Estimating Creep Life of Fluid Catalytic Cracker Internals Using FEA

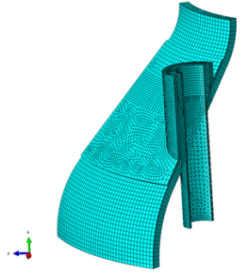

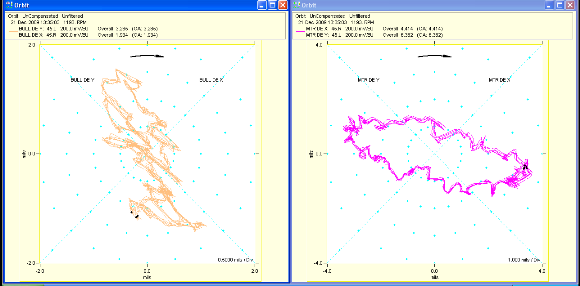

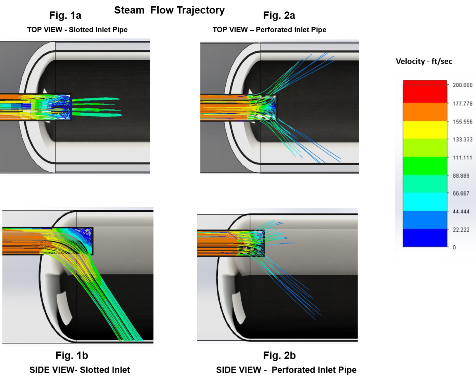

How long will the cyclone system in a Cat Cracker reactor or regenerator last? Cyclones systems in Fluidized Catalytic Cracker units (FCC) are typically designed to a creep allowable stress, where the stress field at various locations of the system has been determined by linear elastic analysis. The basic allowable stress for such internal structures […]