Introduction to Refractory

Welcome to the first of a five-part blog series on refractory for petrochemical applications.

This first blog is an introduction to refractory that covers the common refractory-lined equipment, future blogs will discuss materials and designs and quality, inspection, and work scope planning.

Refractory is a ceramic material that maintains its strength while resisting damage by heat, pressure, and chemical attack. In the refinery, refractory can come as refractory ceramic fiber (RCF), as a castable or gunned material to be mixed with water, or in brick form. Each of these can be combined to provide equipment with the necessary thermal, erosion and corrosion protection. Each of these is applied in the following key refining applications.

Fluid Catalytic Cracking Units

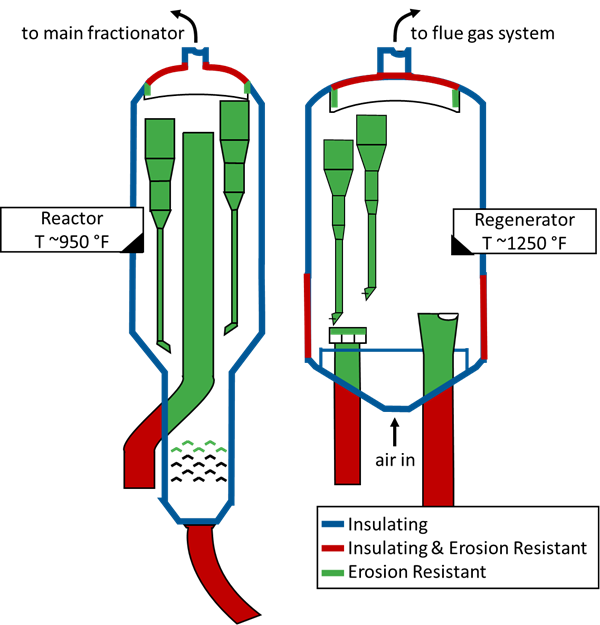

One of the most complex refractory consumers is the Fluid Catalytic Cracking Unit (FCCU), requiring multiple combinations of different refractories. These units require circulating catalyst and high temperatures to make their products, both of which would be a challenge for bare steel vessels. In the FCCU, refractory materials generally fall into three categories: insulating, erosion resistant, and partially insulating, partially erosion resistant. See Figure 1 below for additional details.

Figure 1. A schematic showing how insulating, insulating and erosion resistant, and erosion resistant refractory are used throughout the reactor and regenerator vessels of a typical FCCU.

Fired Heaters

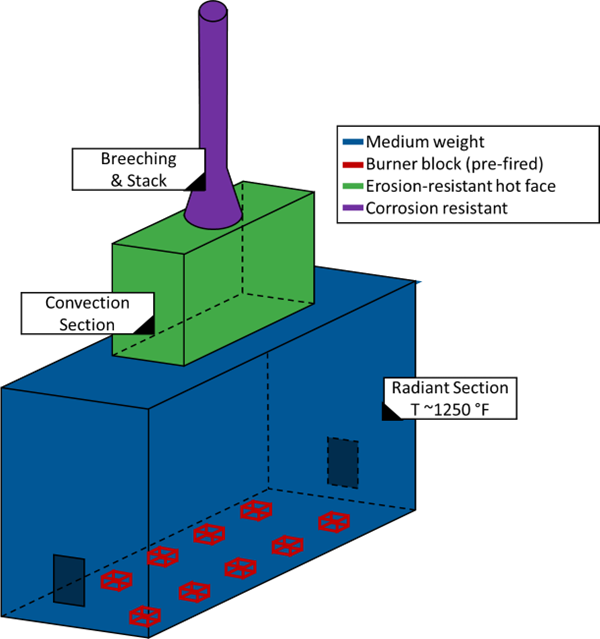

Fired equipment may employ fiber, castables (monolithics), or brick refractory as well as any combination of the three depending on specifics such as vintage, fuel, or severity of service. Higher temperature furnaces tend to maximize use of refractory ceramic fiber, often in edge-grain or folded modules. On the other hand, firing on heavier fuels employ superduty firebrick to resist the effects of ash and flue gas corrosion. Brick can be employed in a dual-layer lining to protect the backup/insulating layer of castable refractory that is providing the thermal protection to the steel. Refractory in heaters and boilers needs to be especially durable as major repairs require removal of the tubes. For a generic refinery service furnace, an example refractory lining is below (Figure 2).

Figure 2. A schematic showing how medium weight, lightweight, burner block, and corrosion resistant refractory are used throughout a typical refinery service heater.

Claus Thermal Reactor

Sulphur recovery units have the most interesting refractory in the Claus Thermal Reactor containing the main burner. Operating in excess of 2000 °F, brick refractory is the best product for the hot face. Brick continues to outperform other refractory types with the increasing use of oxygen enrichment for additional throughput (and associated increase of operating temperature). When manufactured, bricks are high-fired to beyond the process temperature so that high strength bonds can develop in the material. Compared to a castable, which develops its strength during dry out or process start up, bricks are much better in creep resistance. The SRU Thermal reactor refractory lining is critical to reliable process. However, these bricks are poor in insulation, so a backup layer of insulating castable is required to protect the shell.

Metallic Anchors

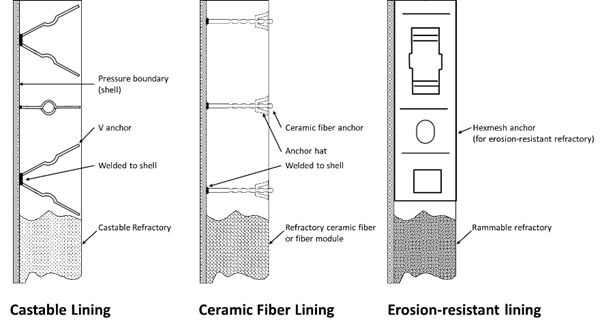

For many refractory lining applications, reliable performance also depends on metal anchoring. Anchors come in a wide variety of shapes, but in general, secure the refractory lining to a steel component that provides structural support for the lining. Refractory ceramic fiber linings are typically installed onto studs and secured with a mechanically locking cap. Ceramic fiber cut or folded into modules rely on integral anchors that are installed by stud welding. Castable linings are anchored by wire anchors in a V or Y shape. Bricks are often self-supporting in gravity walls or arches but can also be supported with metal anchors. When combined with bricks, metal anchors usually take the form of tiebacks, which hold the bricks in relative position while allowing for thermal expansion. Erosion-resistant linings, when used to protect steel internals from wear in linings, can be installed as thin as ¾” into hexmesh anchoring. The design of the hexmesh accommodates for the differential thermal expansion between the refractory and the underlying steel. Several examples of linings with anchors are shown below (Figure 3).

Figure 3. A schematic showing generic refractory lining details for a castable, and ceramic fiber, and a thin-layer rammable lining with anchors.

Refractory-lined equipment are essential to every refinery. It is the critical detail that enables construction of boilers, furnaces, and large vessels to be fabricated from carbon steel instead of expensive and demanding heat-resistant alloys. Quality lining design requires a combination of lining types and materials installed into a different anchor depending on the exact combination. The next post will discuss the properties that ensure the right refractory for the job as well as more detail about lining designs and combinations.

For questions, comments, and discussion of edge cases, eventualities, or exceptions contact one of Becht’s mechanical experts.