World Crane and Transport Summit

This October, Becht participated in the annual World Crane and Transport Summit (WCTS). I presented on “Super Heavy Lifting” this year. It was the third time in ten years that I was invited to speak. The Summit was held in Singapore and John Koo represented Becht with me. It was a great event, attended by delegates from across the globe.

The focus of the summit this year was on green cranes and transporters and the transition to zero emissions. Many manufacturers are already offering hybrid and full electric cranes and transporters. Hydrogen powered lift and transport equipment is also under development.

The main topics discussed at the event were the transition to renewable energy worldwide.

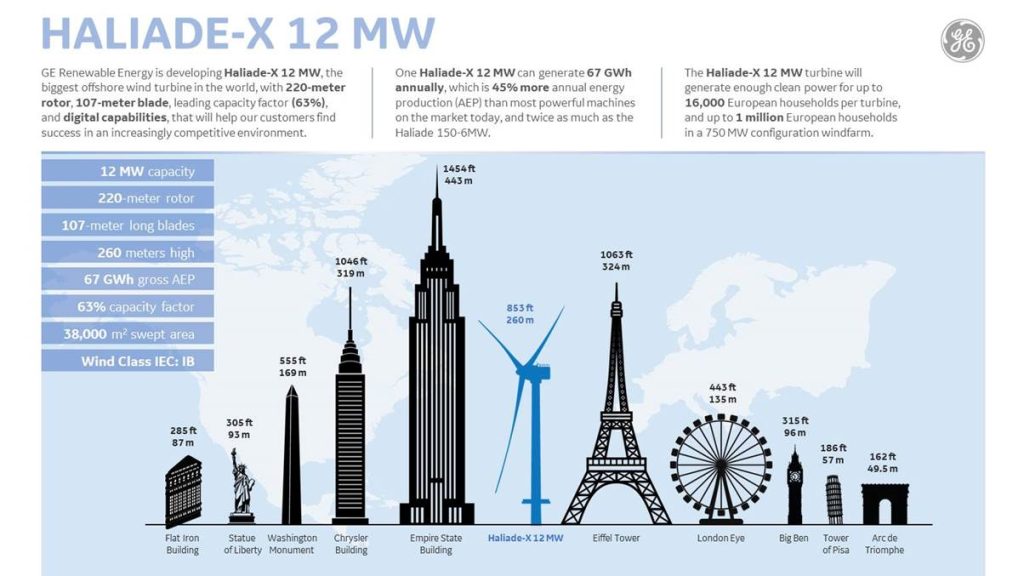

The new wind turbines are increasing in size and weight resulting in the need for larger onshore and offshore cranes. Blades are reaching lengths over 350 feet long and nacelles are weighing 700 to 1000 tons. The Vestas 15 MW turbine is 920 feet tall and has a rotor diameter of 774 feet.

The largest cranes in the world are required for the erection of the massive turbines and are already in high demand for industrial projects. There is already a major shortage of these cranes as multiple wind projects proceed simultaneously. In addition, the size of the wind turbine components make transport from the factory to construction site more complicated. The lift and transport equipment needed to handle these components is very expensive and there are long lead times to manufacture this equipment. A 3500-ton crane can take up to two years from the time it is ordered until delivery.

Wind Turbines are already skyscraper-sized – is there any limit to how big they will get?

Blog on the erection of the Haliade-X 12 MW Prototype Wind Turbine Nacelle Lift

While the crane and transport companies are struggling with high equipment cost and long delivery times, the wind industry is driving down the budget for lift and transport. The incentive to purchase new equipment is fading due to unacceptable return on investment.

The permitting process, globally, is a major cause of delays for renewable energy projects. It takes longer to permit a wind farm than it takes to build it. Anchoring the permit process with central agencies will help with streamlining.

The erection of giant offshore wind turbines presents more cost and complications. The super heavy equipment needed for this is practically non-existent today.

Turbine supply chain issues have plagued the wind turbine manufacturers. The world’s biggest turbine maker Vestas announced that supply chain issues and slow approvals for new wind projects continue to hit the firm throughout 2023 and declared a quarterly loss.

These bottlenecks and others will severely affect the world from meeting the goal of 50%carbon reduction by 2030 and further to meet “0” emissions by 2050. These are extremely ambitious goals and if the bottlenecks are not resolved they cannot be met.

Energy transition is a journey that we are all navigating. If you would like more information about Becht’s efforts, contact us to see how we can help you plan and prepare.

Any questions or comments? Please contact us: