Why Doesn’t a Great Maintenance Process Equal Great Results? (Part 2)

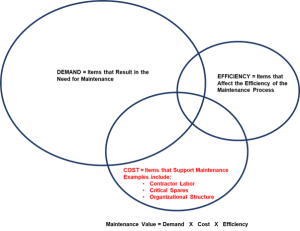

In Part 1 we observed that some of the best results come from organizations with poor maintenance work processes and some organizations with a great work process have poor results. It was also noted that the maintenance work process itself only accounts for 10% to 20% of the total maintenance value. In Part 2 we look at Contractor Labor Management which is an element of the Cost driver.

The Cost driver is made of those elements that are necessary and support Maintenance Execution. From Benchmarking, we know that the Cost driver accounts for 20% – 30% of Maintenance Value. It includes items like Contractor Labor, Critical Spares and Organizational Structure. Contractor labor is a significant portion of this driver. Here are some questions that can be asked to determine if there is an opportunity to improve a site’s contractor labor management:

The Cost driver is made of those elements that are necessary and support Maintenance Execution. From Benchmarking, we know that the Cost driver accounts for 20% – 30% of Maintenance Value. It includes items like Contractor Labor, Critical Spares and Organizational Structure. Contractor labor is a significant portion of this driver. Here are some questions that can be asked to determine if there is an opportunity to improve a site’s contractor labor management:

WHAT METHODOLOGY DOES THE SITE USE TO CONTROL THE NUMBER OF CONTRACTORS THAT ARE ON THE SITE?

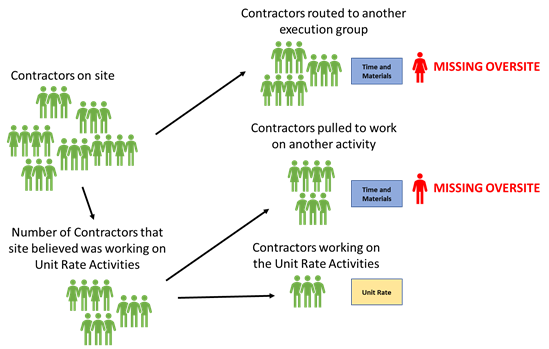

In a recent site visit, there was an observation that there was an extremely high number of contractors on-site and there wasn’t an activity like a pit-stop or turnaround occurring. The site had Unit Rate contracts with the on-site maintenance contractors. Because of this, there was a belief that there was no need to monitor the number of contractors that were on site. A quick look into the contracts showed that not all the site’s execution groups (routine maintenance, projects and turnarounds) used the same Unit Rate contracts. Additionally, even for the group using the Unit Rate contract, about 40% of the work was being done on a Time and Materials basis due to the amount of work that was not defined by the unit rates.

In a recent site visit, there was an observation that there was an extremely high number of contractors on-site and there wasn’t an activity like a pit-stop or turnaround occurring. The site had Unit Rate contracts with the on-site maintenance contractors. Because of this, there was a belief that there was no need to monitor the number of contractors that were on site. A quick look into the contracts showed that not all the site’s execution groups (routine maintenance, projects and turnarounds) used the same Unit Rate contracts. Additionally, even for the group using the Unit Rate contract, about 40% of the work was being done on a Time and Materials basis due to the amount of work that was not defined by the unit rates.

For an onshore facility, a general rule-of-thumb is that Labor accounts for approximately 70% of Routine Maintenance Cost. Understanding the number of contractors that are on-site and why they are there is critical to ensuring that costs stay on budget.

DOES THE MAINTENANCE TEAM UNDERSTAND WHAT TYPES OF CONTRACTS ARE IN PLACE AND HOW EACH CONTRACTOR IS REIMBURSED?

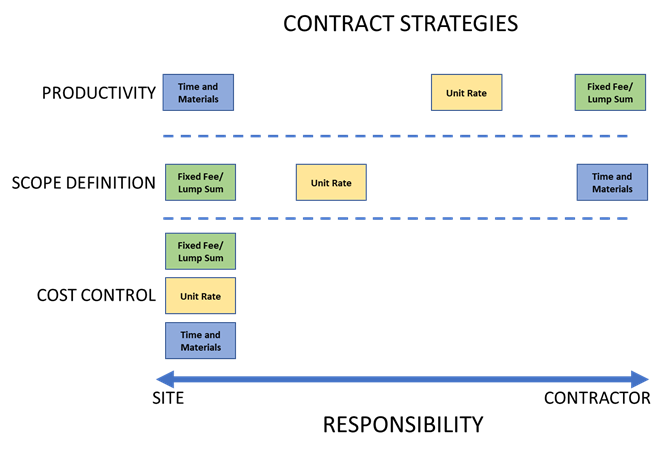

There are many contracting strategies that facilities use. Among the most popular are: Time and Materials, Unit Rates and Fixed Fee/Lump Sum contracts.

