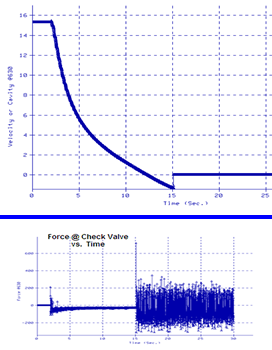

What is Bellows Pressure Thrust?

Pressure thrust is present in all pressurized piping systems. It is simply the gage pressure times the inside area of the pipe. It acts at changes in direction, such as elbows, and at changes in pipe cross section, such as reducers. Pressure thrust is normally carried as an axial load by the pipe. However, inclusion […]