Energy Savings Hidden in Plain Sight

Pinch analysis is a great tool for identifying heat integration improvements that would otherwise be hard to find. However, many energy-saving opportunities are hiding in plain sight. In this blog, I’d like to share a couple of these simple but valuable opportunities.

The Contrary Feed Cooler

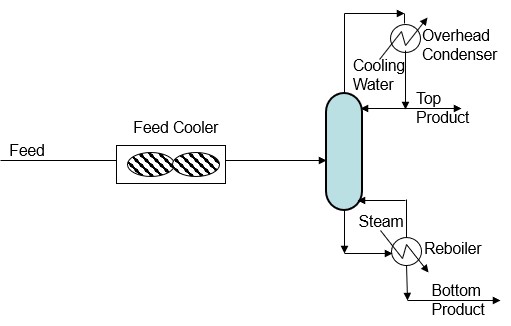

Reviewing process flow diagrams (PFDs) isn’t usually an exciting exercise, but this was an exception. The drawing I was looking at showed a distillation column — one of the largest in a very big chemical complex — with a steam reboiler. It was impressive, but not particularly unusual. What astonished me was the air cooler on the feed stream (see Figure 1). Why on earth…

Figure 1: Distillation Column with Feed Cooler

Distillation is a separation process that uses heat to drive successive stages of vaporization, mixing, and condensation. The heat for this specific distillation column comes from steam that is supplied to the reboiler. If you remove heat from the feed stream, which is what the feed cooler does, the feed temperature goes down and the steam requirement in the reboiler must increase to offset this. In other words, the feed cooler increases the energy use in the column, with no obvious benefit. So why is it there?

I talked with several managers and technical specialists on the site, trying to figure out if there was a legitimate purpose for this cooler. After much debate, we concluded that the designers had anticipated occasional upset conditions that would require removing heat from feed, and the feed cooler was intended only for these situations. However, after the plant was commissioned, it became standard practice to run the fans continuously. After all, the equipment was there; why not run it? So, it ran, wasting energy for more than a decade, until we happened upon it in a PFD review.

A young process engineer ran multiple simulations of the column, and her work confirmed that the air cooler on the feed stream was indeed causing an increase in the reboiler duty. After several weeks, we were able to persuade the plant manager to turn off the air cooler fan. Steam demand for the reboiler immediately dropped by more than 30% without violating product specifications, resulting in a steam saving worth $1,000,000/year, without any investment. That was many years ago. Allowing for inflation, the savings would now be worth about $3,000,000/year. (There was also an electric saving due to turning off the motor on the fan, but the monetary value of this was relatively small.)

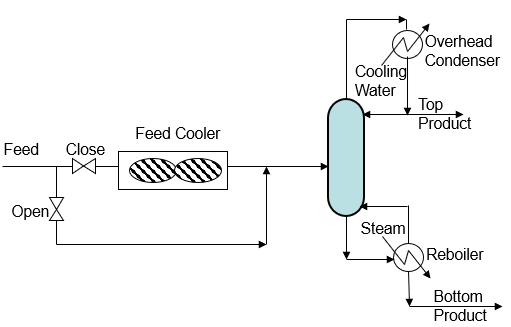

Even with the fan off, natural convection of the air in the cooler still caused significant heat loss from the feed stream. We proposed a small project to eliminate that loss by installing a bypass around the cooler (Figure 2). This would save an additional $200,000/year with a very good payback. However, due to other priorities, the project was not implemented.

Figure 2: Distillation Column with Feed Cooler Bypass

A few years later, I encountered a very similar issue in a distillation column at a petrochemical facility in another country. In this case, they were debottlenecking the plant and had to increase the throughput of the column. They planned to install a larger reboiler, but due to space constraints they could not increase the size of the overhead condenser to balance the heat duties. Their solution was to add a cooler on the feed stream. I wasn’t convinced by their logic, and I pointed out to them that their design would have a significant adverse effect on energy efficiency. While they acknowledged that there would be an energy debit, they could not find any other way to manage the overhead condenser duty, and my concerns were overruled.

Another couple of years went by and I visited that site again. They had implemented their debottleneck project as planned, and I asked how it was working. “It works fine,” my informant told me. He then added, “But we bypass the feed stream cooler all the time. We don’t need it to achieve the required capacity, and it just wastes energy.” I didn’t say, “I told you so,” but the temptation was almost overwhelming.

Fix It and Forget It

Another common cause of inefficiency is unnecessary bypassing of equipment that is designed to improve energy efficiency. This is essentially the opposite of the feed cooler scenarios that were discussed above, where energy efficiency improved when equipment was bypassed or taken out of service.

