Comparison Of Heat Exchanger Cleaning Methods

When a heat exchanger is cleaned the expectation should be that it will now deliver the maximum possible heat duty. But an evaluation of most post-clean operation will show that the cleaned heat exchanger is delivering only about 85% of what should be the clean heat duty.

For critical heat exchangers which impact process performance or energy consumption, that remaining 15% could translate to large losses. To get to clean performance the foremost thing to consider is the cleaning method – is it the best, optimum, most cost-effective for a given heat exchanger? Heat exchanger specialists at Becht can help you identify the most effective cleaning method for a specific service and quantify the associated benefits.

Hydroblasting – The use of high-pressure water jets to force fouling off both the inside and outside surfaces of tubes – has been used as the default method for many decades. This process is labor intensive and an HSE risk unless robotic cleaning is used. Because it depends on labor, it can be low cost in some parts of the world but very high in others. The effectiveness of this method is around 85%. The low effectiveness is mostly a result of the pressure of the water jets not being able to reach deep into the shellside, all around the tubes, and around U-bends on the inside of the tubes.

Chemical cleaning – The circulation of a water or oil-based chemical – is practiced around the industry with varying procedures and degrees of success. This method is equivalent to hydroblasting for cleaning effectiveness, but usually less effective because adequate procedures are not followed. You can expect a cleaning effectiveness anywhere between 30-85% based on the cleaning procedure. One benefit of this method is that the circulation is carried out in-situ, that is, it doesn’t require opening up the heat exchanger. Another is that multiple heat exchangers can be hooked-up to the circulation simultaneously, so the overall time and labor is reduced. With multiple heat exchangers, the cost is equivalent to hydroblasting on a per heat exchanger basis.

Thermal cleaning – Thermally decomposing organic material releasing pyrolysis gasses and leaving behind a coke-like residue – can be up to 100% effective, if the foulant is mostly organic. This method requires the insertion of the tube bundle into a high temperature oven. The reference below highlights the high effectiveness, safety, and low water consumption of the thermal cleaning method.

Click to View:

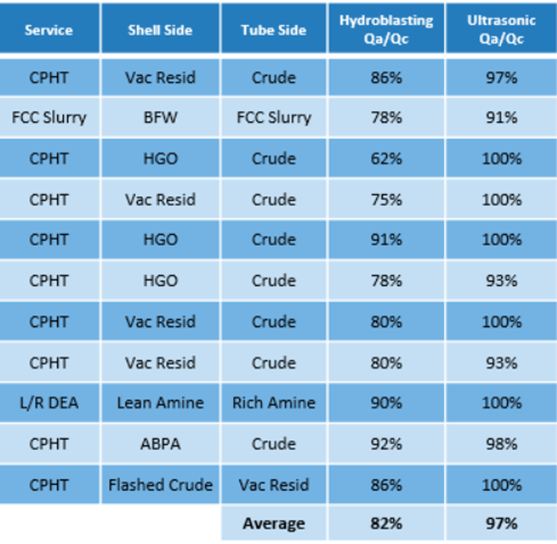

Ultrasonic cleaning – Immersion of the tube bundle in a water bath where ultrasonic waves form cavitation bubbles and impact the surface to remove deposits – has proven to be near 100% effective in cleaning both organic and inorganic fouling. The bath can have a chemistry to dissolve the deposits or hold them in suspension and make them easy to remove. The high effectiveness, safety, low water consumption, and overall low cost of this method is highlighted in the two references below. The table, based on analysis of actual operating data, shows the roughly 15% average improvement in cleanliness compared to hydroblasting. It shows the ratio of the actual heat duty right after cleaning (Qa) to what should be expected from a clean heat exchanger (Qc), for eleven actual cases from oil refining.

Click to View:

- Understanding The Value Of Cleaning – Gains From The Use Of Ultrasonic Cleaning

- Taking Safety To The Max : Eliminating Hydroblasting Risk

Data courtesy of Clean As New, www.cleanasnew.com

Shown below is a qualitative representation of the cost and effectiveness of three cleaning methods I have experienced.. In summary, chemical cleaning has a wide range of cost and effectiveness; Hydroblasting is about 85% effective with costs varying mainly based on location; and Ultrasonic cleaning gives the best cleaning at costs similar to Hydroblasting or cheaper.