Case Study – Coker Tower Bottoms Pump Failures

Pumps were experiencing repeated catastrophic thrust bearing failures upon start up after turnaround. These pump failures were occurring every 2 – 4 days. The electric motor driven pump was failing at a higher rate than the steam driven pump.

It was determined that the pumps were experiencing cavitation based on tower level swings and feed composition. There was also another feed from another unit to the pumps entering just before the suction flange that was a lighter product than the tower bottoms. This flow was uncontrolled and increased periodically post-turnaround. Excessive flow in this line combined with tower level swings caused the pumps to cavitate.

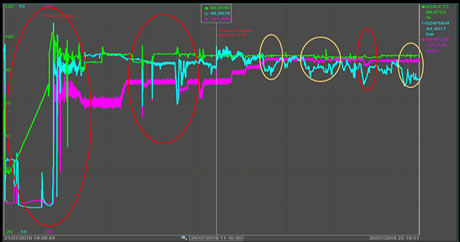

Becht made observations regarding swings in the operation of the tower, varying feed properties, NPSH for the pumps, differences in the pump strainer configuration, and design changes in the tower. Cavitation events (red circles in graphic) were noted. While the pump was running at constant speed and a constant flow, a change in the fluid relative density changes the discharge pressure (gold circles in graphic).

Becht recommended to maintain a high tower bottoms level to maximize pump NPSH, revisit the design changes made to the tower standpipe during the turnaround, revise the pump strainer on the electric motor driven pump to minimize pressure loss, and perform an operational study of the coker tower and related units to maintain a constant feed composition to the pumps.

Contact