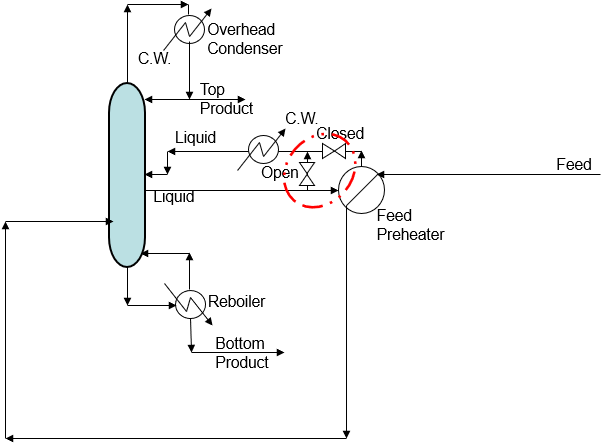

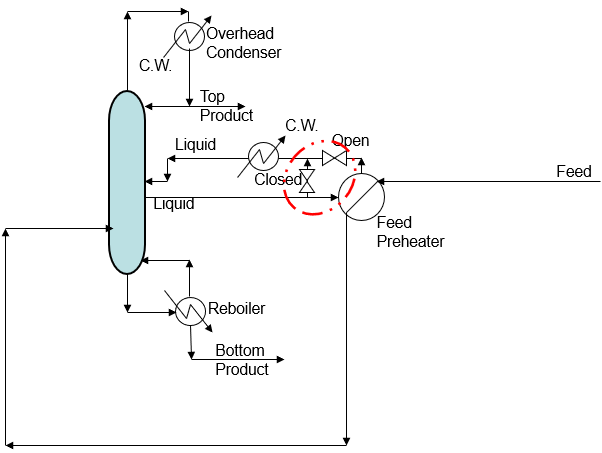

Figure 3 shows an example from an oil refinery. A pumparound on one of the distillation columns has two heat exchangers. The first heat exchanger is a feed preheater – i.e., it recovers heat from the pumparound, and uses it to heat the incoming feed stream. As in the earlier examples, increasing the temperature of the feed stream reduces the heat load of the reboiler, which saves utility heat. The second heat exchanger lowers the pumparound return temperature to control a product specification, and it rejects excess heat to cooling water.

During a cold snap in the winter, the operators opened a bypass around the feed preheater because the combined pumparound cooling duty became too large, and the pumparound return temperature was too low. However, when the ambient temperature rose again, they failed to close the bypass. As a result, the benefits of feed preheating were unnecessarily lost for an extended period of time: the reboiler heat load increased, while excess heat from the pumparound was needlessly rejected to cooling water. This situation could have continued indefinitely, but we saw the valves and questioned the operating staff about valve positions during a site review.

Figure 3: Unnecessary Bypassing of Feed Preheater

Once this inefficiency was recognized, it was readily corrected by closing the bypass and restoring normal operation, saving $600,000/year (Figure 4). In addition, a change was made to the operating procedures to ensure that the bypass valve position is routinely monitored using the refinery’s data historian system. Additional recommendations were made to automate the control system and optimize feed preheating throughout the year.

Figure 4: Closing the Bypass Returns the Feed Preheater to Service

Summing It Up

The contrary feed cooler taught me some important lessons. Operating practices tend to become entrenched over time. Plant operators may dutifully follow procedures that were developed when their plant was commissioned, even when the assumptions behind those procedures are flawed. Added to that, throughput, feedstocks, product slates, and a host of other factors can also change, rendering the original assumptions obsolete. For these reasons it is important to reassess operating procedures regularly. We should also be willing to integrate operating experience into new designs.

The “fix it and forget it” experience provided a slightly different twist. Plant operators sometimes make changes as a result of short-term issues – and then forget to revert when the issue has been resolved. This is a very human thing to do. As a result, many valves are left closed when they should be open, or open when they should be closed; many pieces of equipment are in use when they should be off or vice versa; and many process set points are chosen without proper consideration of their impact on energy utilization. The basic problem is a lack of communication – or perhaps a lack of proper documentation. Maintenance tracking systems have improved over the years, and this particular incident occurred when electronic reminder systems were still in their infancy. (Yes, I am a dinosaur.) However, even the best electronic systems – including AI – still require a human interface, and if we don’t pass information along to the right people at the right time, important things get missed.

These examples show how easy it is for inefficiencies to go unnoticed or persist due to outdated assumptions and overlooked details. Identifying and correcting them can uncover substantial savings opportunities with little to no capital investment. Contact us today to learn how Becht can help.

Like what you just read? Join our email list for more expert insights and industry updates.

More Information

Rossiter, A. P., “Back to the Basics,” Hydrocarbon Engineering, Vol. 12, No. 9, pp. 69–73 (September 2007).