CorrExpert®-Crude: Corrosion Prediction and Material Selection for Refinery Crude Corrosivity Applications

State-of-the-art Cloud-based Decision Support Model drives enhanced crude processing flexibility and unit mechanical integrity through accurate, simultaneous quantification of naphthenic acid and sulfidic corrosion

Refinery Crude Unit operations, characterized by significant process complexities and crude blend / fraction assay properties, have traditionally remained an area where accurate asset integrity and life prediction have been difficult to achieve. Such difficulty stems from the need to characterize and correlate corrosion across widely varying unit operating scenarios and process conditions; quantifying corrosion has thus become a key factor in ensuring asset integrity, and absence of appropriate corrosion management strategies has often been the cause of some of the most destructive and expensive corrosion failures.

Changing feedstock and process chemistry, coupled with the need to constantly meet demanding production targets, exacerbate the challenges with understanding and managing corrosion, a phenomenon defined at the intersection of process phase behavior and thermodynamics, multiphase fluid dynamics, and metallurgy. One of the primary impediments to overcoming this complexity has been the absence of quantified corrosion data that can be correlated to unit operating / process conditions.

Naphthenic acid and sulfidic corrosion in refinery crude unit operations have often led to conservative decision making in terms of crude selection, crude processing, and unit metallurgy specifications. Additionally, the refining industry has constantly sought, for reasons of improved economics and ROI, to move in the direction of processing heavier, high sulfur, high acid opportunity crudes. Such a directional shift has been a consequence of depleting reserves and declining sweet crudes. Processing of low-cost opportunity crudes available in the market has become imperative to improving refining margin.

Based on decades of fundamental crude parametric analyses and corrosion research as well as extensive experimental simulation and data, Becht has developed the industry’s first ever simultaneous naphthenic acid and sulfidic corrosion prediction and analysis framework, CorrExpert®-Crude, which is foundational to quantifying naphthenic acid and sulfidic corrosion correlated with unit process data and operating data. The model seamlessly correlates unit process/operating data with unit metallurgy as a means to predict metal loss rates and remaining life for CDU/VDU piping exposed to hot oil conditions.

This cloud-based application enables realization of the business need to work with opportunity crudes without risking corrosion damage to CDU/VDU equipment. Leveraging crude assay data and information available through process historian, the framework can also facilitate enforcement of appropriate dynamic (not fixed) Integrity Operating Windows (IOWs) through utilization of corrosion rate as an IOW parameter alongside other key operating variables, such as TAN, sulfur, and temperature. The system’s ability to seamlessly collaborate with other cloud-based process and refinery applications has important implications for the creation of a true digital twin, integrating real-time operating data and automated predictive analytics as a means to achieve crude processing flexibility, improved reliability and enhanced profitability.

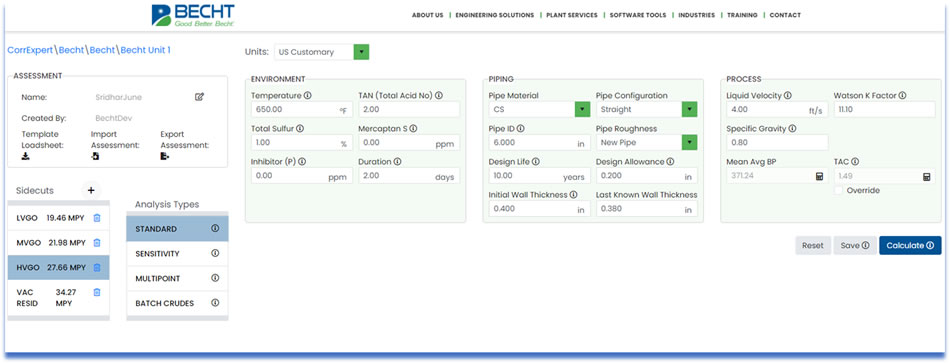

CorrExpert-Crude provides an intuitive, browser-based user interface (Figure 1) designed to quickly capture relevant user inputs to predict/quantify corrosion rates for various metallurgies typically utilized in CDU/VDU unit operations.

Have a question regarding CorrExpert®-Crude? Reach out to a Becht expert regarding your future plans by clicking below.

