Contracting for Plant Outages

~ A Comprehensive Contracting Plan is an Important Building Block to a Successful Plant Outage ~

During planned maintenance outages, many facilities must contract out a significant portion of their work. Contractor selection is an important step that involves securing the qualified contractor personnel, given the critical role they play in successful outages. Furthermore, a comprehensive contracting plan will ensure that all key stakeholders agree with recommendations on the scope of contracting, contract development and compensation strategies, contracting opportunities and constraints, and contract work assignments. Finally, the plan should detail responsibilities for all contract deliverables as well as required timelines.

Importance of Contracting for Plant Outages

Plant outages, whether planned or not, are always an expensive proposition for those of us in the continuous manufacturing industries. Because labor is typically the highest cost component in these, labor efficiency will most likely determine the final cost and duration of the outage.

In many cases, the facility will not have enough labor on hand to complete the work during the outage, necessitating the outsourcing of all or part of the scope to third parties.

A comprehensive contracting plan becomes a key step to success when this is required, as it is with all good practices in preparing for the outage.

Contractor Selection

There is an overwhelming amount of literature that covers the different methods or approaches to contractor selection. We will not attempt to review these here as they can be largely influenced by both internal or external requirements and constraints within the organization. This author will simply share what he believes are the most important factors in selecting contractors to best ensure meeting the outage’s objectives.

The best predictor of success is demonstrated recent past performance in similar work, whether at the facility in question or at comparable ones. Of course, this applies to all dimensions of performance, such as work safety, meeting target schedules or budgets

The importance of the contractor’s key personnel cannot be overstated. Here again, their recent experience is what counts the most. A good ‘test’ for this is to ask the potential contractor’s leadership team three questions:

- How will you select your key staff to be assigned to your scope of work and why?

- How do you plan to deploy them during the planning phase of the outage and why (if applicable)?

- Finally, same question 2. but in the execution phase of the work

The need for early involvement by the contractor’s key personnel well before the start of the field work is highlighted in question 2. While there is an additional cost to the facility, the benefits of doing so outweigh the additional expense.

Personnel from the contractor’s detailed planning effort can subsequently be assigned to key execution positions, allowing for a smooth transition from planning to field work. In this author’s experience, one successful example is when the contractor’s employee in charge of planning all the piping work during the outage was reassigned as the night shift execution superintendent.

They can provide invaluable input into work execution options such as:

- Adjusting the work scope to minimize field work where possible, including repair vs. replace options

- Due to access or other constraints, optimizing the order in which tasks are completed. This is reflected in the job plans by the relevant predecessor and successor designations.

Making the execution contractors responsible for the majority of the prefabrication or preassembly of the material to be installed during the outage is also related to this approach. This should include the trial assembly of components that will be installed inside production machinery and other equipment.

Finally, making the execution contractors responsible for gathering, labeling, and safely storing all of the materials they are responsible for installing will help minimize lost productivity during the outage.

Contracting Plan

The main goal of a documented contracting plan is to ensure that the site’s leadership team and other stakeholders are on the same page about who, what, and how the outage work will be distributed.

Specifically:

- Confirm that contracting for the work’s execution is optimized and implemented to meet or exceed the outage’s objectives, whether they are related to workplace safety, work quality, duration, or cost

- To ensure that key contracting principles, assumptions, and constraints are agreed to

- Agree on the responsibility split for outage planning and execution between the company and the contractor(s)

General Contracting Overview

The plan should include the most important principles, assumptions, and constraints that will affect how contracting is developed. As previously stated, these are critical in ensuring that the outage’s stakeholders are on board with the proposed strategy.

Execution Approach

This must be determined first and foremost, and will be heavily influenced by the scope of work (size, complexity), the availability of the site’s labor force, the current local or regional contracting environment, and other factors.

