Going Beyond Compliance: How Refineries Can Reduce GHG Emissions and Stay Competitive in a Low-Carbon Future

With contributing author Jessica Hofmann

The oil and gas industry alone, directly and indirectly, contributes to 42 per cent of global emissions. As a result, refineries worldwide, as part of the wider O&G value chain, are facing increasing pressure to reduce their greenhouse gas (GHG) emissions and align with climate-change goals set by regulators. Refineries are urged to define and implement a decarbonization strategy to reach climate-change goals set by regulators and are increasingly seeing a direct or indirect financial impact for failing to do so. This can range from direct carbon cost in any of the growing number of jurisdictions with a carbon cap-and-trade program, to increased cost of lending, as more banks apply their own emission reduction targets to their lending portfolio. However, reducing GHG emissions in refineries goes beyond addressing emissions from production processes.

What are the challenges in reducing GHG Emissions?

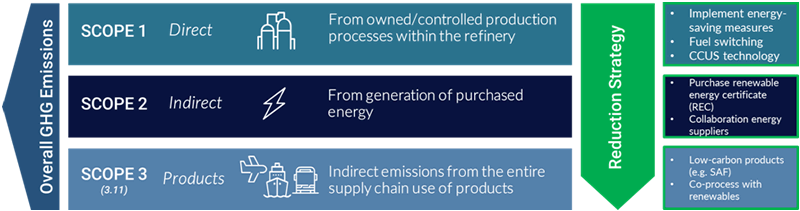

Reducing the full value chain GHG emissions in refineries requires addressing both direct and indirect emissions. It goes beyond production processes and encompasses indirect emissions from purchased energy and the entire supply chain. Operators must understand and comply with regulatory landscapes like the EU Emissions Trading System (ETS) while considering emissions across different scopes. This necessitates effective emissions management strategies and diligent monitoring across all emission scopes. The GHG Gas Protocol has defined the different emission scopes.

What are the different kinds of emission scopes as defined by the GHG protocol, and how can they be reduced?

Scope 1 GHG Emissions

Scope 1 emissions, arise directly from production processes inside battery limits. They represent the physical loss of CO2 and other GHG gases through furnace stacks, leaks and fugitive emissions, and controlled (where still allowed) or uncontrolled flaring. To reduce Scope 1 emissions, refineries can implement energy-saving measures like heat recovery systems, and equipment upgrades, and explore low-carbon alternatives to the fuel that they use, in particular replacing natural gas by RNG or installing on-site renewable energy systems such as the production of green hydrogen. It should be noted that a significant part of a refinery energy use comes from its own process fuels like fuel gas or fuel oil, and therefore the use of low carbon feedstocks, critical for Scope 3 as we shall see later, also has a positive impact on Scope 1 emissions.. Ultimately, a strategy which aims to make very deep reductions to a refinery’s Scope 1 emissions is likely to require some form of large-scale Carbon Capture, Utilization and Storage (CCUS) technology.

Scope 2 GHG Emissions

Scope 2 emissions are indirect emissions resulting from purchased energy. Scope 2 emissions can be reduced through various strategies, including purchasing renewable energy certificates (RECs) or collaborating with energy suppliers to switch to low-carbon energy sources. Scope 2 emissions are typically lower than Scope 1 and the refinery has less direct control since a 3rd party energy supplier is involved.

Scope 3 GHG Emissions

Scope 3 emissions encompass the indirect emissions of the entire supply chain, including production, transportation, and end-product use. For combustion products such as transport fuels or heating fuel, the end-use element (element 3.11) is in fact by far the largest impact of the entire supply chain, since all the carbon contained in the fuel itself is released to atmosphere during end-use combustion, Refineries can significantly reduce Scope 3.11 emissions – on an absolute basis or based on the Carbon Intensity (CI) per unit of energy – by developing low-carbon products such as sustainable aviation fuel (SAF) and renewable diesel, either by co-processing bio-feedstocks in refinery units or by investing in a stand-alone biofuel production unit co-located at the refinery. It should be noted that this latter option does not reduce the absolute level of emissions (in fact it directly adds to Scope 1 & 2 emissions) but will reduce the average CI of the product slate, by introducing a larger proportion of low carbon fuels in the total refinery output.