Figure 1: CorrExpert-Crude User Interface

Based on the user data for the process environment and piping systems, CorrExpert-Crude will predict corrosion rates and offer a number of corrosivity-related insights, including:

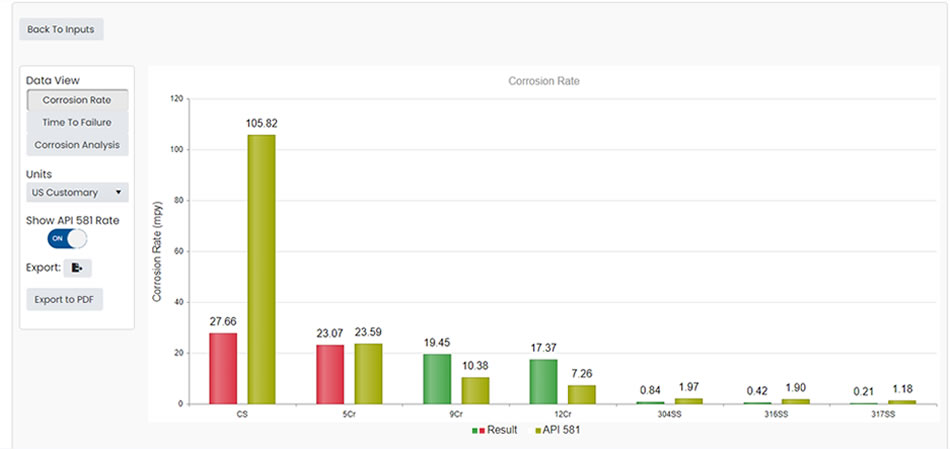

- Comparison of corrosion rates for commonly used materials of construction and with API 581 (Figure 2)

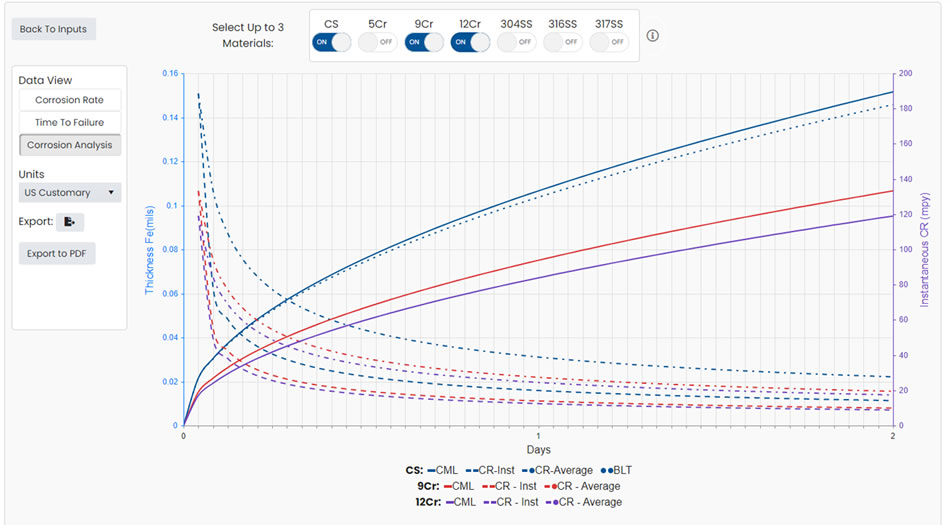

- The ability to track cumulative metal loss, instantaneous corrosion rate on a time scale as well as the average corrosion rate (Figure 3)

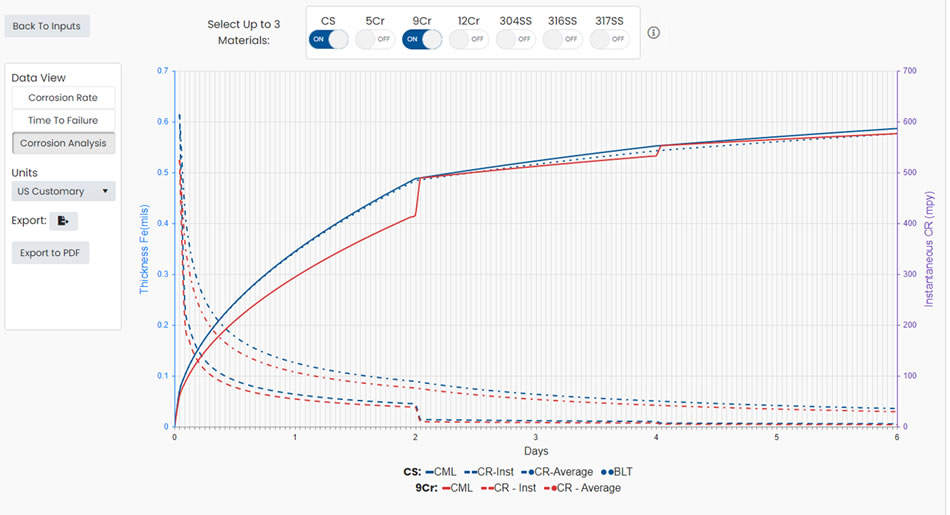

- Quantification of batch crude operations over time to assess optimal sequencing of crude blends and the ability to incorporate the effect of any FeS barrier layer protection on subsequent crudes (Figure 4)

Figure 2: CorrExpert-Crude Corrosion Rate View

Figure 3: CorrExpert-Crude Corrosion Analyses Results

Figure 4: Batch Crude Operations Through Optimized Crude Sequencing