Integration Of Integrity Operating Windows Into Process Safety Management

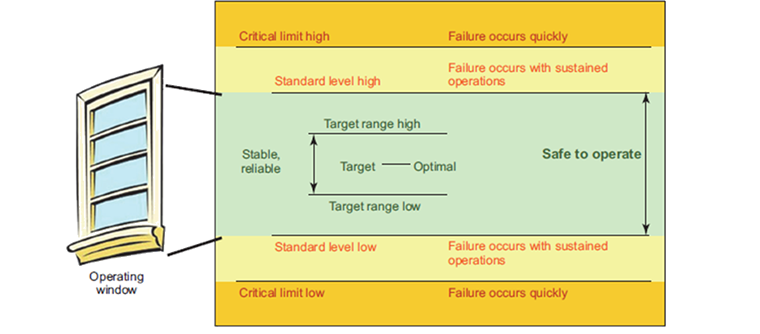

Integrity Operating Windows (IOWs) are an important component of a world class mechanical integrity program. IOWs are not a new concept, as they have been around in different forms for many years. However, due to some recent high-profile industry indictments and with the publication of the first edition of API RP 584 Integrity Operating Windows […]