So, refineries must explore and employ practical strategies to measure, manage, and reduce GHG emissions across all emission scopes. As seen above, a range of options – each with its own implicit or explicit carbon cost – can be considered depending on a Company’s objectives and stated decarbonization targets. Of course, energy efficiency programs are always a good starting point, since they tend to be “good for all seasons” and deliver direct financial benefits before including any benefits from emission reductions. Production of low carbon fuels can also deliver strong returns, especially for markets where low carbon fuel regulations (such as the LCFS Low Carbon Fuels Standard in California or the REDII Renewable Energy Directive in the EU) provide a supportive price structure for these products. At the other end of the scale, technologies such as CCUS or the production of green hydrogen from electrolysis have a relatively high cost of carbon abatement and their adoption will progress more slowly, as these technologies mature, and their costs reduce. Meanwhile, they will only feature in the more ambitious decarbonization programs, or where special circumstances exist – such as specific regulatory or Government support.

What are the regulatory frameworks in the EU?

Refineries must comply with numerous regulations concerning GHG emissions, including the EU Emissions Trading System (ETS). The EU ETS was introduced by the Council in 2005 and is one of the key tools to reduce GHG emissions and one of the world’s largest carbon markets. The ETS is working by putting a cap on specific GHG intense industries and reducing the allowances year by year. Refineries are covered by the ETS for their Scope 1 & 2, and just recently in April 2023 the European Council adopted a new reform to the ETS, resulting in further and steeper emissions reduction targets. By 2030, the cap on emissions from sectors falling under the scope of the EU ETS is projected to reduce by 62% compared to the levels recorded in 2005.

This isn’t an isolated policy, since the California Cap-and-Trade program works in a very similar way by reducing allowances every year, and addresses approximately 80% of the State’s GHG emissions, according to the CARB (California Air Resource Board) website.

Ensuring compliance with these regulations necessitates effective emissions management strategies and thorough monitoring.

Why is accurate measurement and reporting essential?

An essential part of addressing and effectively managing emissions is to allow for accurate measurement, modelling & simulation of GHG emissions during refinery processes. The GHG Protocol is hereby a valuable accounting framework as it provides guidance and standards for the industry to quantify and report their emissions. Refineries can use tools such as mass balances and monitoring equipment to measure emissions accurately. Once emissions are measured, they can be managed through diverse strategies like setting emission reduction targets, implementing energy-saving measures, and investing in low-carbon technologies. Consistent, comparable, and reliable data is needed.

How can BECHT help in navigating the complexity?

Reducing GHG emissions across all scopes in refineries is undoubtedly a complex challenge, and managing emissions across Scopes 1, 2, and 3 can be a complex and daunting task, but we’re here to provide guidance and make it more manageable. Collaborating with an experienced consulting firm like BECHT will help refineries navigate the complexities of GHG emissions.

At BECHT, we specialize in assisting refineries in achieving their emission reduction targets while remaining cost-competitive and supporting the EU’s emissions reduction goals. Our experienced consulting team can help navigate the complexities of GHG emissions by analyzing your current upstream, midstream, and downstream emissions, setting targeted reduction strategies and providing guidance on effective measurements and employing state-of-the-art solutions. Together with you, we will establish a thorough GHG-reduction goal and plan.

By partnering with BECHT, refineries can access our expertise and industry knowledge to implement sustainable practices and contribute to a more environmentally friendly future.

Don’t let the challenges of GHG emissions hold your refinery back. Contact BECHT today and let us help you navigate the complexities, optimize your emissions management, and create a more sustainable and competitive future.