Beyond-Design-Basis Events

Following the 2011 tsunami and accident at Fukushima-Daiichi in Japan, the nuclear power industry has embarked on a significant effort to evaluate the effect of beyond-design-basis (BDB) events, particularly earthquakes, tsunamis, and floods, on the safety of nuclear power plants.

What are BDBs? Beyond-design-basis (BDB) events (sometimes also labeled BDBE) are accident sequences that have such a low probability of occurrence that they were not part of the original plant design. BDB events can be subdivided into two general categories: Internal events, and external events.

- Internal events include accidents or malfunctions such as multiple spurious failures (rather than the classic single-failure criterion), internal fires, ejected missiles larger than considered in design, chemical reactions and possibly explosions, multiple operator errors, etc.

- External events can in turn be subdivided into two categories: Man-made, and natural phenomena hazards (NPHs). Man-made events could be accidental or malevolent. BDB NPHs are natural phenomena of a magnitude larger than the design basis. A classic example would be an earthquake (a) larger than the original design safe shutdown earthquake (SSE), or (b) of a different frequency content.

There are several types of beyond-design-basis (BDB) natural phenomena hazards (NPHs): Seismic, tsunami, external flood, extreme winds and tornadoes, lightning, extreme cold and icing, extreme heat and drought, large ash fall, and external fire.

BDB and Risk. The study of BDB events is a logical application of risk-informed engineering. While we design nuclear plants for large, unlikely events (say a safe-shutdown earthquake SSE or a design-basis flood), it is valid to ask ourselves whether another event, say 20% larger, would cause significant damage. In other words, is there is a cliff passed the design-basis event? Because risk is the consideration of likelihood and consequence, when the consequence is as significant as a large release of radioactivity, then even very remote events, those with very low likelihood, must be probed.

What SSCs are involved? Practically speaking, any structure, system, or component (SSC) that plays a role in the safe operation, safe shutdown, post-shutdown cooling, and containment of a plant is part of the BDB scope. This means:

- The containment structures, the concrete and steel structures, and the control room

- The safety-related mechanical distribution systems (piping, tubing, and HVAC ducts)

- The safety-related mechanical equipment (fixed: vessels and tanks; and active: pumps, compressors, fans)

- The safety-related electrical distribution systems (conduit and cable trays)

- The emergency electrical equipment (generators, batteries, motor control centers, switchgear, instrument panels, etc.)

For example, there has recently been a special emphasis on the performance of spent fuel pools in nuclear power plants, in case of a BDB, in particular whether the stored fuel would remain cooled in case of a BDB accident (NRC Generic Safety Issue 82 “Beyond Design Basis Accidents in Spent Fuel Pools”, NUREG-0933 Supplements 1-34.)

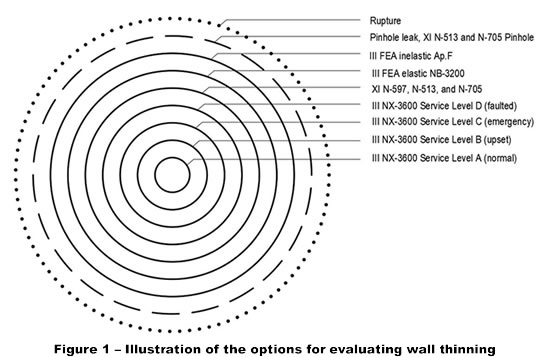

Which approach to BDB assessments? There are basically two methods to approach the analysis of BDB events: A deterministic method, and a probabilistic method.

- The deterministic method consists in quantifying the demand imposed by the BDB event (typically in terms of loads, stresses, motions, etc.) and comparing it to the capacity of the SSC. Engineers are quite familiar with this approach in the context of design, where the demand is calculated on a conservative basis (over-estimated demands), and the capacity is set by codes and standards, including design margins (under-estimated capacities.) Now, when analyzing BDBs, these conservative assumptions are trimmed-down to understand more precisely the true demand-to-capacity ratio, and therefore to foresee the true failure mode and its potential consequence.

- The probabilistic approach differs from the deterministic approach in several ways. In particular, the probabilistic approach relies on the following studies:

– A system risk analysis (event trees and fault trees) which identifies the critical SSCs that will be relied upon for safe shutdown and containment.

– A whole range of BDB event magnitudes (probabilistic demands) are developed for the given site, each with its probability of occurrence.

– The capacity of the SSCs is developed in the form of fragilities (probabilistic capacities, conditional probability of failure given a demand magnitude).

The probabilistic approach is being applied in the on-going seismic probabilistic risk analysis (SPRA) in the US nuclear industry, through EPRI’s “Seismic Evaluation Guidance: Screening, Prioritization and Implementation Details (SPID) for the Resolution of Fukushima Near-Term Task Force Recommendation 2.1: Seismic”. In this case, for each site, the demand is in the form of earthquake hazard curves which cover a range of magnitudes (from small with a high probability, to very large with a very low probability). The capacities are expressed in terms of fragilities, which are conditional probabilities of failures given an earthquake magnitude parameter, such as peak ground acceleration.

Prevention of Damage and Return to Service? The nuclear power industry is addressing BDBs not only to prevent accidents in case of BDB events, but also to set in place the hardware and procedures that would limit damage, and would allow for a return of the plant to service after a BDB event.

The industry and the regulators have asked themselves what should be the inspections, tests, analyses, and repairs required following a BDB? For example, what to do following a flood that would wet or even submerge SSCs, after the plant has been safely shutdown, the flood has receded, and equipment has been dried? EPRI has already completed several studies on a similar question related to actions following a seismic event (EPRI NP-5930, EPRI NP-6695, 1014099, etc.) and the NRC has addressed “Pre-earthquake Planning and Immediate Nuclear Power Plant Operator Post-Earthquake Actions” (NUREG 1.166).