HTHA Risk Resolved Through Global Collaboration

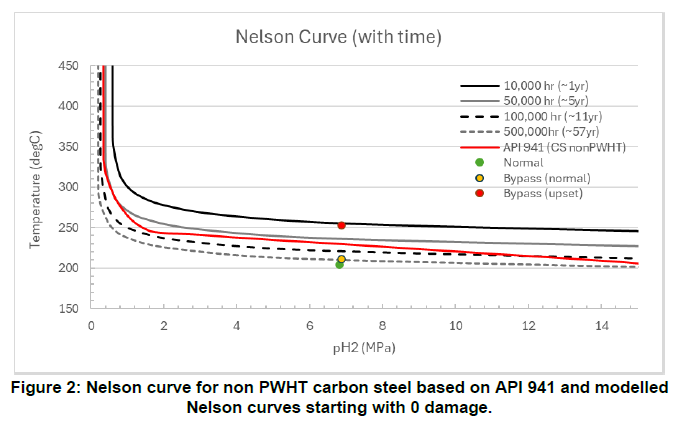

A major refinery faced temporary operating conditions that pushed hydrogen-rich systems beyond their original design temperature limits. This created the potential for accelerated high-temperature hydrogen attack (HTHA) damage in critical equipment. Becht was engaged to analyze the condition, quantify the increased damage rate, and assess the impact on the service life of the affected exchangers.

Objective

Evaluate the temporary increase in HTHA damage rate and determine the impact on equipment life expectancy, enabling safe and reliable operation until permanent replacement could be installed.

Approach

Becht applied its proprietary HTHA quantitative model to estimate the rate of accumulating damage and the remaining service life of the exchangers. Drawing on global expertise, Becht teams across multiple regions worked in sequence, leveraging time zone differences to accelerate the analysis and deliver timely results.

Solution

Within just three days – far faster than typical turnaround times – Becht provided a quantified damage assessment and guidance on safe operating duration under the elevated conditions. The analysis confirmed that the equipment could remain in service until the replacement was available, avoiding unplanned downtime.

Value

By rapidly quantifying risk and providing actionable guidance, Becht enabled the client to:

- Continue operating without an immediate unit shutdown

- Confidently plan equipment replacement on their own schedule

- Reduce analysis turnaround time from weeks to three days through coordinated global collaboration