented in our previous blog aligned with this PDCA cycle of continuous improvement:

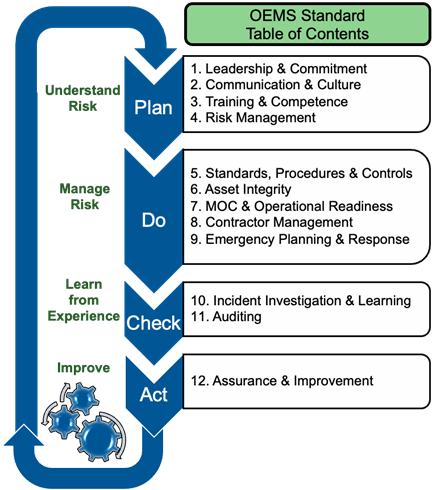

Organize Your OEMS into Clear Elements

An OEMS has elements within each of the four PDCA components of risk management. The purpose of these elements is to communicate the structure of the OEMS to various stakeholders (employees, insurers, etc.) and to facilitate navigation within the management system – like a table of contents. The number of elements is not set in stone, but an effective OEMS framework typically contains between 10 and 20. Too few and you don’t adequately convey the PDCA cycle. Too many and you can’t see the forest for the trees.

Many industry associations have defined the elements of an OEMS structure for companies to consider. A couple of examples come to mind:

- International Oil and Gas Producers (IOGP) Report 510 – Operating Management System Framework for Controlling Risk and Delivering High Performance in the Oil and Gas Industry (10 elements)

- Center for Chemical Process Safety (CCPS) Guidelines for Risk-Based Process Safety (20 elements)

Select and Tailor Elements for Your Business

A company should initially decide on the number and scope of these elements (i.e., the table of contents) for their company-specific OEMS standard. Their framework should allow for various topics to fit logically within an element as additional standards of operation are defined over time – an outcome of their continuous improvement activities. This graphic depicts an OEMS standard with 12 elements:

In this example, the requirements to establish KPIs and conduct management reviews are part of Element 12: Assurance and Improvement. Capital project management requirements are defined in Element 7: MOC and Operational Readiness. Requirements for determining organizational structure, goal-setting, and business planning are contained in Element 1: Leadership and Commitment. The specifics of your OEMS may be slightly different, but should still follow the basic stages of Plan-Do-Check-Act.

The elements within the OEMS don’t work solo. They’re a machine: standards guide training, metrics flag risks, investigations feed improvement. Miss one, and the whole structure wobbles – a serious concern in a high-hazard world where even minor wobbles can have significant consequences. The importance of strong leadership and employee buy-in should not be underestimated.

Protect People and Improve Performance with OEMS

To wrap up, implementing an effective operations excellence management system (OEMS) is a fundamental necessity in high-hazard industries. Companies with excellent operating results distinguish themselves through unwavering leadership commitment, a deeply embedded safety culture, and proactive risk management. By learning from both exemplary practices and past incidents, organizations can enhance their OEMS to protect workers, communities, and the environment while achieving measurable business impact.

Looking to establish or enhance your OEMS? Becht’s deep expertise – from high-level frameworks to detailed elements – makes us your ideal partner. Reach out to get started.

Like what you just read? Join our email list for more expert insights and industry updates.