Bad Actor Elimination Through Cooperation, Collaboration and Trust

Recently published in the Inspectioneering Journal.

Two heads are better than one, as the old saying goes. However, this adage only works if the two heads trust each other and are interested in working together to solve a problem. Elimination of chronic bad actors in hydrocarbon processing facilities is much more important than egos, silos, and failure to share information. Unfortunately, this can be a common problem in some organizations. We have even observed in some organizations where conflict is encouraged and maintenance of “dynamic tension” is the way of life. It’s difficult to establish a sense of trust in this environment.

It is very difficult to solve problems in a silo type of environment or where there is a lack of trust. Complex problems require collaboration between process, operations, maintenance, inspection, and engineering. If this does not happen, the plant will remain in a failure/firefighting mode that is costly and can ultimately result in a major accident or injury. It can also prevent a plant from truly optimizing performance because people and organizations are not working together.

In most plants, the 80/20 or 90/10 rule applies: 10 to 20 percent of the equipment causes 80 to 90 percent of the losses. In order to root out bad actors, both data analysis and collaboration are required. In general, the operations personnel are the owners of the equipment and the operators are the first line of defense, observing equipment performance on a continuous basis. It’s important that the operator maintains constant vigilance over the equipment using visual observation, distributed control system (DCS) information, and hand-held data collectors. When issues such as leaks, odd sounds, excessive vibration, etc. are noted, or operation is outside the plant operating window, it is incumbent on operations to bring in other resources from engineering, maintenance, and inspection to evaluate the issue. Unfortunately, changes in daily operations and process conditions are not always communicated effectively. Oftentimes these issues cause repeat failures and, through Pareto analysis, can be grouped by frequency, cost, and outage duration. This analysis will surface a collection of “Top 10 Bad Actors.” At this point a critical decision is needed. Are we going to work together to gather data and fix the problem permanently or just talk about it in our silos?

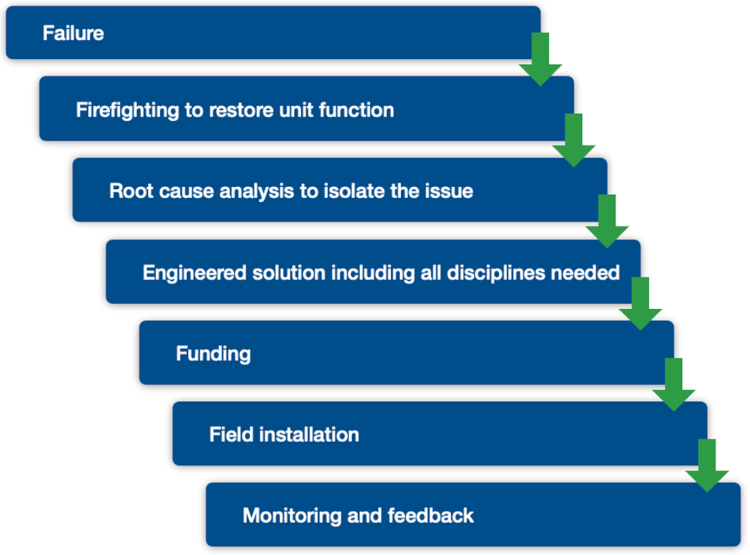

Successful organizations attack the problem in a methodical way as shown below.

However, if this process is held up or poorly executed before the Field Installation step, the exercise is futile, and the problems will return over and over. The secret to making this process work is a strong sense of teamwork and trust between organizations. Trust in any relationship is earned and is fragile. Organizations must have a sense of trust across the plant and at the corporate level. This is a powerful system if it can be achieved.

I worked in an organization where the mantra was “compete externally, collaborate internally.” While this was quite different from many organizations, it was driven from the top down and people were held accountable. As a result, a high level of trust, collaboration, resource sharing, and breaking down conventional barriers was achieved. By bringing this concept and resources together, world scale plants achieved outstanding reliability, reduced costs, and an environment that facilitated an enjoyable place to work, resource sharing, safe operations, and profits that benefited all employees. Trust is key, as is the sharing of lessons learned across all sites, and these must be practiced at all levels. Hopefully your organization can and does practice working together across process, operations, maintenance, inspection, and reliability to eliminate chronic problems and to assure everyone understands the impact of changes so they can be mitigated BEFORE they cause a problem.

Like to learn more? Contact Becht to speak with an expert.