CorrExpert-eCCD

![]()

Why eCCD

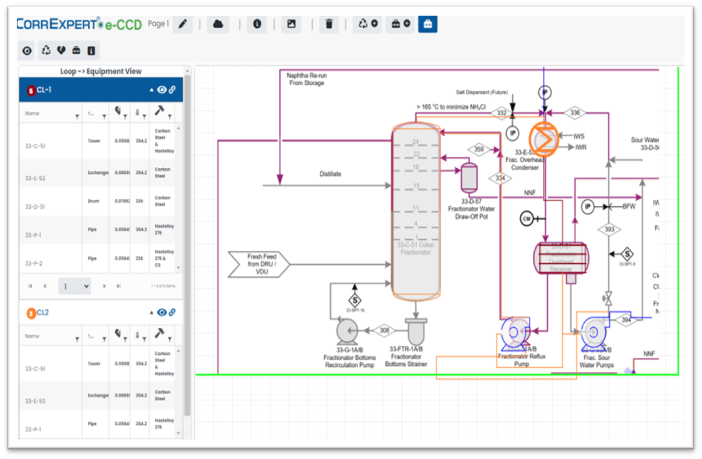

An eCCD is a digital repository of corrosion and reliability information related to a plant unit and/or operating facility

- Process descriptions and primary damage factors

- Mechanical / Metallurgical information about equipment and piping

- Correlations between process parameters and damage mechanisms organized by corrosion loops and circuits

- Piping / equipment wise tracking of critical factors and locations for inspection and monitoring

- A one-stop document for all things corrosion, safety and reliability including risk factors and integrity operating windows (IOW)

DIGITAL KPI DASHBOARD

CorrExpert-eCCD offers seamless access to Key Performance Indicators through real-time integration of data from process historian and IDMS system into the eCCD application:

- Facilitate dynamic evaluation of corrosion precursors and operating limits

- Enable dynamic IOWs through simultaneous tracking of corrosion rates and critical IOW parametric limits

- Ensure focus on hotspots and key CMLs to enable real time reliability management

CLOUD-BASED ACCESS

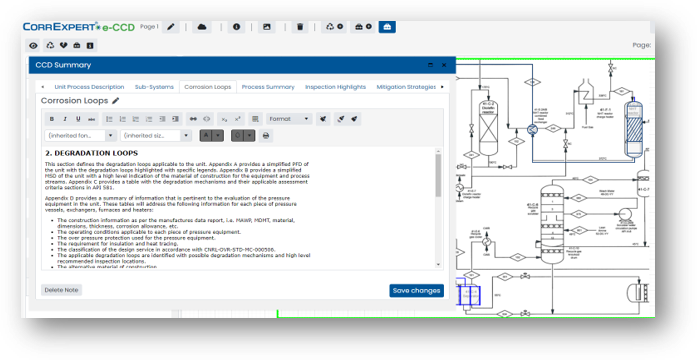

CorrExpert-eCCD offers a visual viewer linking key CCD elements, such as corrosion loops, damage mechanisms, MOC, corrosion rates in a contextual color-coded interface

Designed to provide accurate and continuous technical info, the eCCD facilitates continuous ever-greening of critical CCD elements

Digital Future

CorrExpert-eCCD offers seamless access to Key Performance Indicators through real-time integration of data from process historian and IDMS system into the eCCD application:

- Cloud-native application with the ability to link up to other cloud data sources and analytical / predictive applications

- A one-stop digital framework to integrate guidelines from Reliability, Inspection, Process, Operations, Planning, Procurement and Plant Management

- Can easily be integrated into existing RBI framework to drive intelligent risk analysis and management.