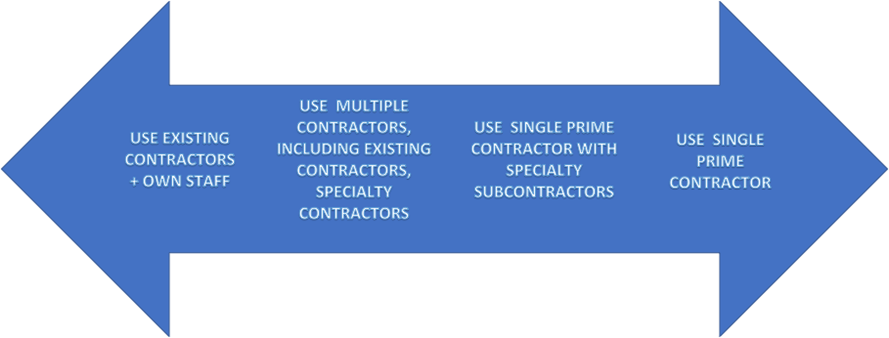

This decision is best viewed on a scale, as shown in Figure 1.

Figure 1 – General options available for outage execution as it relates to contracting

Contract Competitive Tendering or Sole Sourcing

Following the recommended execution approach, the contracting plan should specify which contracts or disciplines (e.g., civil, mechanical, electrical, etc.) will be competitively tendered and which will be sole sourced, with negotiated terms and compensation.

When drafting this proposal, several factors must be considered, including:

- The scope and complexity of the outage

- The current and anticipated competitive environment at the time of the outage

- Contracting policies and procedures within the company

- Contracting performance in the past

General Principles for Contractor Compensation

This is a complicated subject, and many organizations have requirements or, at the very least guidelines, that must be followed.

Different perspectives on how to allocate business risks, incentives or penalties, and industry relationships may all play a role in developing compensation schemes.

Nonetheless, the compensation principles should be recorded, keeping in mind the contracting plan’s main goal (stakeholder alignment). An example is shown in Figure 2.

| Work Scope Definition | Examples | Compensation Options |

| Work scope well defined & documented; little or no possibility of discovery work; limited interface with other work; mostly straightforward access to work face | Full / complete equipment replacements; new installations | Fixed-price or unit-rate contracts |

| Work scope defined & documented; moderate possibility of discovery work; limited interface with other work | Major equipment repairs or modifications | Reimbursable cost with fixed or variable fee contracts |

| Work scope outlined but high likelihood of discovery work, or definition is condition-based after start of outage; significant interface with other work or trades; difficult access to work face; significant work interruptions expected | Equipment repairs; equipment cleaning; general outage support | All-inclusive rates; time-and-material contracts |

Figure 2 – Example of contractor compensation schemes.

This table proposes different compensation methods depending on either

(1) scope definition, including possible discovery work, (2) interface with other work and

(3) ease of work access.

In relation to compensation, the plan should state what contract incentives or penalties, if any, will be applied to the various third-party agreements. The plan will need to reflect the organization’s most recent guidance or local / regional industry practices on this topic once again.

Finally, some incentives or allowances may be required in order to secure the necessary labor pool to complete the outage. This should be part of the contracting plan.

New to Site Contractors

New to site contractors may pose a unique risk to the location in many aspects of their performance due to their inherent unfamiliarity with the work site (workplace safety, productivity, and so on).

- A prequalification review with minimum acceptance thresholds is used by many locations. This examination usually focuses on workplace safety programs and performance, technical qualifications, and key personnel’s experience with similar outage work

- Developing and implementing an onboarding or assimilation plan for all new site contractors is a good practice. One element could be to embed some of their key personnel within the site’s organization well before the outage begins, allowing them to become more familiar with the owner’s staff, programs, facilities, and infrastructure, among other things

Site’s Outage Execution Capability

Another consideration in the contracting strategy is the site’s contracting ‘capacity’. First and foremost, when known, this includes individual contractors’ demonstrated outage execution capability. This will have a significant impact on how much work (in terms of size and complexity) can be distributed among the various third-party vendors.

