A Novel Nondestructive Technique for Detecting and Sizing Carburization Damage in Heater Tubes

Fired Heaters come in many types and configurations: catalytic reformers, crude heaters, visbreakers, vacuum heaters, coker heaters, etc; and many are prone to carburization damage (i.e. residual carbon diffusing into the tube material, causing damage or even failure).

Many refineries today use delayed coking processes to upgrade their crude product. This process includes the use of fired heaters operating at high pressures and temperatures. In a carburizing environment this can lead to coke residue buildup at the tube ID followed by carbon diffusing into the tube wall, degrading the metallurgical structure of the tube.

Until recently, the only reliable method of testing for carburization damage was to cut out tube sections, test by metallurgical examination, then weld back in (and repeat as necessary until unaffected tubes are found); a slow and costly approach. Now, a relatively new nondestructive technique application, developed by Sonomatic, and in use worldwide, negates the need to repeatedly cut and weld tube sections to retrieve samples for metallurgical examination.

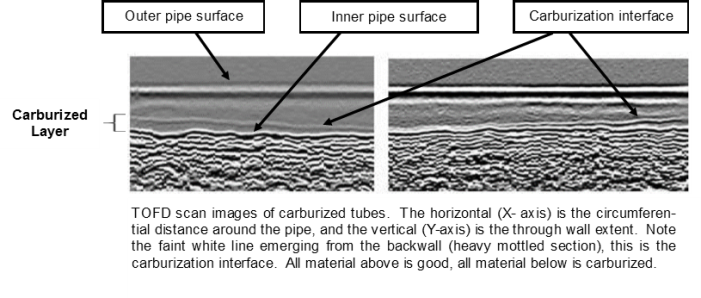

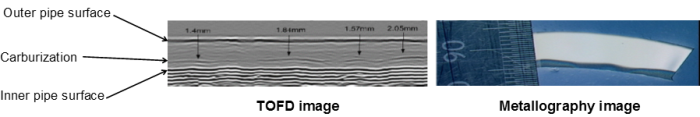

The technique uses ultrasound, or more specifically, a non-standard Time-of-Flight-Diffraction (TOFD) ultrasonic inspection method, to create thru-wall images of the tubes and identify the boundary between good (non-carburized) and bad (carburized) material. This technique is capable of detection and quantification of carburization damage in 2-9% Chrome alloy ferritic tubes.

This technique requires strict adherence to specific inspection protocols. The interface between carburized and non-carburized material can be missed if the controls are not followed. However when properly applied, the technique can detect the thru-wall extent of carburization to within 0.5mm, and has been verified with destructive testing and metallography in numerous trials.

The inspection results have been shown to fall well within the tolerances required for a critical assessment evaluation, and this technique is currently being used at refineries and process plants world-wide, providing accurate, reliable heater tube condition assessments.

Peter Conlin ISO 9712 Level 3