Sling Angles do Matter!

One of the most overlooked considerations when designing a rigging system is sling angles.

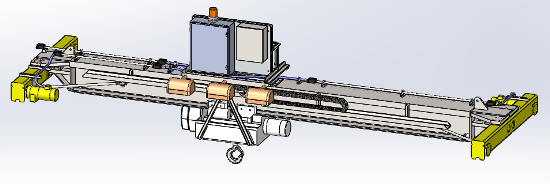

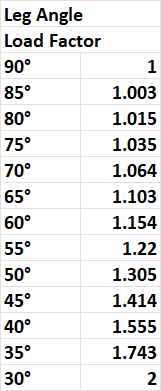

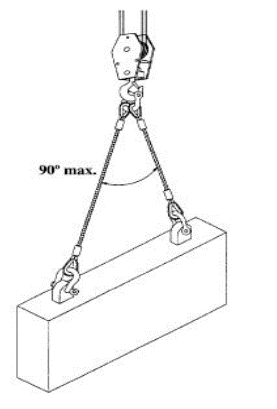

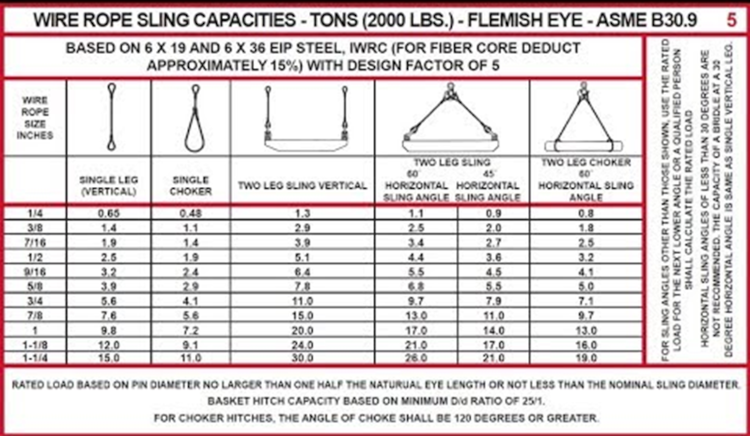

When slings are used in a bridle at an angle, the angle increases the force applied to each sling and the rigging hardware such as shackles, spreader bars, links and collector rings. The illustration below clearly shows the effect of specific sling angles on capacities. The sling attachment points are located at an equal distance from the object center of gravity.

To demonstrate this effect, imagine holding a one-gallon bucket of water in each hand. When the buckets are by your side your arms will be vertical. It is not that difficult to hold them this way.

Now, try lifting your arms up, moving the buckets away from your body. Gravity is pulling the buckets down the same as it was before but your arms will feel the force increase. This is the same effect the slings feel.

On light loads when slings are at a low percent of capacity the effect is not critical. However, if you are using the slings at or near capacity it is important to consider the sling angle effect. In this case, it is very easy to overload the slings and rigging gear.

Let’s look at the 30-degree angle. Assume your two slings have a capacity of 5,000 – pounds each and your load is 10,000 pounds. It is intuitive to think each sling will have half the total load. However, if the slings are at 30-degrees, the force applied is 10,000 pounds for each leg. In this case the slings could be overloaded by 100 percent!!! The same tension is applied to the other hardware in the system and will likely be overloaded as well.

It is very easy to calculate the tension for slings used at an angle. The engineering folks have worked out the forces for various angles and assigned a multiplier to each angle. Note the table in the illustration. The multiplier corresponds to the given angle.

Example One: Two Leg Bridle

To calculate the force on each leg of a bridle:

Start with the total weight of the load;

Divide the total weight by the number of slings;

Then multiply the dividend by the “Leg Angle Load Factor” from the table;

The product will be the force on each leg.

-

-

-

-

-

-

-

-

- Load = 100,000 pounds

- Number of slings – two at 45 degrees

- Angle Load Factor for 45 degrees is 1.414

- 100,000 / 2 = 50,000

- 50,000 * 1.414 = 70,700 pounds force on each leg

-

-

-

-

-

-

-

You can clearly see the significance in this case. If one were to rig that load without considering the sling angles each sling has the potential to be overloaded by 20,700 pounds!!!

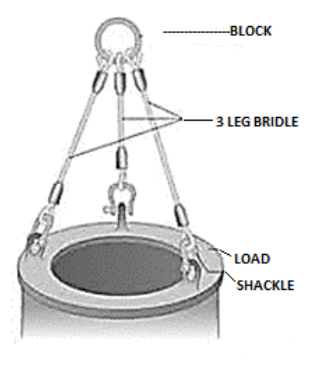

Example Two: Three Leg Bridle

-

-

-

-

-

-

-

- Load = 200,000 pounds

- Number of slings – three at 60 degrees each

- Angle Load Factor for 60 degrees is 1.154

- 200,000 / 3 = 66,666

- 66,666 * 1.154 = 76,982 pounds force on each leg of the bridle

-

-

-

-

-

-

In this case you could potentially overload the slings by 10,316 pounds each!!!

The sling manufacturers have created capacity charts for their products and included a limited number of sling angle configurations in the tables. These are very helpful but do not include every configuration. One should always do a quick sling angle calculation to assure you are sizing the slings and rigging gear within rated capacity.

Slings are designed with a 5 to 1 safety factor. I often hear “you don’t have to worry about the sling angles because that is what the safety factor is for”.

WRONG – the safety factor is there to allow for capacity reducing – wear and tear, dynamic forces, unbalanced loads and ultimately, shock loads. Never use the safety factor to exceed the capacity chart ratings.

I also hear that when using a four leg bridle you should size the rigging as if only three legs will take the entire load. The thought is that one leg could be longer causing the remaining three to take the full load.

I disagree with this practice – if you use quality rigging from reputable manufacturers and use care to match up your slings, there will not be a problem. The slings tend to stretch when loaded and will equalize the forces. It is true that one or more will see more load than others but if they ae reasonably close to the same length, the difference in the forces applied to each leg is negligible and accounted for by the safety factor. Manufactured four leg bridles do not derate one or more of the legs in the system. All four legs are rated at full capacity. On very heavy loads, hundreds of tons, applying the full load to three of four legs results in gross oversizing of the slings. This not only increases cost but also adds unnecessary weight to the system.

Caution: if you have a gross mismatching of sling length there is a problem

and counting on three to take the load is not the solution. Go get ones that match.

In conclusion, sling angles do matter. If not considered, the rigging gear can be severely overloaded to a point of failure. Utilize the manufactures capacity charts and perform the simple calculations for angles that are not included in the charts. When using the Angle Factor Load Table, use the next larger load factor when the angle falls between the values on the table.

Have a question about your lift angles and load calculations?