How Clean Is Your Cleaned Heat Exchanger?

Heat exchangers foul so we clean them, put them back in service, and move on. But have you ever wondered whether the cleaned heat exchanger is actually delivering clean performance? Have you evaluated the heat duty right after cleaning to see whether it is what it should be? Chances are you haven’t, for a multiple of reasons such as: the heat duty now is higher than before cleaning so you are satisfied, it is not of high importance to have 100% cleanliness, or there is nothing you can do about it now. But if you did an evaluation, you’d find that most of the time the cleaned heat exchanger is delivering only about 85% of what should be the clean heat duty.

For critical heat exchangers which impact process performance or energy consumption, that extra 15% could translate to a large cost impact. So, what can you do about it? The foremost thing to consider is the cleaning method – is it the best, optimum, most cost-effective for a given heat exchanger?

The age-old cleaning method is hydroblasting – the use of high pressure water jets to force fouling off both the inside and outside surfaces of tubes. This process is labor intensive and an HSE risk unless robotic cleaning is used. The method depends on labor, so it can be low cost in some parts of the world but very high in others. The effectiveness of this method is around 85%.

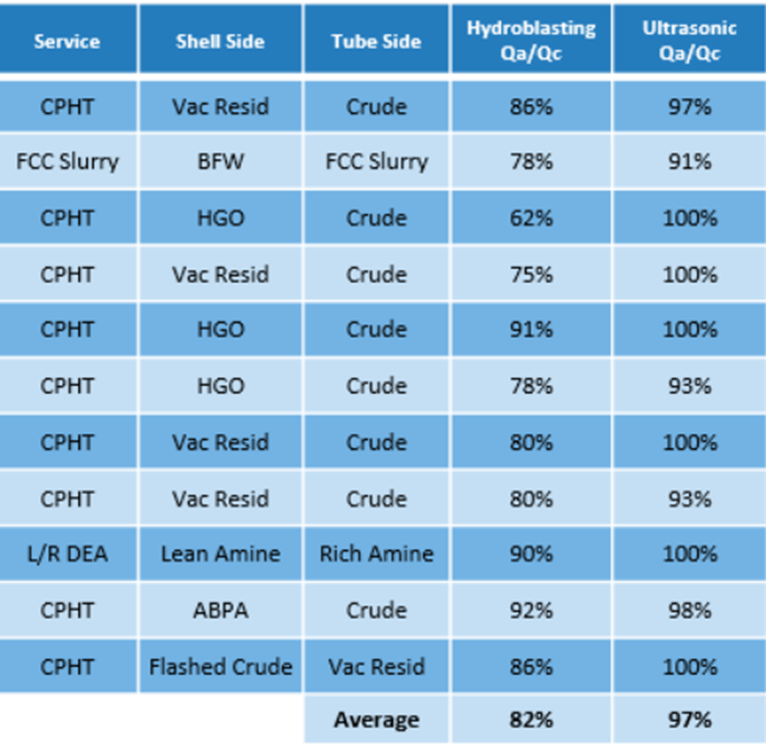

Contrast that with the method of ultrasonic cleaning, where the tube bundle (or sometimes shell + bundle) is immersed in a water bath and millions of microscopic bubbles impart energy to the tube surface and dislodge fouling. This method can be augmented by using a chemical in the bath to dissolve some of the foulant, and by pre and post hydroblasting with robotic cleaners. Ultrasonic cleaning will get heat exchangers cleaned back to near 100%, as shown in the table below. It shows the ratio of the actual heat duty right after cleaning (Qa) to what should be expected from a clean heat exchanger (Qc), for eleven actual cases from oil refining. The average cleanliness from ultrasonic cleaning is 15% higher with many achieving 100%.

The cost of ultrasonic cleaning could appear to be higher than hydroblasting in locations where labor rates are low if only the cleaning part is considered. But if all costs are included (field work to disassemble and assemble the heat exchanger, disposal of waste water, number of personnel involved in the cleaning process, safety of involved personnel) this method can prove to be cheaper and faster.

Two other methods can provide better or worse cleaning compared to hydroblasting – chemical cleaning and thermal cleaning. For a description of all the methods and their relative merits and costs, see the related article Comparison of Heat Exchanger Cleaning Methods

Data courtesy of Clean As New, www.cleanasnew.com

Becht can help you evaluate and optimize the cleaning of your heat exchanger.