State Approval of Used or Relocated Pressure Vessels

Achieving “State Special” designation for a pressure vessel can require a fair amount of effort in documentation development. This process is warranted – for example – when a company wants to move a pressure vessel from one facility for operation in a facility located in another state, or when they purchase a used vessel located in another country or state for use in the United States. The vessel may or may not have been constructed to the rules of the ASME Boiler and Pressure Vessel Code or ASME Code stamped. A question that typically arises, “Are there regulations governing the relocation/reuse of such vessels?” The answer is “Yes” and the regulations are found within the state agency, e.g. the Department of Public Safety, the Department of Labor that has jurisdiction over both the construction of new boilers and pressure vessels, and inspection and repairs of existing equipment. It is headed by the state’s Chief Boiler and Pressure Vessel Inspector who is a member of the National Board. The document “The National Board Synopsis of Boiler and Pressure Vessel Laws, Rules and Regulations” is a summary of each state’s (and Canadian Provinces) laws, rules, and regulations. It also lists the contact information for the Chief Inspector and state agency responsible for boiler and pressure vessel regulations. The documentation is available at http://www.nationalboard.org/ViewAllSynopses.aspx. It is the recommended starting point for understanding the state regulations

For new vessels, meeting the Code requirements for design, fabrication, inspection and testing, and Code stamping reside with the vessel fabricator. In most states, ASME Code Section VIII construction has been adopted into the state regulations. The movement of used vessels into a state or from outside the U.S. into the state is within the jurisdiction of the state where the vessel is to be operated. It has been Becht’s experience that these vessels can be brought into the state and are designated as “State Specials” or “State Approved” pressure vessels. There is an application procedure and a fee of $3,000 to $4,000 per vessel. The procedure is aimed at showing that the vessel is equivalent to ASME Code construction. In our experience, the fee is relatively small compared to the effort required to develop the documentation in support of the Application – this is especially true for older vessels where documentation is often missing. One resource for managing used equipment is the Material Technology Institute’s publication “Inspection and Use of Equipment with Missing Documentation”; this document was developed by Becht Engineering and was published in June 2015.

There are a number of documents that must be filed with the Application. The Application and documents appear to be similar across states and typically require the following:

- A general arrangement drawing showing major pressure components, e.g., heads, shell, nozzle numbers and size, materials of construction, design conditions and design code. In a number of cases Becht developed the drawings for a client (user); either the vessels were more than 20 years old and the drawings could not be found, the drawings were illegible, or the vessel fabricator was no longer in business. In these cases, it was necessary to obtain field measured dimensional data to make new drawings. A photograph or rubbing of the vessel nameplate is very useful in this effort.

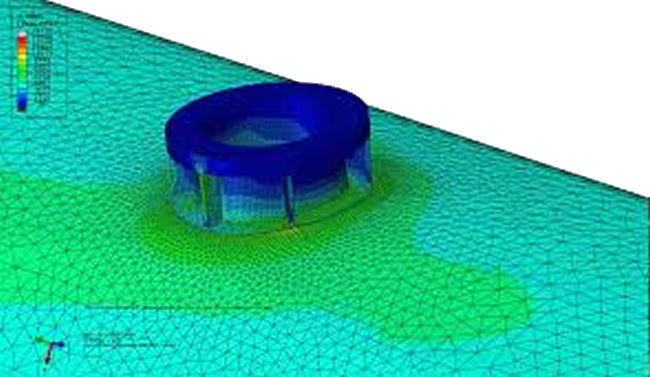

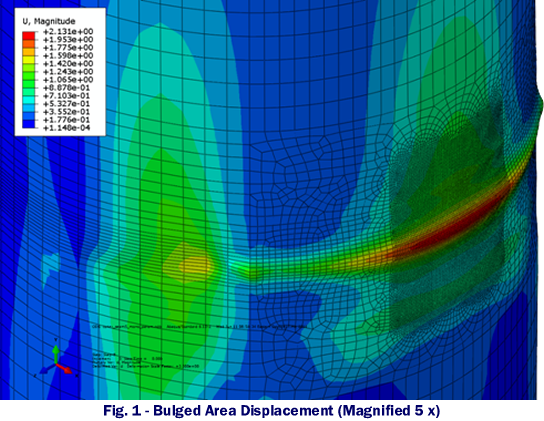

- Calculations demonstrating equivalency to ASME construction. Similar to the drawings, the calculations may have been misplaced or lost over time. This requires running the calculations using industry pressure vessel design software such as COMPRESS or PVElite. In certain cases, Finite Element Analysis (FEA) is necessary to demonstrate the equivalency of a vessel component which may have been designed and constructed to a different code. For example, vessels constructed to foreign codes may have different allowable stress bases, materials designations, and calculation methods. These will need to be addressed/reconciled in the calculations.

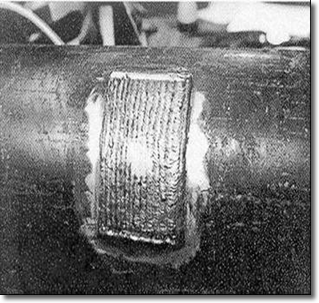

- Documentation of appropriate welding procedures and inspection results from original construction of the vessel. We have found that this information is generally not available; however, the states have accepted the results of an inspection as a part of the application procedures. In this case we developed an inspection program to demonstrate the welds are “defect free” within the requirements of the ASME Code. If spot radiography was used for inspection during original construction, there is a risk of finding weld defects which may not have been found using spot radiography during construction. This may require a fitness service assessment per API 579-1/ASME FFS-1, to determine if a repair is necessary. All repairs should be made by an “R” Certificate Holder, i.e., a firm authorized by the National Board to repair pressure vessels.

Part of Becht’s inspection program typically includes inspection for known damage mechanisms, e.g., general/local corrosion, wet H2S cracking, pitting, etc., that may have resulted from the vessel’s previous service environment. Inspection identifies any damage present, its extent and a fitness-for-service assessment would be required to determine if a repair is required.

- Although not required by the Application, Becht Engineering conducted and submitted with the Application a “mini-HAZOP”. It was conducted jointly with the client’s staff knowledgeable in the vessel operation and Becht’s safety/risk specialist. The objective was to review vessel operating environment for any process safety issues and to review the overpressure contingencies that set the vessel relief valve requirements. In one case the review was requested by the Chief Inspector.

After completing the Application and required documentation, a letter signed by the client (user) is sent to the Chief Inspector along with the Application and documentation requesting that the “State Special” designation be approved by the state. The letter also includes a brief description of the vessel’s use, the substances to be contained in the vessel and the proposed pressure and temperature conditions. The drawing and calculations require the verification and stamp of a registered professional engineer knowledgeable in pressure vessel design. If “State Special” designation is approved, the vessel is registered in the state and identified as such, e.g., in New Jersey, and a new nameplate is affixed to the vessel by a National Board Certified Authorized Inspector.

If you need certification assistance for a pressure vessel, please click the button below:

Click to Request More Info from Becht

Have a question or comment??? You may post it on this blog. Scroll Down.