From the Top: Proactively Planning Different Crude Slates to Capture Margin Opportunity

The business need for working with opportunity crudes in refinery unit operations, an essential aspect of crude blending and crude slate planning, has meant that operators face substantial risk of corrosion damage in the crude distillation unit (CDU), vacuum distillation unit (VDU), and side stream piping. Using total acid number (TAN) and sulfur content in crudes as proxies for naphthenic acid and sulfidic corrosion in refinery crude unit operations has often led to conservative, cost-inefficient decision-making in terms of crude selection, crude processing, and unit metallurgy specifications. The refining industry has constantly sought, for reasons of improved economics and ROI, to move in the direction of processing heavier, high-sulfur, high-acid, opportunity crudes. Such a directional shift has been a consequence of depleting reserves and declining sweet crudes. Processing of low-cost opportunity crudes as an integral part of crude-slate planning and optimization has become imperative to improving refining margin.

Prediction modeling can be used to quantify naphthenic acid and sulfidic corrosion correlated with unit process and operating data. When combined with unit metallurgy, such a model can predict metal loss rates and remaining life for CDU/VDU piping exposed to hot oil conditions.

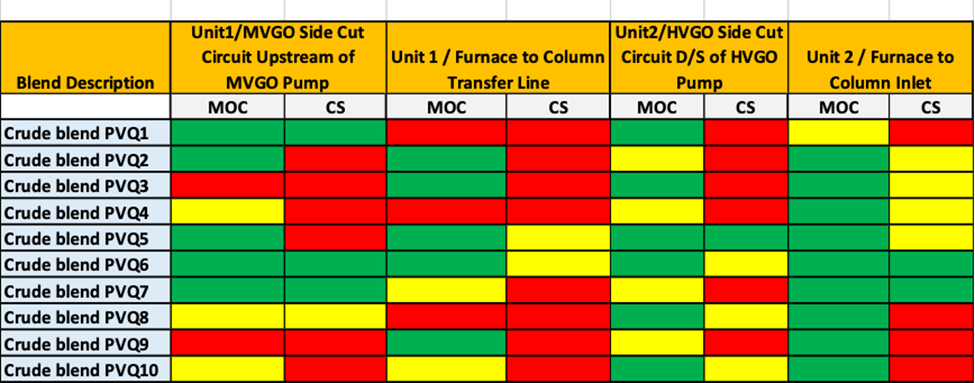

The ability to quantify corrosion for different crude fractions means that crude planners can assess the impact of different opportunity crude blends on unit piping corrosion prior to determining utilization of a given crude slate. This also gives planners the ability to mix and match corrosive and benign crude blends alternatively to achieve pre-set metal loss (based on design corrosion allowance) and reliability goals based on the visibility provided through the prediction model. Such crude processing flexibility has significant implications for extensive cost savings. In one simulated example, the ability to utilize a Venezuelan DCO cargo (600 Kb/cargo) of higher TAN, corrosive crude blend (higher corrosion rates) in tandem with the normal crude diet (lower corrosion rates) was shown to achieve cost savings of $1.8M per DCO cargo while ensuring thickness loss within limits throughout the operations. Figure 1 below demonstrates how such a prediction model may be used to identify optimal blends for processing.

Figure 1. Identifying optimal blends for processing

Based on the user data for the process environment and piping systems, such a framework has the potential to predict corrosion rates and offer a number of corrosivity-related insights, including:

- Comparison of corrosion rates for commonly used materials of construction

- The ability to track cumulative metal loss, instantaneous corrosion rate on a time scale as well as the average corrosion rate

- Quantification of batch crude operations over time to assess optimal sequencing of crude blends and the ability to incorporate the effect of any protective corrosion product (FeS) barrier layer on subsequent crudes in the sequence

Predictive modeling frameworks such as the one proposed herein represent a new evolution in corrosion prediction/modeling technology designed to provide refiners enhanced asset integrity, optimized throughput and blend management, and flexibility to work with opportunity crudes leading to improved profitability.