Fired Heater Services 2021 Highlights

2021 was an interesting year for Becht Fired Heater Services. Below are a few of our more interesting projects or findings.

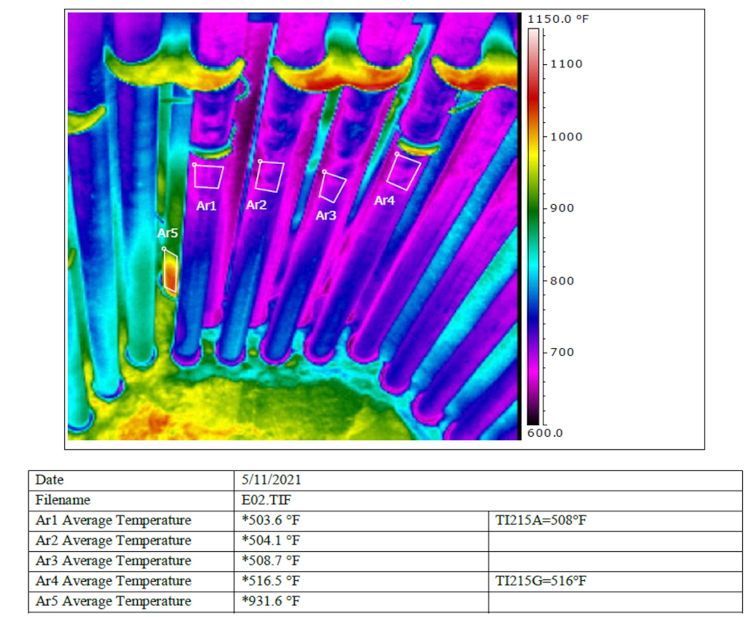

- Shock tube coking discovery – Very localized coking in the shock tube section of a small crude heater. These coked locations, one shown below on Ar5, were running substantially hotter even than the lower radiant tubes. This was also a carbon steel tube application where damage will typically occur quickly once tube mid wall temperatures start to exceed 950 F. Thankfully a routine IR scan identified the hot spot and provided time for the site to get ready for an unplanned mechanical decoke. While a decoke may not be great out of the blue, it is still better than a tube failure and the resulting damage!

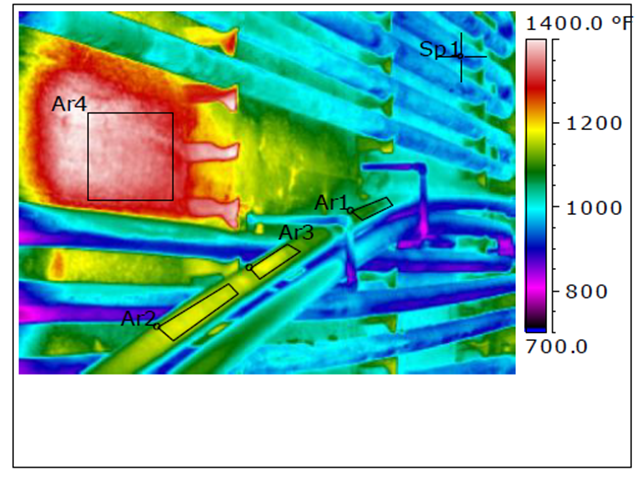

2. Operating hooked tubes to a safe limit – Through an operating upset a cabin style crude heater suffered a jump and partial fall of two mid elevation pass tubes. The tubes were successfully stabilized, and rigorous stress calculations preformed to confirm maximum operating temperatures. Once the operating window was defined, routine and accurate thermography was critical to safely pushing the unit to a safe limit. So far, these tubes have operated safely just below their temperature limit for 6 months, with 3 months to go before the repair window. The primary focus of keeping the tubes safe and reliable has been achieved, and along the way refinery rate was directly improved by knowing if there was room to run the heater harder. The routine monitoring also flagged burner issues and justified more routine cleaning before there were major issues.

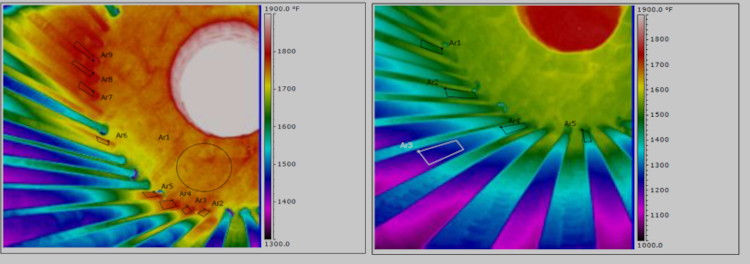

3. Deactivated catalyst catch/monitoring – Steam methane reformers (aka SMRs) are always an exciting fired equipment application because the tubes are packed with catalyst. When this catalyst deactivates or is damaged tubes can operate at very high temperatures very quickly. Threading the needle on tube temperature when this happens with expert thermography can add months of safe operation and buy time to prepare for an outage. The images below show a recent SMR monitoring project before and after the catalyst change out (same firebox, much better looking tubes with the new catalyst on the right). Thermography helped catch the issue, monitor it over 5 months, and ultimately drive when the right time to shut down and fix the problem.

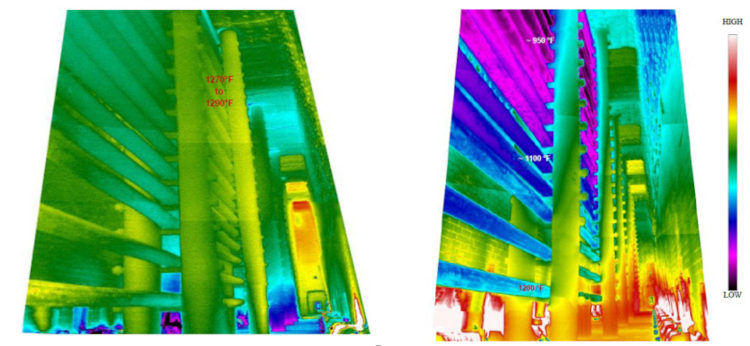

4. Accidental heat soak – Delayed coker units with mule ear configurations tend to have leaks which are sometimes hard to address. In this instance 1 cell of a 4 cell Foster Wheeler configuration was going to be kept in a “hot condensate” mode at min fire for a few weeks to bridge to a planned repair window to allow repair access. Unfortunately, the condensate flow through the tube was inadequate to prevent the tubes from reaching firebox temperature, which even at minimum firing was over 1250 F, the typical limit for chrome tube applications. The tube thermocouples missed the high temperature operations due to placement towards the bottom of the coil, which is typically the hottest area, but was not in this operating mode. Thermography caught the pass was essentially “heat soaked” and operating above its temperature limit. This allowed the operations team to act, and thankfully get the tubes back under the limit to prevent damage while the system waited for the outage window.

Pass 4 high temperature operation condensate “park mode” (Left), Normal online pass (Right)

Becht brings a full suite of expertise to improve fired heater operations through field-based assessments and remote analysis. Do you have a good handle on all your heater limitations and constraints? Are you truly optimizing your run cycles to a safe and optimized limit? Contact Becht for more information on Becht Fired Heater Services.