BRAVO – Maintenance Improvement Program Observations on Inventory Management

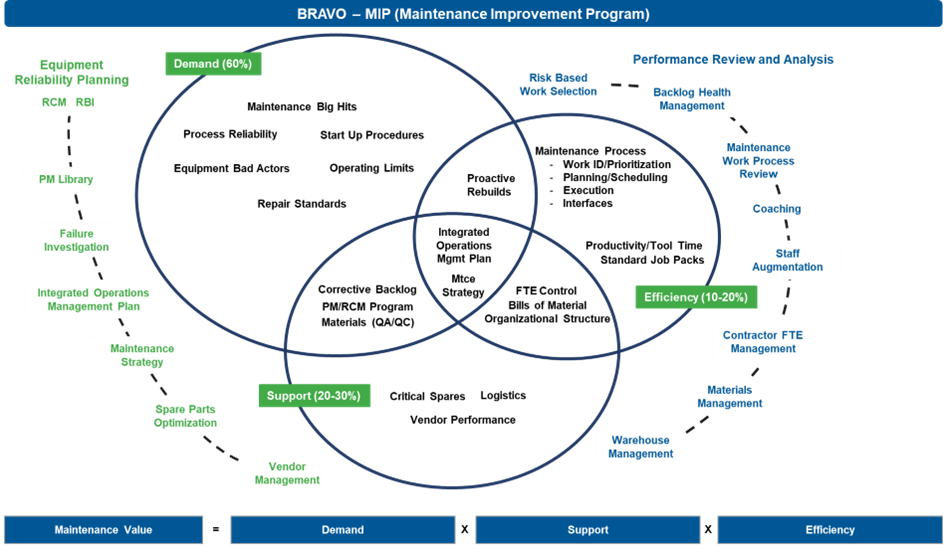

Becht’s Maintenance Improvement Program (MIP) looks at all aspects of maintenance value including the support driver. The support driver consists of those elements which support the delivery of maintenance:

Studies in the construction industry indicate that 1% improvement in material management improved productivity by as much as 43%. While that number can’t be taken to petrochemical sites, we can say that improving material management will result in improved productivity. A petrochemical industry thumb-rule states that a 10% improvement in productivity will result in 1% maintenance cost reduction. Therefore, the case for improving material management is clear.

Common issues with material management that Becht has seen at sites include:

- Excessive stockouts

- Low inventory turnover

- Inadequate off-shelf coverage/security

- Excessive late deliveries

- Lead times not up to date

- Absence of effective material standards

This blog will deal with the first 3 issues. The remaining issues will be the subject of a future blog.

Inventory Optimization

Inventory optimization helps with excessive stockouts and low inventory turnover. There are 3 tools that should be used to optimize inventory beyond historical min/max levels.

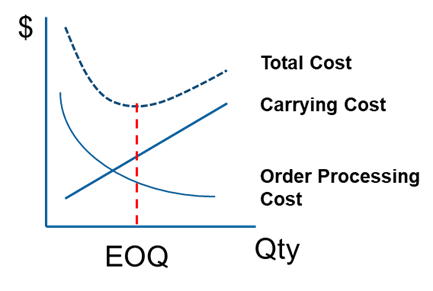

The first tool for optimizing inventory Economic Order Quantity (EOQ). The annual carrying cost of stock is typically 25-35% of the cost of the stock. In EOQ, the carrying cost is balanced against the processing cost and the quantity of stock is based on the total cost as shown in the figure to the right.

The first tool for optimizing inventory Economic Order Quantity (EOQ). The annual carrying cost of stock is typically 25-35% of the cost of the stock. In EOQ, the carrying cost is balanced against the processing cost and the quantity of stock is based on the total cost as shown in the figure to the right.

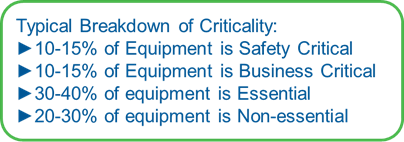

The second tool is the concept of safety stock. Safety stock is additional stock to prevent an out-of-stock situation. Additional stock costs us in both the cost of the stock and the carrying cost of the stock. Equipment criticality should be used as a basis for the determination if safety stock is needed. Some sites do not correctly identify critical equipment. If the equipment criticality at the site does not fall within the benchmarking ranges shown in the figure to the left, then the equipment criticality should be revisited.

The second tool is the concept of safety stock. Safety stock is additional stock to prevent an out-of-stock situation. Additional stock costs us in both the cost of the stock and the carrying cost of the stock. Equipment criticality should be used as a basis for the determination if safety stock is needed. Some sites do not correctly identify critical equipment. If the equipment criticality at the site does not fall within the benchmarking ranges shown in the figure to the left, then the equipment criticality should be revisited.

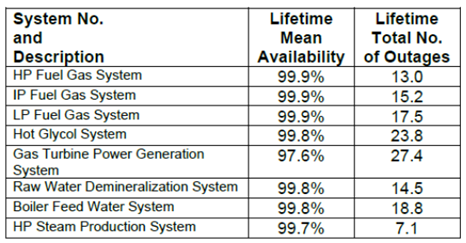

Reliability Asset Modeling (RAM) uses reliability block diagram methodology. This methodology predicts the availability of equipment and systems. Modelling different “what if’s” allows the simulation of the effect of warehouse spares which enables the determination of the stocking strategy.

Reliability Asset Modeling (RAM) uses reliability block diagram methodology. This methodology predicts the availability of equipment and systems. Modelling different “what if’s” allows the simulation of the effect of warehouse spares which enables the determination of the stocking strategy.

Warehouse Service and Access Levels

The issue of inadequate off-shelf coverage/security is addressed by implementing and enforcing warehouse access levels. Warehouse service levels ensure that there is a consistent expectation of when parts will be available for planned work. Warehouse access levels is a part of ensuring inventory accuracy.

Typical service levels are: Typical access levels are:

Shipping: 24 hours Level 1 – High level of access e.g. zone stores

Receiving: 48 hours Level 2 – Secondary access e.g. kitting areas

Deliveries: 24 hours Level 3 – Low level of access e.g. instrument areas

Hot Shots: Processed Immediately

Restricting access to kitting areas also supports inventory accuracy removing the ability to use a kitted part for another job without approval.

Conclusion

When facing supply chain and warehousing issues, the best way to get started is to compare industry benchmarks to your current performance. Looking at the gaps helps identify the areas that need to be improved. There are industry practices and tools available for each improvement area. If you have trouble envisioning how to get started, Becht can help with assessing your situation and helping you implement the path forward. Drop us a note.