Second, logistical constraints, such as plot space for temporary buildings, may limit the number of contracting companies that can be hired. Furthermore, organizational constraints, such as the site’s own resources available to properly administer all contracts, may come into play.

These and other relevant actors must be included in the contracting plan because they will influence how many contractors are assigned to the various parts of the scope of work.

Other Considerations

Before concluding with the roles, responsibilities, and work scope allocation, the plan should consider any other relevant considerations.

Current Competitive Environment – Recent mergers may have reduced the number of qualified contractors available. Others may have simply stopped doing business. On the other hand, new entrants into the market are possible.

Local or Regional Activities – The number of qualified contractors available – and, more importantly, the availability of their key personnel – may be influenced by the number of local or regional outages or similar work.

Labor Availability – This could become a constraint, so the contracting plan should address how it can be mitigated. Particularly for specialty trades, the plan should consider the expected availability of local or regional labor. Only a few global suppliers may be able to provide some very unique services. These will almost certainly necessitate lengthy lead times to secure and mobilize.

Contracting Plan Implementation Responsibilities

Individual positions responsible for implementing the plan elements are outlined in a separate section of this document:

- Contractual documents and job specifications

- Contract creation, including market research

- Tendering, assessment, and awarding

- Administration of contracts

- Contract closure and evaluation

Contract Work Assignments

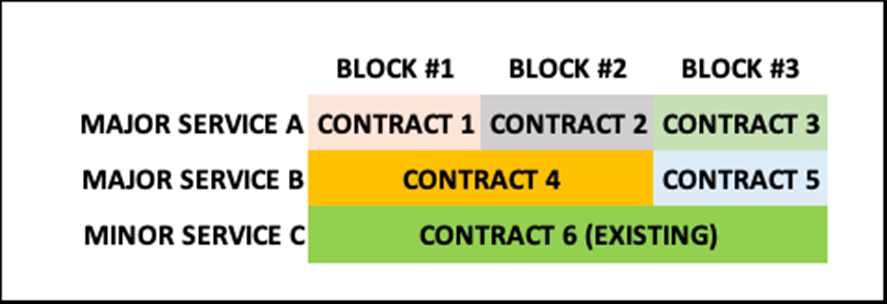

Finally, the recommended contract assignments are presented, taking into account all of the above. This is usually determined based on the plot plan of the facility, the scope of work, and site infrastructure considerations. Figure 3 shows an example of how this can be presented effectively.

Figure 3 – Example of contract assignment. The blocks denote the various geographic areas of the site where outage work will be carried out. Significant portions of the scope of work, usually for a single or related trade, are represented by the major services. The critical path duration of the outage and the majority of the work-hours are usually found in the major services. Minor services are needed for support and related tasks.

In this case, major services were allocated based on the contracting plan’s opportunities and constraints. A standing site contractor will provide the minor service throughout the facility.

Timing and Deadlines

The contracting plan’s final section details the required timelines for all aspects of the outage’s contracting. This should be in line with the strategic and detailed planning schedule for the outage.

Due to the potential complexities of dealing with immigration and permit requirements, international or other vendors that require a long-lead time to secure must be clearly identified with sufficient schedule allowance.

Better outage execution practices necessitate the early involvement of key contractors (this will be the subject of a future paper). This must be factored into the contracting strategy.

Conclusions

We understand the value of contracting in the success of maintenance outages. There is no one-size-fits-all answer for the scope and depth of contracting that will produce the desired results – it all depends!

- The user’s experience on the site

- In light of the current economic and business climate

- To some extent, depending on the scope and severity of the outage

These factors, among others, will influence how much or how little third-party contracting is done. As listed in this article, there are numerous factors to consider, each of which must be weighed against the others.

Understanding the current circumstances and constraints at the site and documenting them in a comprehensive contracting plan is critical. Its primary goal is to ensure alignment with the outage’s stakeholders, as well as to establish clear responsibilities and implementation timelines. Check out Becht’s service line HERE.