Equipment Re-Rating

Equipment Re-Rating

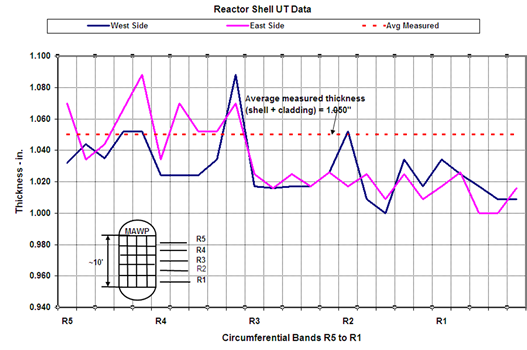

Becht has re-rated many pressure vessels and heat exchangers to higher design pressures and temperatures as well as de-rates to establish lower design pressures and temperatures as a consequence of corrosion or some other damage. As a part of any re-rate, an assessment of the vessels current condition is made looking for general corrosion and localized metal loss, environmental cracking, etc. Ultrasonic thickness (UT) measurement is used to check the vessel thickness vs. the minimum required by the code of construction. The figure shows a plot of typical thickness data obtained from a UT scan of a reactor vessel. Where thicknesses fall below the required (including the future corrosion allowance), a Fitness-for-Service assessment is conducted using the methods in API 579 – Fitness-for-Service.

Becht has re-rated many pressure vessels and heat exchangers to higher design pressures and temperatures as well as de-rates to establish lower design pressures and temperatures as a consequence of corrosion or some other damage. As a part of any re-rate, an assessment of the vessels current condition is made looking for general corrosion and localized metal loss, environmental cracking, etc. Ultrasonic thickness (UT) measurement is used to check the vessel thickness vs. the minimum required by the code of construction. The figure shows a plot of typical thickness data obtained from a UT scan of a reactor vessel. Where thicknesses fall below the required (including the future corrosion allowance), a Fitness-for-Service assessment is conducted using the methods in API 579 – Fitness-for-Service.

Often a client may want to increase the design pressure of a vessel by using the higher allowable stresses permitted by the 1998 Edition of ASME Code Section VIII, Div.1. This is possible; however, the rules do not permit rerates for vessels built prior to the 1968 Code, and other rules contained in the 1998 Code must be followed, e.g., impact test requirements.

Becht has also conducted the analysis and the inspections necessary to bring a pressure vessel built to other Codes, non-ASME code stamped vessels and “used” vessel into a state. The requirements can vary by state. Becht has completed the application and technical requirements and submitted the application to the state for approval by the agency responsible for code and state regulations related to pressure vessels.

Contact