The Best Path To Maintenance Cost Reduction

While most organizations acknowledge a link between maintenance and reliability, the maintenance and reliability departments are often held within separate organizations at both site and corporate levels. They typically have separate goals and work separately to achieve these goals. One of the key measurements of the maintenance department is the maintenance budget while a key measurement of the reliability department is plant availability.

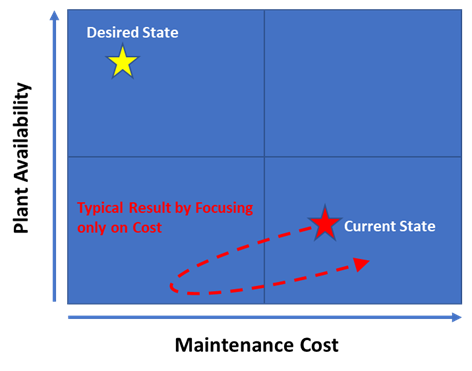

Historically, there have been various approaches to reducing maintenance costs. The first is to focus on the maintenance budget and reduce spend. In this approach, design improvements and preventive maintenance are typically seen as discretionary spend and are the first targets of budget reduction. The short-term effect is a reduced maintenance cost. The mid-term effect is a reduced plant availability as the impact of reduced preventive maintenance is felt. In the long-term, maintenance cost often exceeds the original baseline maintenance cost as the facility deals with the consequence of reduced equipment reliability.

Historically, there have been various approaches to reducing maintenance costs. The first is to focus on the maintenance budget and reduce spend. In this approach, design improvements and preventive maintenance are typically seen as discretionary spend and are the first targets of budget reduction. The short-term effect is a reduced maintenance cost. The mid-term effect is a reduced plant availability as the impact of reduced preventive maintenance is felt. In the long-term, maintenance cost often exceeds the original baseline maintenance cost as the facility deals with the consequence of reduced equipment reliability.

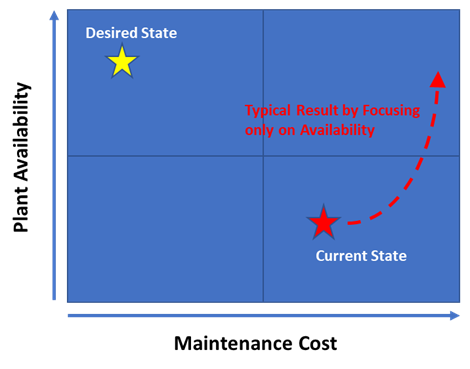

Benchmarking shows that highly reliable sites have the lowest maintenance costs. This can lead to an approach which focuses solely  on availability. Unfortunately, a focus on availability without focusing on equipment reliability can dramatically increase maintenance cost. Sparing a pump with poor reliability improves availability if the main pump can be repaired before the spare fails. However, equipment reliability has not been improved and the cost of the improved availability includes the cost of the spare, the additional repair costs of both pumps and the additional labor force required for the increase in maintenance.

on availability. Unfortunately, a focus on availability without focusing on equipment reliability can dramatically increase maintenance cost. Sparing a pump with poor reliability improves availability if the main pump can be repaired before the spare fails. However, equipment reliability has not been improved and the cost of the improved availability includes the cost of the spare, the additional repair costs of both pumps and the additional labor force required for the increase in maintenance.

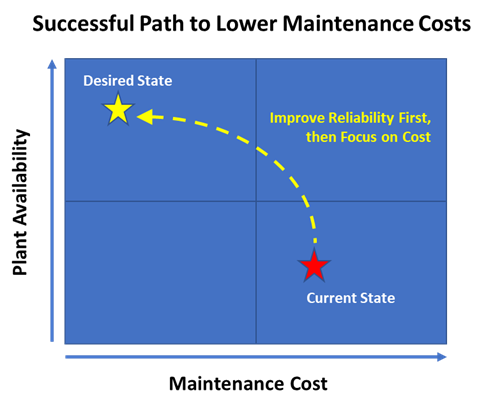

Benchmarking also shows us that 60% of maintenance value (measured by maintenance cost) comes from the demand for maintenance. This includes the design of the equipment, the way the equipment is operated and the maintenance of the equipment. An improvement in the reliability of equipment will result in a reduction of cost for the unreliability of the equipment.

Benchmarking also shows us that 60% of maintenance value (measured by maintenance cost) comes from the demand for maintenance. This includes the design of the equipment, the way the equipment is operated and the maintenance of the equipment. An improvement in the reliability of equipment will result in a reduction of cost for the unreliability of the equipment.

A maintenance department that is looking to improve maintenance cost should partner with the reliability department and focus on reliability improvements with the goal of reducing the cost of unreliability. When this is done correctly, you get the results shown in the figure to the left.

If you have trouble envisioning how to get started, Becht has an experienced team of maintenance and reliability professionals who can help with assessing your situation and helping you implement the path forward. Visit Becht’s Turnaround section or contact us by clicking below:

Like to learn more about lowering your maintenance costs while increasing reliability? Contact Becht to speak with an expert.