FCCU Reliability Challenges Now and in the Future

Article appears in the March/April 2023 issue of Inspectioneering Journal

Introduction

Fluid catalytic cracking units (FCCUs) have been fundamental to refinery operations and economics for many decades, with the very oldest operating units achieving 70 years of service. With no new refineries on the horizon for the United States and operating demands changing, maintaining these complex aging assets is a consistent and evolving challenge. This article looks at reliability issues common across many licensors, designs, and vintages to help give perspective on where issues may be waiting and how to handle them when they arise.

Proactive Solutions

One way to look at reliability is by breaking it into two main categories: proactive and reactive solutions. An example to draw from for a proactive solution is to look at the package delivery industry and the maintenance practices of their delivery trucks. It is not that often that you see a broken-down truck of a publicly owned package delivery company. The reason for this is the proactive approach these companies take in maintaining their trucks. If the trucks are not on the road delivering packages, they are losing revenue. Through data collection and reliable life prediction methods, these companies are replacing components on their trucks prior to failure. This similar proactive approach can be taken with fluid catalytic cracking (FCC) reliability to improve successful operations between scheduled outages.

Evaluation of Aging Equipment

This proactive approach in evaluating aging equipment starts with having a good documentation process that captures the original design information, inspection, operational, and repair history. Without this information, it is very difficult to do a thorough analysis of repair versus replacement on aging equipment.

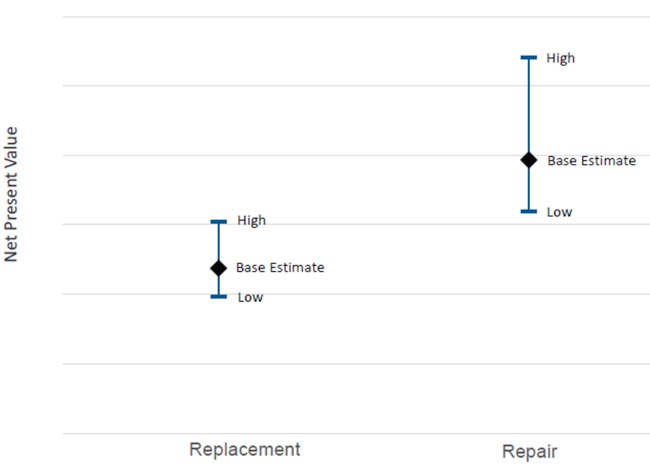

One of the best ways to make an informed decision on aging equipment is to conduct a net present value (NPV) evaluation comparing the cost of repair versus replacement. In this example of a NPV analysis, an approximately 25-year-old FCC regenerator cyclone is analyzed. At 25 years, the regenerator cyclone is at the higher end of industry experience for the life of a cyclone. A multidisciplinary team of process, material, and mechanical subject matter experts (SMEs) reviewed historical information on the cyclones and conducted interviews with key staff members in the daily operations of the FCC unit. A detailed yearly cost analysis was performed, and the NPV is summarized in Figure 1.

The black diamond in Figure 1 represents the base case for the costs associated with replacing the cyclones and repairing the cyclones. The high and low values represent a sensitivity analysis on the base case where contingency was added for the replacement cost, and for the repair case, the cost was added for the difference between a replacement and repair turnaround duration, providing an overall potential cost range.

One of the key technical discoveries from the work was the prior cracking and repair of the primary cyclone hanger-to-cyclone welds. This cracking was attributed to sigma phase embrittlement in the 304H support material. The crack transferred the load to other components, which caused subsequent overload and cracking in other support areas. The shift in load and subsequent cracked support components caused an out-of-plumbness of the cyclone barrels and diplegs. Over time the out-of-plumbness will exaggerate erosion in the primary cyclone barrels, cones, and the dustpots resulting in a reduction of primary cyclone efficiency, higher erosion rates in the secondary cyclone, and higher catalyst carryover. The overall age of the cyclones and the cascading effect of issues was the main driver of the repair net present value being much higher than the cost of replacing the cyclones.

Figure 1. Net Present Value Cyclone Replacement Versus Repair

To view the whole article, visit Inspectioneering

- Full article includes details about:

- Good Design

- Hot Spot Mitigation

- Engineering Assessment

- The Last Tool in the Toolbox

- Reliability Beyond the Equipment Proper

Conclusion

Identifying and being prepared for reliability issues as they come up is a very challenging task, especially with aging equipment and the ever-evolving process conditions. Increasing FCC reliability involves design, inspection, maintenance, and the coordination of repair activities across many stakeholders in the FCCU. To do this successfully and repeatedly takes a multidisciplinary approach of experienced SMEs, experience-based economic evaluations, and practical and reliable solutions complemented with advanced analysis when needed.

Have a question regarding your FCCU Reliability? Contact Becht for assistance: