Corrosion – Risk-Based Inspection (RBI) Program

Focus on Corrosion – A Refinery-Wide Risk-Based Inspection (RBI) Program

Becht Engineering has completed development of a Refinery-wide Risk Based Inspection Program (RBI) at a Caribbean Refinery with a focus on corrosion damage mechanisms. The Refinery has observed accelerated corrosion in recent years, resulting in a higher than expected equipment replacement rate and commissioned the study in order to develop a plan to mitigate the corrosion.

Becht Engineering has completed development of a Refinery-wide Risk Based Inspection Program (RBI) at a Caribbean Refinery with a focus on corrosion damage mechanisms. The Refinery has observed accelerated corrosion in recent years, resulting in a higher than expected equipment replacement rate and commissioned the study in order to develop a plan to mitigate the corrosion.

Becht used its proprietary Risk-Based Equipment Reliability Planning work process which is embedded in the our software program STIER© (Strategy Tool for Improving Equipment Reliability) to develop the Risk-based Inspection and Maintenance Plan to address corrosion-related failure scenarios for fixed equipment, rotating equipment and piping circuits. Our work process is compliant with API RP 580, Risk-Based Inspection and ASME PCC-3-2007 Inspection Planning Using Risk-Based Methods.

The subject matter expert (SME) based approach was employed to develop failure scenarios. Once the relevant equipment data were collected and loaded into STIER, a Senior Metallurgists, James McLaughlin, reviewed the information and pre-developed damage mechanisms and failure scenarios for each item. Becht also employed the advice of a Senior Furnace SME, Robert Dubil, to develop failure scenarios, and inspection and maintenance plans for the furnaces. The facilitation team for the RBI Work Process was Dr. Eileen Chant and James McLaughlin.

The Becht process evaluated Economic Risk independently from Safety, Health and Environmental (S/H/E) Risk. Process dictated that an unacceptable S/H/E risk be mitigated to an acceptable level, while business (economic) risks are mitigated only if cost-justified. The calculated business risk is based on the probability of failure, failure consequence cost, probability of lost production, cost of lost production as well as other inputs for the failure scenario under consideration. The basis for task acceptance for mitigation of business risk is the Benefit-to-Cost Ratio (BCR) which is calculated as the benefit of mitigation (the difference between the unmitigated economic risk and the mitigated economic risk) divided by the cost of the proposed mitigation task.

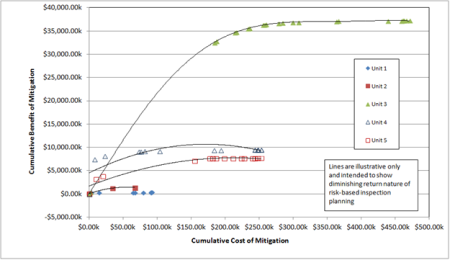

Approximately 200 fixed equipment, rotating equipment and piping items were assessed. The diminishing return nature of inspection and maintenance expenditures is illustrated in the figure. Each data point represents an inspection plan, and the figure shows a plot of the cumulative economic benefit of mitigation versus the cumulative expense of mitigation (task costs). The plot is ordered, from left to right, from the highest to the lowest BCR. This information is included with the results of all our RBI studies, allows plants to effectively manage maintenance and inspection budgets while minimizing business risk.

In addition to producing risk-based inspection plans on every assessed equipment item which correlates task implementation to risk reduction, our team developed a list of specific recommendations on a variety of issues. These recommendations included:

- Improved recordkeeping and inspection data management,

- Mitigation of water carryover in an overhead line which was causing accelerated corrosion in multiple equipment items,

- Best practices for furnace maintenance,

- Specific materials upgrades,

- Individual equipment design reviews, and

- Review of chemical program for monitoring and corrosion control in specific circuits

The study identified $82.6 million in economic risk reduction that can be accomplished through about $2 million investments in accepted inspection and maintenance tasks. Additionally, full credit was not taken in the mitigation plan for implementation of the above recommendations; it is expected that the plant can further improve reliability and reduce corrosion rates once these tasks are fully executed.maintenance tasks.