Improving Pump Reliability in Plastics Pyrolysis Operations

A plastics-to-hydrocarbon producer faced recurring pump failures in its slop oil system. The stream contained adhesive residue and hardened plastic particles, and it operated at elevated temperature. This combination created chronic vibration and repeated shutdowns that drove up maintenance needs.

Understanding the problem

Becht discovered that the pumps were taking suction from the bottom of the slop oil vessel with no standpipe. This arrangement pulled accumulated solids directly into the pump, especially during startup when a concentrated slug of contaminants entered the suction. Attempts to mitigate the issue with a cone strainer caused plugging and flow starvation. Additionally, an oversized and fully open spillback line forced the pump to operate outside its intended window and contributed to pipe stress concerns that further reduced pump life.

Evaluating pump options

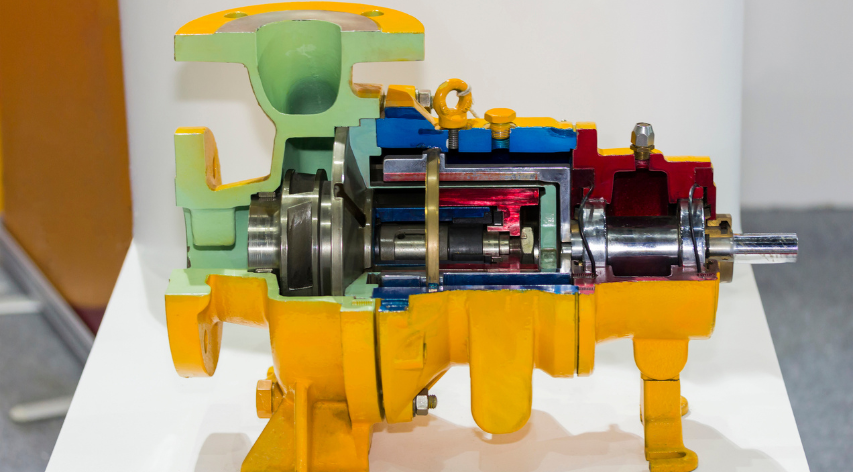

The client had selected a magnetic-drive centrifugal pump to avoid seal issues, but the design’s tight internal clearances made it highly vulnerable to residue. Becht collaborated with the pump manufacturer to identify better-suited options, including:

-

ANSI process pumps with solids handling capability to improve robustness

-

Canned motor pumps with a clean flush stream to protect internal components

-

Engineered diaphragm pumps that could function at lower temperature but were sensitive to fouling

This review highlighted that even the right pump would underperform without system-level changes.

Charting a path forward

Becht reframed the challenge around system behavior rather than equipment replacement. The team evaluated the recycle arrangement to confirm the flow necessary to keep contaminants suspended in the vessel. The downstream requirement was relatively small, which made it possible to consider low-rate batch operation to reduce solids loading. Becht also recommended changes to the vessel design and piping layout to limit startup surges and reduce strain transferred into the pump casing.

Improving long-term reliability

These findings helped the client move away from reactive repair work and toward a more dependable slop oil system. Becht continues to support design refinements and operating guidance — and with a clearer understanding of system hydraulics plus a refined view of how the vessel and pump should operate together, the facility is now positioned for more stable performance in challenging plastics pyrolysis service.