Purpose of the Flange Bolt Rules in ASME VIII and ASME III

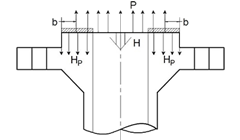

The partial objective of the ASME Appendices ASME VIII Div.1 Appendix 2, and ASME III Div.1 Appendix XI provide “Rules for Bolted Flange Connections” with ring-type gaskets. One of the rules provided applies to the calculation of the minimum required bolt area. In other words, what should be the minimum combined cross-section area of the […]