A Time and Materials contract is a structure where the contractor is paid for time spent doing the activity and for the materials used during the activity. There is little risk to the contractor for losing money as the profit is built into the labor charge and material markup. This contract structure is typically used when the scope is not well defined or if there is high chance of changes.

A Fixed Fee/Lump Sum contract is a structure where the contractor is paid for completion of an activity. There is a higher risk to the contractor and the contractor will compensate for this risk by adding cost to ensure that he doesn’t lose money. Changes to the scope require change orders and will likely have higher built-in cost negating some of the value of the fixed fee/lump sum structure. This contract structure is typically used when the scope is well-defined, ideally having been performed in the past.

A Unit Rate contract lies between the Time and Materials and Fixed Fee/Lump Sum. The contractor is paid for defined “units” of work. An example is painting where there is a price per square foot and the contractor is paid for the number of square feet that in the scope. This contract structure is typically used for repetitive tasks where the scope is known.

In a Time and Materials contract, the contractor will make more money when the job runs longer.

In a Time and Materials contract, the contractor will make more money when the job runs longer.

In a Fixed Fee/Lump Sum contract, the contractor will make more money when the scope changes.

In a Unit Rate contract, the contractor will make more money when the units are not tightly defined or when the scope includes items not defined by a Unit Rate.

Understanding the types of contracts and how each contractor is reimbursed is critical to ensuring that the proper oversight is put in place.

DO THE CONTROLS IN PLACE MATCH THE CONTROLS NEEDED?

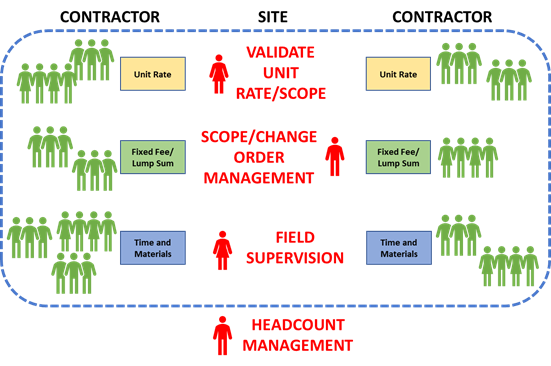

Each type of contract requires a different method to control costs. In a Time and Materials contract, the site focuses on the productivity of the contractor to ensure that the scope is safely performed as efficiently as possible with the required quality. In a Fixed Fee/Lump Sum contract, the site focuses on ensuring that the original scope is accurate and then during execution focuses on controlling scope changes. In a Unit Rate contract, the site focuses on ensuring the scope fits within the defined units.

There is typically a mix of contract types that need to be managed on a site, each requiring a different control from the site maintenance team. A maintenance team may be dealing with several contractors each with a different reimbursement structure or a single contractor that is reimbursed in several ways.

An example is a contractor with a Unit Rate contract, but any activity not covered by the unit rates is done on a Time and Materials basis. In addition, the contractor does some fixed fee work. In this example, the maintenance team needs to confirm that the scope for unit rate activities is appropriate (i.e. not using the unit rate for pump overhaul when a single component needs replacement), control the scope of the fixed fee work and monitor the productivity of Time and Material activities.

An example is a contractor with a Unit Rate contract, but any activity not covered by the unit rates is done on a Time and Materials basis. In addition, the contractor does some fixed fee work. In this example, the maintenance team needs to confirm that the scope for unit rate activities is appropriate (i.e. not using the unit rate for pump overhaul when a single component needs replacement), control the scope of the fixed fee work and monitor the productivity of Time and Material activities.

Ensuring that the proper controls are in place for each type of contract is critical to ensuring that the contracting strategy delivers the designed benefit.

CONCLUSION

Having a process in place that incorporates understanding and controlling the number of contractors on site as well as ensuring that the correct contract controls are in place are key to controlling contractor costs. There are supporting tools available on the market which can help with understanding contractor presence and ensuring that the contractor is paid in accordance with their contract terms. If you have trouble envisioning how to get started, Becht can help with assessing your situation and helping you implement the path forward.

Have a question for our experts about Becht’s experience in your maintenance process? You can contact us by clicking the link below: