Project Best Practices – Start-up of an Advanced Work Packaging Program, Part 1

“What’s holding you back?”

“How can I improve safety and productivity on my projects?”

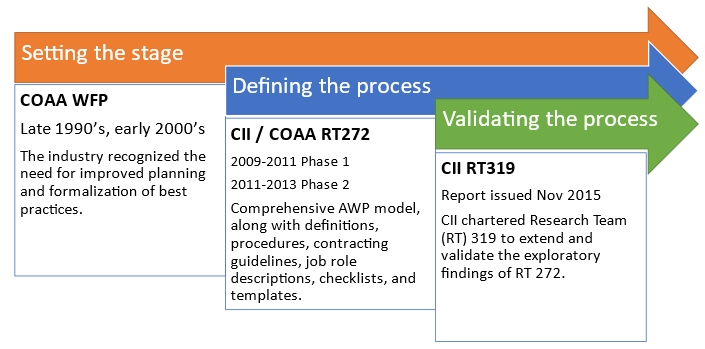

Great questions. Advanced Work Packaging, or AWP, has been identified as a best practice for projects by the Construction Industry Institute (CII) and by the Construction Owners Association of Alberta (COAA). While good project planning has always been an important part of successful projects, formalization of best practices began to take shape in the construction industry in Alberta, Canada in the late 1990’s and early 2000’s. Recognizing the need for standardization and improvements in construction planning, COAA formalized the Workface Planning (WFP) best practices. Simply stated, the end goal of Workface Planning is to provide constraint-free, well planned construction packages to construction field supervision and construction crews so that they have an opportunity to safely build with high levels of productivity. All the engineering, all the materials, all tools, all equipment is available so that the crafts can do what they do best.

The significant contributions of the COAA Workface Planning Committee to document the field of Workface Planning laid the foundation for further research. Complimenting this work, a CII research team was initiated in 2009 to build upon workface planning. CII Research Team (RT) 272, Advanced Work Packaging: Design through Workface Execution established best practices for the entire project lifecycle from front-end loading through detailed engineering and then into construction planning, and ultimately into commissioning and start-up. In addition, the CII team tested the process, and data was collected on project performance. For projects executed with high levels of AWP maturity, impressive results were realized. The results indicate there is opportunity to achieve:

- Up to 25-percent increase in field productivity

- Up to 10-percent decrease in total installed cost (TIC)

- Improved schedule performance, with projects delivered on schedule

- And, most importantly, improved safety performance.

As a follow-up, CII commissioned RT-319 Transforming the Industry: Making the Case for AWP as a Standard (Best) Practice. The research goal was to validate the performance success of the AWP execution model and make the case for AWP becoming a standard (best) practice for the industry. Multiple project case studies were completed along with project surveys and expert interviews.

AWP Fundamentals

For part 1, a good question might be, “How do you answer – what is AWP?”

The answer: It depends on the audience…

For the Project Owner

- AWP is an opportunity, through improved planning, to improve project safety and construction productivity and, thereby, reduce project cost.

- AWP is gaining momentum with industry peers, and it is recognized as an industry best practice.

- So, if not AWP…what else are we implementing to address continual improvement?

For Engineering

- AWP is supporting the engineering team for success through early construction input for improved design.

- The planning steps will occur for every level of project detail. It is most efficient to perform the planning with support from the engineering team…and early.

- The great engineering tools can be used in the field including the great engineering models.

For Construction

- AWP is “Getting Construction involved earlier than before.”

- AWP is “Getting Engineering to design for Construction.”

- AWP is changing the mindset “Construction is the customer of the engineering.”

More to follow in part 2 including

“What if I am just starting to spell AWP? What do I need to do?”