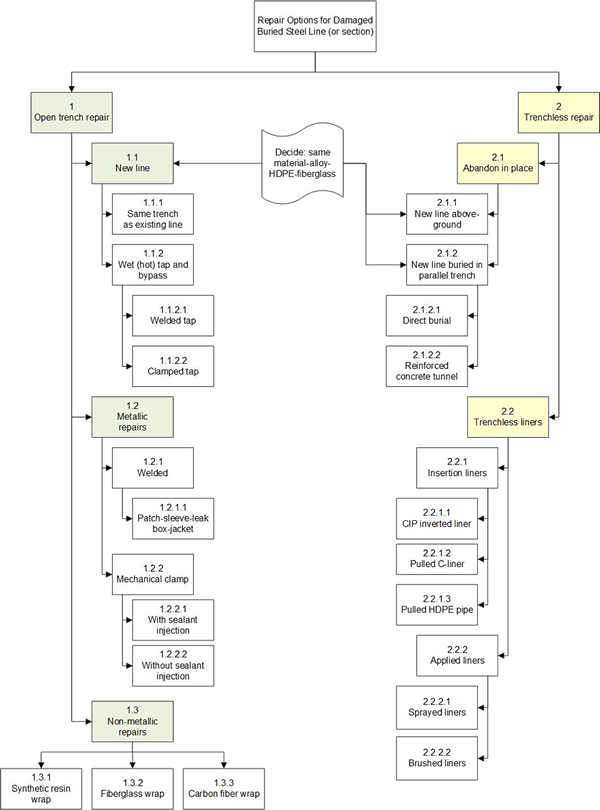

Roadmap For Repair of Buried Pipe

The repair of a corroded, damaged, or leaking buried pipe should be approached in a well-structured manner. Here is a roadmap to the repair options for buried steel pipes, with the corresponding brief commentary.

- 1. Open trench repair

- 1.1 New line, replacing the existing line (or segment). Determine whether to use the same material, or a higher alloy, or HDPE, or fiberglass for the new pipe.

- 1.1.1 Same trench as existing line, either cut-out and replace the old line, or abandon in-place the old line and place the new line next to or above the abandoned existing line. Caution with new line near old one if there is cathodic protection.

- 1.1.2 Wet (hot) tap and bypass, installing a new bypass either above ground or buried.

- 1.1.2.1 Welded tap, if the old line has sufficient remaining wall to be weldable.

- 1.1.2.2 Clamped tap, using a bolted full-encirclement clamp with a nozzle, instead of a welded wet (hot) tap.

- 1.2 Metallic repairs

- 1.2.1 Welded repairs include welded patch (PCC-2 Article 212), full-encirclement sleeve (PCC-2 Article 206), leak box (PCC-2 Article 204), or encapsulating the existing pipe inside a metallic jacket pipe (creating a double-containment pipe).

- 1.2.2 Mechanical clamp (PCC-2 Article 306)

- 1.2.2.1 With sealant injection.

- 1.2.2.2 Without sealant injection.

- 1.3 Non-metallic repairs

- 1.3.1 Synthetic unreinforced resin fiber, for ambient temperature low pressure applications.

- 1.3.2 Fiberglass wrap, water activated, typically for near ambient temperature and pressures below approximately 200 psi. Surface finish of the existing pipe prior to wrap per manufacturer.

- 1.3.3 Carbon fiber wrap for higher pressures and temperatures. Surface finish of the existing pipe prior to wrap per manufacturer.

- 1.1 New line, replacing the existing line (or segment). Determine whether to use the same material, or a higher alloy, or HDPE, or fiberglass for the new pipe.

- 2 Trenchless repair

- 2.1 Abandon in-place, no need to open the existing trench to reach the existing pipe.

- 2.1.1 New line above ground: Determine whether to use the same material, or a higher alloy, or HDPE, or fiberglass for the new pipe. If the new pipe is HDPE or fiberglass aboveground there will be a need for more supports than if metallic.

- 2.1.2 New line buried, generally in a parallel trench.

- 2.1.2.1 Direct burial, filling the trench with soil or with hydrophobic fill if soil-side corrosion in wet soil, or CLSM.

- 2.1.2.2 Construction of a reinforced concrete tunnel, with covers and drainage to permit future access to the new underground line.

- 2.2 Trenchless liners

- 2.2.1 Insertion liners that form a pipe within a pipe (ASME PCC-2 Part 4).

- 2.2.1.1 Cured-in place inverted liner. It consists of a flexible felt or fiber-reinforced tube impregnated with resin, which is inverted and cured inside the existing damaged pipe.

- 2.2.1.2 Pulled C-liner (or U-liner), is typically a HDPE or polyurethane pipe that is flattened and bent into a u-shape (c-shape), strapped and shipped to the field. It is then pulles inside the existing pie and popped open by internal pressure.

- 2.2.1.3 Pulled HDPE pipe, of a size smaller than the existing pipe, if the smaller diameter (but smoother) pipe is acceptable hydraulically.

- 2.2.2 Applied liners (ASME Article 403).

- 2.2.2.1 Sprayed liners can be applied by pulling a wheel-mounted rotating sprayer, after the existing pipe ID has been cleaned and prepared.

- 2.2.2.2 Brushed liner, if the existing pipe is sufficiently large to permit entry, cleaning, and brush or roller application of the repair compound.

- 2.2.1 Insertion liners that form a pipe within a pipe (ASME PCC-2 Part 4).

- 2.1 Abandon in-place, no need to open the existing trench to reach the existing pipe.

If you have a question relating to this blog, you may post a comment for the author at the bottom of this page. If you would like to submit an Information Request please click below: