Coke Drum Replacement

Coke Drum Skirt Replacement – No Downtime

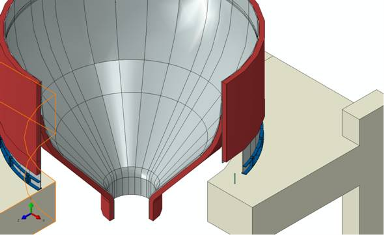

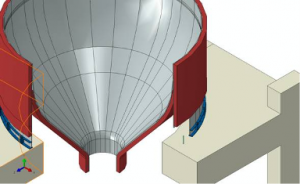

A major refinery in the Middle East requested Becht Engineering to evaluate the problem of their coke drums walking and tilting, and the baseplate/skirt/anchor bolts corroding. After an initial site visit by Trevor Seipp, Division Manager of Becht Engineering Canada Ltd., we determined that the lower portion of the skirt as well as the entire baseplate needs to be replaced for all eight coke drums. In addition, some of the coke drums needed to be re-leveled, and all needed to have shims and slide plates installed. Finally, all of the anchor bolts need to be replaced. And all of this needs to be done without any downtime. Building on the success of our world’s first in Texas, Becht Engineering developed a window methodology to complete the work whereby after we temporarily jack and re-level the drums and place them on temporary shims and slide plates, entire windows of the skirt (~1m x 1m) would be cut out and replaced with new material. While the window is cut out, however, we will have excellent access to the concrete deck to enact the anchor bolt replacement. What will make this project especially challenging is that all of this work needs to be completed while the drum remains in operation. Plus, there are 24 windows per drum and eight drums. All of this work needs to be developed using first-class engineering skills. Since the internal pressure, high temperature, and widely fluctuating weight due to the hydrocarbons, coke, and quench water all have to be evaluated during the repair process, Becht Engineering applied its expertise in finite element analysis (FEA) to the task. Our analysts are among the best in the business, and have performed evaluations on some of the most challenging problems.

A major refinery in the Middle East requested Becht Engineering to evaluate the problem of their coke drums walking and tilting, and the baseplate/skirt/anchor bolts corroding. After an initial site visit by Trevor Seipp, Division Manager of Becht Engineering Canada Ltd., we determined that the lower portion of the skirt as well as the entire baseplate needs to be replaced for all eight coke drums. In addition, some of the coke drums needed to be re-leveled, and all needed to have shims and slide plates installed. Finally, all of the anchor bolts need to be replaced. And all of this needs to be done without any downtime. Building on the success of our world’s first in Texas, Becht Engineering developed a window methodology to complete the work whereby after we temporarily jack and re-level the drums and place them on temporary shims and slide plates, entire windows of the skirt (~1m x 1m) would be cut out and replaced with new material. While the window is cut out, however, we will have excellent access to the concrete deck to enact the anchor bolt replacement. What will make this project especially challenging is that all of this work needs to be completed while the drum remains in operation. Plus, there are 24 windows per drum and eight drums. All of this work needs to be developed using first-class engineering skills. Since the internal pressure, high temperature, and widely fluctuating weight due to the hydrocarbons, coke, and quench water all have to be evaluated during the repair process, Becht Engineering applied its expertise in finite element analysis (FEA) to the task. Our analysts are among the best in the business, and have performed evaluations on some of the most challenging problems.