Five Keys to a Cost-Effective Repair/Modification Package for Tanks-Vessels-Piping

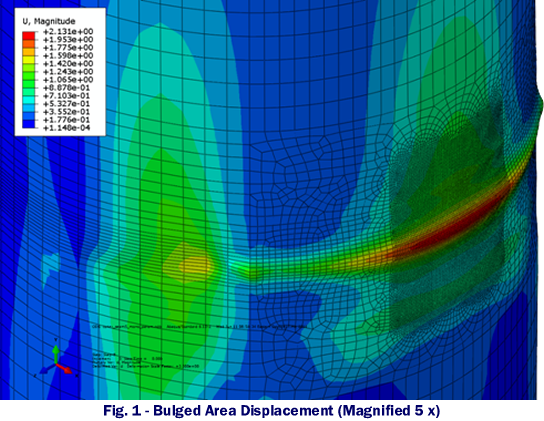

: Process: Does the repair change the process chemistries, physics (fluid phase), and thermo-hydraulics (flow rates, pressures, temperatures)? Does the modification change the control room indications and the operating envelopes? Material: Are the selected metallic materials (base metal and welds) and non-metallic materials (gaskets, packings, etc.) compatible with the existing materials, with the environment, and […]