Are Your Heaters Affecting Your Reliability?

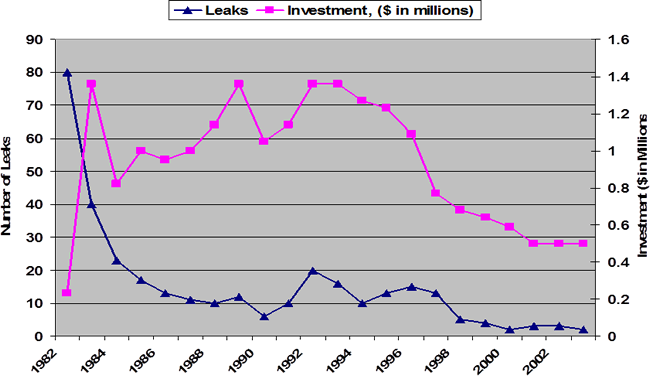

From a process standpoint, your Fired Equipment items are not only some of the most critical but some of the most risky items in day-to-day operations. Add in the presence of open flames and failures can be dramatic. In today’s refining climate, fired equipment is required to run 4, 5, 6 or even 7 years […]